News

What is the function of the rotor in a three-phase motor

In a three-phase motor, the rotor interacts with the rotating magnetic field of the stator

What determines the type of three-phase motor

The type of a three-phase motor depends on factors like rotor type, speed, and load.

How is a three-phase motor with six wire leads connected

A three-phase motor with six leads is usually connected in either a star (Y) or

How to identify 3-phase motor windings

To identify 3-phase motor windings, measure resistance between terminals using a multimeter. Each winding (e.g.,

What is the construction of a three-phase induction motor

The three-phase induction motor mainly consists of the stator, rotor, bearings, cooling system, and protection

Development history of three-phase asynchronous motor

The development history of the three-phase asynchronous motor began with the theory of polyphase current

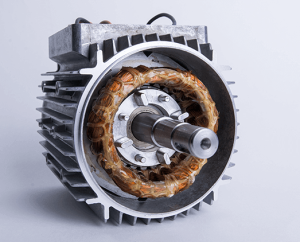

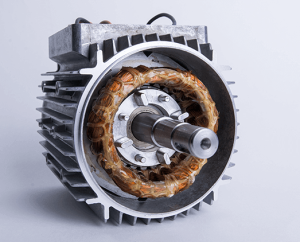

What is the function of the rotor in a three-phase motor

In a three-phase motor, the rotor interacts with the rotating magnetic field of the stator to convert electrical energy into mechanical energy, thereby driving the load. If the rotor overheats

What determines the type of three-phase motor

The type of a three-phase motor depends on factors like rotor type, speed, and load. For example, a 50 Hz, 4-pole motor achieves 1500 RPM, ideal for conveyors. A 200

How is a three-phase motor with six wire leads connected

A three-phase motor with six leads is usually connected in either a star (Y) or delta (Δ) configuration. In a star connection, the ends of the three-phase windings are connected

How to identify 3-phase motor windings

To identify 3-phase motor windings, measure resistance between terminals using a multimeter. Each winding (e.g., U1-U2, V1-V2, W1-W2) should show similar resistance, typically 1-2 ohms for a 7.5 kW motor.

What is the construction of a three-phase induction motor

The three-phase induction motor mainly consists of the stator, rotor, bearings, cooling system, and protection devices. The stator generates a rotating magnetic field that drives the rotor. The cooling system,

Development history of three-phase asynchronous motor

The development history of the three-phase asynchronous motor began with the theory of polyphase current in the late 19th century, proposed and gradually refined by Tesla. The early motor structure

Can a 3-phase motor be run on single-phase

Yes, a 3-phase motor can run on single-phase power using methods like a rotary phase converter, static phase converter, or VFD. For example, a 5 hp motor needs approximately 23

Does a 3-phase motor need a capacitor

No, a 3-phase motor typically doesn’t need a capacitor, as it achieves self-starting with its rotating magnetic field. For instance, a 10 kW 3-phase motor provides full torque immediately without

How are three-phase motors balanced

Achieving balance in a three-phase motor is primarily done by ensuring symmetry in the voltage, current, and load across all three phases. First, use a voltmeter and ammeter to measure

Why does a three-phase motor induction run without capacitors

Three-phase motors naturally create a rotating magnetic field due to the 120-degree phase difference in the three-phase current, directly driving the rotor’s rotation without the need for capacitors to assist

How to control the speed of a 3-phase induction motor

To control the speed of a 3-phase induction motor, you can use methods like VFDs (Variable Frequency Drives) to adjust frequency, which directly controls speed. For example, reducing frequency from

How can I reduce the RPM of a 3-phase motor

There are several ways of decreasing the speed of a three-phase motor: variable frequency drive, voltage regulator, gear reducer, among others. A VFD can accurately control motor speed with high

What are the starting methods of three-phase induction motors

The following are the various three-phase induction motor starting methods: Direct start; Star-delta start; Autotransformer start; Soft starter; And Variable Frequency Drive (VFD) control. A direct start technique is simple

What are the common problems found in a 3 phase motor

The common faults that appear in three-phase motors include overheating, imbalance in voltage, bearing failure, breakdown of insulation, problems in power supply, misalignment of the motor, and rotor failure. The

Why do 3 phase motors not need a neutral

Since the current in each phase in a three-phase system is balanced, and with a phase difference of 120 degrees, the sum total current approaches zero, the neutral line is

What is the difference between a three phase motor and a two-phase motor

These are the basic differences between a three-phase and a two-phase motor: the number of power phases and the application. A three-phase motor takes in three power lines carrying currents

7 reasons to use three-phase motors

It is due to higher efficiency, lower operating costs, superior reliability, smooth operations, compact design, improved power factor, and easy maintenance. It is mainly because three-phase motors are able to

What happens if you run a 3-phase motor on single-phase

Operation of a three-phase motor on single-phase power supply results in non-balanced current distribution inside the motor. A motor is under an unbalanced load condition, whereas two windings would carry

How do you maintain a 3-phase motor

The maintenance of the three-phase motor involves routine checks for wiring to be secure, balanced three-phase voltage within ±5% to avoid overheating. The bearings should be lubricated with appropriate grease

Is a three-phase induction motor AC or DC

A three-phase induction motor works on the principle of an alternating current instead of direct current. It requires a three-phase AC power supply for creating a rotating magnetic field in