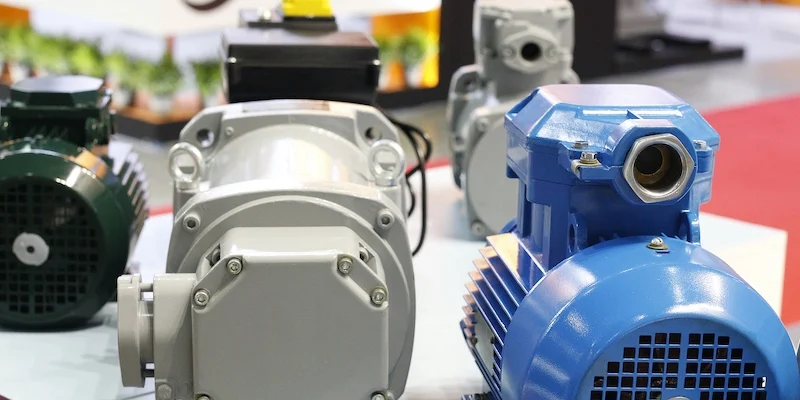

Three-phase motors are used to efficiently drive high-power equipment and are widely applied in industrial, agricultural, and mining sectors. With an efficiency typically exceeding 95%, they provide stable power output, making them ideal for driving equipment with a power rating of over 50 kW, such as water pumps, compressors, and mine hoists.

Three-phase motors in industrial applications

Three-phase motors dominate the huge number of factory automation equipment in terms of center, accounting for more than 90%. Since three-phase motors have memorialized their caveat efficiency and stable performance with them, especially in a large industrial use. These motors are designed in a way that they deliver constant output power, which contributes in the stability of the equipment over longer period of time while operation. Three-phase motors can increase power output by as much as 50% compared to single-phase motors, which is vital for optimizing production efficiency. Three-phase motors are utilised by a variety of heavy equipment including heavy machinery, compressors, and pumps. For the continual operation of these machines, an even higher power-rated motor above 75 kW is generally used. This is possible in such industries as metallurgy and chemicals, where the power rating and speed of three-phase motors can be adjusted exactly to the requirements of equipment for obtaining maximum performance speeds.

The typical life of these motors will be around 15 to 20 years which is far more than other mechanical devices. This will help you save on costs and downtime from replacing it. For companies that do use three-phase motors, the high operating efficiency (around 95%) allows for fast return on investment as energy cost savings are easily felt. Three-phase motors are now increasingly used not only in conventional machinery but also in smart manufacturing systems. Not just CNC, the three-phase motors can run as fast as 3,000 RPM that can contribute in higher production precision and speed. In this context, the importance of the speed and torque control of three-phase motors is very important, directly reflecting on product quality and production time.

Three-phase motors in agricultural applications

Three-phase motors are generally used in irrigation systems to drive water pumps, with pump-manufactured capacities of at least 200 cubic meters/hour allowing effective support for large-area irrigation of farmland. Three-phase motors are between 30% and 40% more efficient than their conventional single-phase motor counterparts, leading to more work being done with the same energy input. Often the strong power of three-phase electric motors is used in agricultural machinery — harvesters, threshers, and feed processing equipment. In most cases, these machines will need to be 50 kW or greater in order to run smoothly and effectively over the long term.

Most multi phase motors run for at least 15 years saving farmers a lot in maintenance and replacement costs over the long haul. In a greenhouse environment specific ventilation and temperature controls driven by three-phase motor systems significantly reduce energy input while allowing growing to ideal conditions leading to maximised plant potential. A heat preservation system based on 3-phase motor can be adopted in vegetable greenhouses, energy loss can be reduced by 20%, and the production cost can be effectively decreased. In addition to machinery, three-phase motors are also very popular in agriculture wind power and solar energy systems. Three-phase motors up to about 100 kW can be used depending on the power required and are suitable for wind turbines of farms.

Three-phase motors in mining applications

Underground mines will typically use three-phase motors to drive large hoists, with ratings around or above 500 kW that can raise tens of tons of ore very quickly. Mining applications have strict motor requirements; they must have high power and be able to operate reliably over long periods without issue. Mining machines prefer to use motors with a high efficiency and little failure that is, the three-phase motor. Three-phase motors are also necessary driving forces in mining, ore crushing and grinding processes. The so-called ore grinding equipment commonly use the power demand is larger, regular motor scale is greater than 1000 kW, and in order to make high efficiency of ore processing, ore grinding need to be continuous operation. Because three-phase motors used by the mining industry are continuously active, it is estimated that mining companies using three-phase motors could reduce energy consumption by approximately 15%, which represent a lowered cost in energy expenses.

The ventilation in mines is also running on three-phase motors with stable drive. A high-power borehole fan, with a rated power of over 200 kW, may provide more than 1,000 m3/h fresh air flow to keep the mine in good ventilation condition and safe production. The mining environment is complicated, and the rugged design and high impact resistance of three-phase motors make it reach stable operation under severe conditions for more than 10 years. In the mining industry, three-phase motors are commonly used to power conveyor systems that transport ores and materials. Conveyor system motors usually run at 2 meters per minute clocking many tons of good transported through. When automated conveyor systems are driven by three-phase motors, mining operations can cut down production costs substantially and reduced risks for worker safety—all without the need to replace existing conveyors.