Three-phase motor operates by inputting three-phase alternating current, forming a rotating magnetic field with a phase difference of 120 degrees, driving the rotor to rotate. Its synchronous speed calculation formula is 120 x frequency / number of poles, and at 50Hz, the speed of a two-pole motor can reach 3000 RPM.

Power configuration of three-phase motor

Three-phase motor at the heart of a three-phase AC power supply, and each phase voltage is spaced 120 degrees away from that maintained by one another. The motor will be able to create a revolving magnetic field, which makes the rotating of consecutive poles important for clock operation, by using constant current power. Three-phase motors provide better power delivery than their single-phase counterparts, and are generally more efficient. Three-phase motors have an efficiency range of around 85% to 95%, much better than single-phase motors which somewhere from 60% to 70%.

Three-phase power supply of each phase current changes in a sinewave, these waveforms synchronization allows the electric motor to maintain stable operation,a 50 Hz(60 Hz) cycle per second,for example. Three-phase motors have the following power configuration: In this region, the voltage standards for three-phase motors tend to be 380V, 415V, or 480V different regions are using different voltages to standardize their three-phase motor to meet industrial applications. Compared with the three-phase motor, it has a lower cost for the power system maintenance since the starting current of three-phase motors is very low and almost does not affect to cause an impact on the grid during startup.

Electromagnetic induction and rotor motion

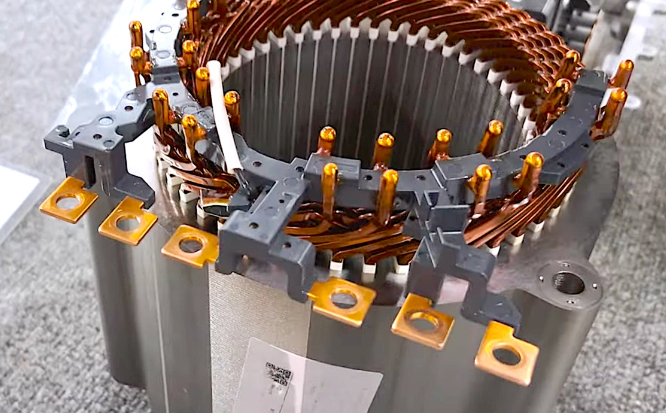

A three-phase motor function on the principle of electromagnetic induction. The three-phase alternating current flowing through the stator windings creates a moving magnetic field. The speed at which this magnetic field runs is normally called the Synchronous speed and it can be calculated using the following formula: synchronous speed = 120 x frequency / number of poles Therefore, the synchronous speed of a two-pole three-phase motor is 3000 RPM at an industrial power supply frequency of 50Hz. The rotor is passing this rotating magnetic field and as a result moves an electrical current. Faraday’s Law of Electromagnetic Induction states that if a magnetic field is caused to change at a point within a conductor, then an electric current will flow in the conductor. The rotor will in turn develop torque under the influence of magnetic field as due to induced current flowing into the rotor, a second stator magnetic field will be created within rotor machine interacting with the original stator magnetic fields, hence causing relative motion and thus generation of power. The magnitude of the torque is directly proportional to the load capacity of the motor.

Because of the load, in reality, the rotor is always a little slower than the magnetic field synchronous speed (This difference is named slip). Slip varies from 2% to 6% and the less slip, the more efficient the motor onDataChange This is part of the reason why three-phase motors tend to be favored in a host of industrial settings not only do they produce consistent power, but they can even maintain as much as 95% efficiency at reduced slip rates. The speed at which the rotor may turn and the general performance of the motor are directly impacted by how well electromagnetic induction is done efficiently. One of the most targeted areas of a motor in an induction based system is the capability of a motor to run faster with less power consumption, typically upto 3500 RPM and this is highly desired for various industrial applications which demand higher speeds.

Working process of three-phase motor

A three-phase motor operates by feeding it with a three-phase AC voltage (phase travel in each phase is 120 degrees), which creates a rotating magnetic field on the stator. The mutual speed at which this magnetic field rotates is known as synchronous speed and its degree of calculation can be: Synchronous Speed = 120 x frequency/poles. A two-pole motor has the synchronous speed of 3000 RPM at 50Hz of the base frequency. This causes a current to be induced in the rotor, and the Rotor magnetic field interacts with the Stator magnetic field. The reacting magnetic field causes the rotor to produce torque, making the rotor rotate. As a general rule, the torque output of a three-phase motor is proportional to the load. For example a motor with 15 kW rated power can continuously produce stable torque under its load on the same rating.

The rotor speed approaches synchronous speed while the motor is running, however because of the load, this speed slightly less than syn chromosonic so there is a slip. The slip is normally around 1–5 %, depending on the load size and the motor design. The less the slip, the more efficient are the motor. Certain high-efficiency three-phase motors, for example, can yield > 90% efficiency at the rated load. The motor changes the output of torque when the load is changed. In high-load cases, the slip increase slightly to maintain adequate torque output of the motor while at low-load points, the slip decline and thus attended with a reduction in power consumption of the motor. The motor speed is fully controllable up to the top speed, it can smoothly change from 0 rpm to the maximum speed with variable frequency control.