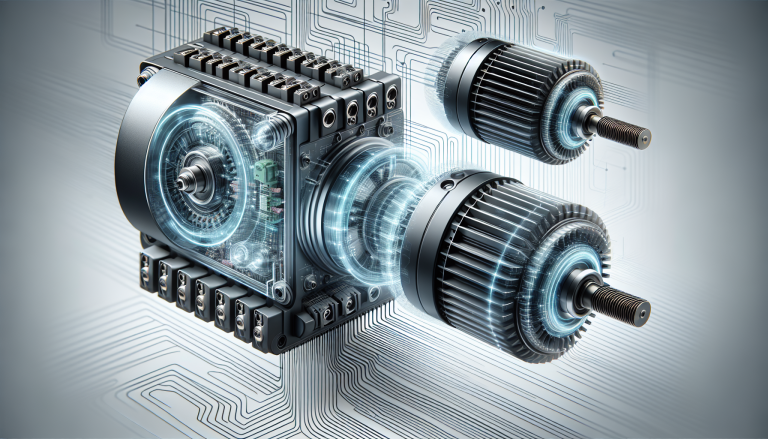

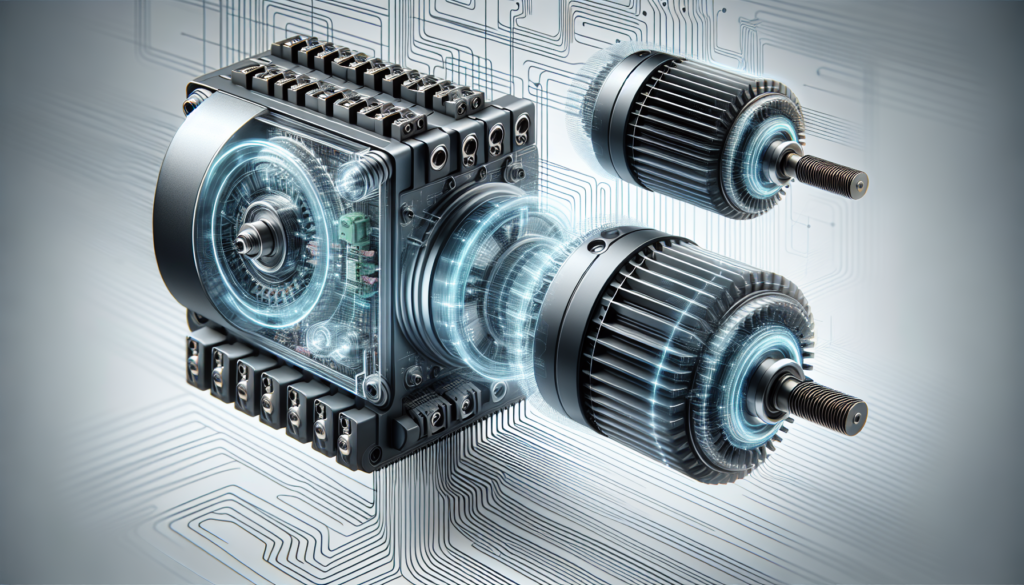

The efficiency of three-phase motors is higher than 90%, their power can reach several hundred kW, so they are suitable for industrial equipment compared with single-phase motors, the starting torque is around 2-3 times. The efficiency of single-phase motors is low at around 80%, but it is smaller than that(usually within 15 kilowatts) and more suitable for household or lower power equipment.

Table of Contents

ToggleStarting Methods and Performance Differences

Three-phase motors have a higher starting torque compared to single phase with 2~3 times, so that they provide high startup power, ideal for machines that require more supply at startup. Single-Phase Motors must have additional starting devices, such as capacitors or split-phase windings. Not only do these extra components add to the cost, but they can also reduce the durability of the motor.

From a performance perspective three-phase motors operate at an efficiency of over 90%, where single-phase motors are around 80–85%. Three-phase motors can save more energy in long-term operation, which is very significant especially in industrial applications, due to their high efficiency. Power factor: The power factor of three-phase motors is usually much closer to 1 than that of single-phase motors, which often have a power factor around 0.8 or lower this allows them to consume more electrical power effectively since there is very little power wasting.

Regarding starting methods, single-phase motors rely on start capacitors and auxiliary windings, while three-phase motors naturally start through balanced three-phase power without the need for additional starting devices. This not only simplifies the design of three-phase motors but also improves their overall reliability and maintenance convenience. Three-phase motors generate lower vibrations and noise during operation, running more smoothly, which is especially important for equipment that needs to run continuously for long periods.

Efficiency and energy saving analysis

| Aspect | Single-phase Motor | Three-phase Motor |

|---|---|---|

| Efficiency | ~80-85% | ~90%+ |

| Power Factor | ~0.8 | ~1.0 |

| Energy Consumption | 2200 kWh per year (15 kW) | 2000 kWh per year (15 kW) |

| Maintenance Cost | Higher maintenance costs | Maintenance costs lower by ~30% |

| Power Rating | Up to 15 kW | Up to several hundred kW |

| Investment Cost | Lower initial investment | Higher initial investment |

| Usage Application | Household appliances, small equipment | Industrial production lines, large pumps |

| Lifespan | Shorter lifespan | Up to 20+ years |

Application Environments and Scene Selection

Single-phase motors are used primarily in household appliances, such as air conditioners, washing machines, refrigerators, and small fans and other domestic or light-industrial equipment with applications requiring only intermittent use. Because single-phase power is more than 95% prevalent in residential areas, it is best to use a single-phase motor for household appliances. Less expensive installation and repair due to single-phase motors, also great for applications with small projects or budgets.

Three-phase motors are mostly used in industrial and large commercial areas, such as production pipelines, pump stations, compressors, big fans, and so on, with power performances usually ranging from tens of kilowatts to numerous hundred kilowatts for meeting the demands of high-load devices. Industrial areas provide relatively large power supplies for the three-phase power sources suitable, high electrical transmission efficiency, and in contrast to household units, these machines can work unchanged for a long period. Large lighting equipment is also commonly used in three-phase motors in commercial buildings to stabilize the power supply of elevators and central air conditioning systems.

Installation and Configuration Requirements

Three-phase motors need three lifeline and one zero line with more wiring complexity and costs. The voltage of the single-phase motor is generally 220V or 380V, and a three-phase motor with a kilowatt of about 100 may weigh several hundred kilograms, while the single phase is much smaller. Three-phase motors have more complicated cooling systems, which are usually air-cooling with a windmill or water-cooler to keep the temperature stable at lights out of high loads causing large powers loss, since single-phase motors only require minimal cooling and simply use natural ventilation.

The way we use the grounding measures is as important in single-phase motor installations as well in three-phase. Generally, the connection method of single-phase motors is a common grounding wire to connect. However, for three-phase motors with higher power and more complex wiring requirements, safety integrity must be improved through a stronger way to prevent electric leakage during operation. The extensively adopted nationwide electrical standards require that three-phase motors ground less than 4 ohms.