The advantage of a three-phase motor lies in its over 90% energy conversion efficiency, suitable for driving high-power equipment above 100kW, providing 150% starting torque during startup, while reducing equipment downtime and enhancing production line efficiency.

Durability of three-phase motors

The main attribute of three-phase motors is amazing durability and their lifespan can reach 15-20 years. Since this service life is very long, factories and equipment operators can greatly reduce the frequency of equipment replacement over time and save up to 30% on maintenance costs. Within the industry, equipment needs to run reliably over the long-term under high-load conditions.

Three-phase motors are also tested for high temperature conditions and severe environmental hazards to prove their durability. Remain stable power output in 50°C high-temperature conditions, and environments with high levels of dust and humidity for three-phase motors. This brings a high level of reliability to the equipment, which it consequently makes it a favorite for use in high-intensity industries like mining, oil & chemicals. The motors themselves are smaller in structure, which streamlines changes to the assembly layout within the production machines and equipment, leading to less wear over an extended period of use. This custom design will enable devices to drive substantial production line efficiency improvements with no more floor space.

Suitable for high-load industrial equipment

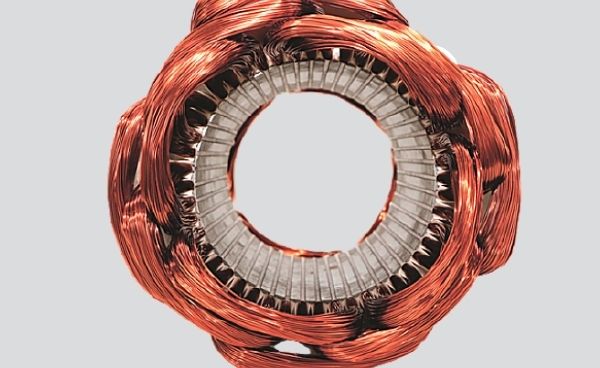

In high-load industrial equipment, three-phase motors are more than likely to be found at work compared to traditional single phase that is under 50kW, delivering perfectly stable performance with energy efficiency to boot. Three-phase motors are nearly immune from single Phased loads and can handle short term load variations in the range. Due to the large power output of three-phase motors and durable characteristics as well, many production lines and large machinery used in high-power industries, such as metallurgy, mining, and papermaking.

Three-phase motors have up to 95% energy conversion efficiency under high-load conditions, which makes them more efficient than the traditional single-phase motor option. They will be able to save up to 20% on electricity costs annually by reducing energy losses. Due to the constant torque output of three-phase motors, a stable power supply can be provided in spite of changes in load ensuring that downtime is minimized and production efficiency is maximized.

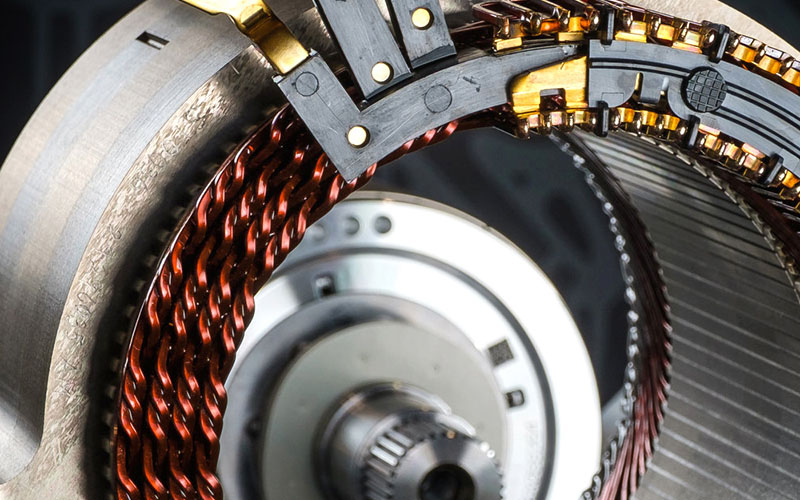

Three-phase motors are designed with the extended operation requirements of industrial equipment in mind. Three-phase motors are stable and durable in 24-hour operation environments. These encapsulants can endure the mechanical stress that frequent starts and stops create, which reduces component wear and extends equipment life, generally by roughly two years. Single-phase motors are generally more maintenance-intensive under similar working loads as opposed to more commercially-standard three-phase designs. Balanced three-phase power supply system, reduce the electromagnetic interference generated by motor operation, does not affect the equipment from the impact of power grid fluctuations.

Low maintenance costs of motors

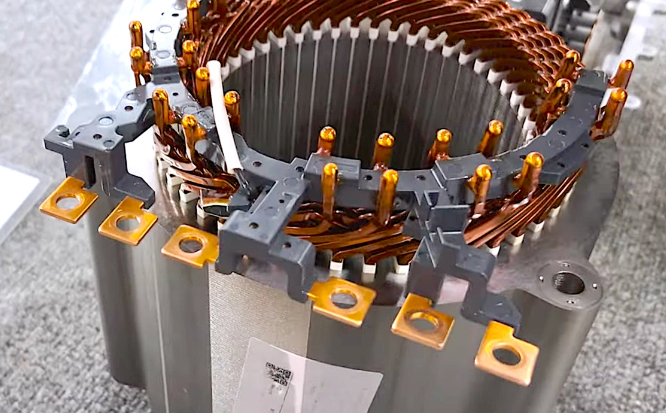

Three-phase motors enjoy an outstanding reputation because of their low maintenance costs. Three-phase motors have a simple design, with no capacitors or start switches to fail. Under an operating mode of 10 hours a day, a three-phase motor can run for more than 3 years without needing significant maintenance. In addition, extending the operating time of equipment is realized with less disruption on factory operation.

Three-phase motors are another high energy efficiency design that plays a key role in lowering maintenance costs. Efficient operation not only reduces energy expense, but also significantly reduces wear on long-running equipment which in turn reduces further maintenance expenses. In addition to the above, the three-phase motor is also highly durable, as it has a more reinforced structure which supports extreme conditions – for example high temperatures, humidity, or dust. This minimises any risk associated with failures/maintenance due to environment. Since adopting three-phase motors, a large percentage of factories have witnessed reductions in maintenance costs by as much as 15-20% particularly in high load settings where these savings are even more pronounced.

With three-phase motors, the load is evenly balanced across its windings (in most cases) so that their mechanical stress is also more uniform during operation ensuring a long lifespan of all components. Three-phase motors can be extended to between 12 and 18 months on the maintenance are not frequent maintenance, this need makes the equipment operation more efficient.

Improving production efficiency

They offer a constant power output, up to over 90% conversion efficiency under high load in order to reduce downtime due to insufficient power during operation. Three-phase motors have more power than one phase, which makes them capable of driving a heavier load and run efficiently with high-power rating up to 100kW compared to single phase. It streamlines production line operations, promoting labor efficiency at large.

AC three-phase motors have a higher torque output as well, specifically while starting, delivering twice (200%) the starting torque — this results in more available passenger power for equipment to start up and quicken equipment readiness. This rapid response capability is important 4 assembly line of sections, especially for production lines that tend to stop and go repeatedly, can directly save time and level productivity therapeutically.

Three-phase motors are designed to operate 24 hours a day with stable and efficient performance in long-term operation environments. This opens up the possibility to utilize three-phase motors in industry applications where downtime can be minimized, which should have a positive effect on equipment utilization and production line efficiency. Organizations using three-phase motors are experiencing an enhancement of 20-30% in equipment operating time, leading them to enhanced level of productivity. Three-phase motors are a balanced system, and three-phase electric power supply is also a balanced system to allow the motor to work stably while ignoring the changing load.