Phase sequence in a three-phase motor would determine its rotation direction and stability of operation; a wrong phase sequence will only result in the motor reversal, efficiency loss, and equipment damage. For safety, it is recommended that the phase sequence should be checked using a phase sequence tester after the installation of the motor or wiring.

What is Phase Sequence

Phase sequence means a sequence of phases through which three-phase AC voltage varies and is usually named L1, L2, and L3. Ideally, the separation between these three phases is 120 degrees and generates a rotating magnetic field. When a three-phase motor is connected to power, phase sequence determines the rotation direction of the magnetic field, hence setting the motor rotation direction. The usual phase sequence is L1, L2, L3 in succession to make sure that there is clockwise rotation of a motor. In incorrect connections, such as at L2-L3, the direction of the magnetic field is reversed, which gives counterclockwise rotation.

The phase sequence determines not only the rotation direction but also directly affects the current distribution in motor windings. If there is a deviation in the phase angle of three-phase voltage, the balance of current is destroyed, and it will directly influence the service life and efficiency of the motor. The testing of the sequence of phases is thus indispensable in commissioning, installing, or even maintaining motor equipment. Using a phase sequence tester effectively avoids wiring errors that may put the motor in its designed operating state.

Role in Motor Performance

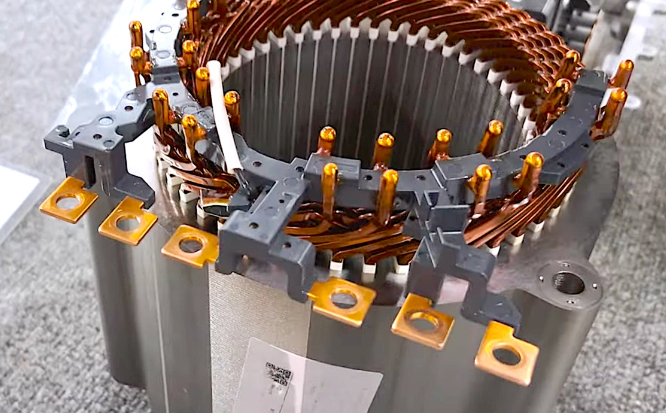

The performance of any motor highly depends on whether its phase sequence is correct, especially for those high-power ones that require operation continuously in a stable manner. A three-phase motor works by producing a rotating magnetic field generated by alternating three-phase currents, which spins the rotor inside it, thereby converting electrical energy into mechanical energy. Appropriateness of phase sequence guarantees stability and proper direction of the magnetic field so that the motor could start up smoothly and run in a stable way. When the sequence of phases is incorrect, the motor moves backward, and this directly influences the operating condition of the equipment and production efficiency.

When it comes to equipment with fans, pumps, and conveyors, reverse rotation may result in medium backflow or the turning over of a conveyor, which influences the production progress. Greater wear and tear on equipment and higher energy consumption result from this fact. From actual test data, it follows that phase sequence errors may increase the losses of the equipment by 20% to 30% compared to normal operation. In some systems with high requirements for control, the phase sequence error can also lead to an instantaneous motor overload, which will generate extra mechanical stress and further shorten the service life of the equipment.

Preventing Reverse Rotation

In industrial applications, motor reversal by phase sequence errors is a kind of common fault. On high-frequency-use equipment such as conveyor systems on production lines and liquid transfer pumps, motor reversal can lead to reverse product transfers or liquid backflow. On liquid transfer pump systems, not only does reverse flow damage the pump, but it also may cause abnormal pump chamber pressure, thereby creating a safety hazard.

The most straightforward method to avoid reversal will be to employ a phase sequence protector. The phase sequence protector is set up at the power input of the motor, from which it checks the real-time phase sequence to ensure correctness in the sequence taken for the connection in the motor. If there is some mistake in the phase sequence, then automatically it cuts off the power supply to prevent the motor from working on the wrong phase sequence. This protector works effectively in large-scale production environments to avoid reversal problems and maintain equipment in an optimum operating condition. A phase sequence protector also protects against faults due to incorrect phase sequence at restarts, especially on equipment with frequent start-ups.

Power Quality Impact

Power quality concerns the voltage, frequency, and waveform stability of electrical energy; phase sequence errors have a huge impact on power quality. A motor operating under the condition of incorrect phase sequence generates distortions in voltage and current waveforms and produces harmonic interference. The interference creates additional current losses within the motor, produces reactive power, and reduces overall system efficiency. Voltage imbalance within 2 to 3% leads to a motor-efficiency loss of about 5%, and voltage imbalance of 5% leads to a loss in efficiency up to 15% per data. Summed over long periods of operation, all these losses result in considerable energy waste and also accelerate the aging of equipment.

Phase-to-phase faults also result in voltage unbalance, which impacts both the startup and operational performance of the motor. Operating under unbalanced conditions results in increased load current of the motor, as well as the increase of the heat load on its winding, which could shorten the life of the motor. All this is a serious issue for big motors, as local insulation aging in the windings may occur, increasing the risk of failure. Therefore, correct phase sequence is important not only from a power quality perspective but also to extend motor life.

Protecting Equipment

Phase sequence protection is one of the major means of protection, especially for large equipment. A wrong phase sequence may lead to serious consequences, including damage to the equipment and stopping production lines. Additional load comes to mechanical parts such as gears and bearings when the three-phase motor rotates reversely, which speeds up the wearing of the equipment. For example, in compressors or refrigeration equipment, if the motor reverses, the flow direction of the refrigerant changes and hence has a direct impact on system pressure balance, leading to failure or even the destruction of the equipment.

Phase sequence errors lead to uneven winding loads, causing the motor to overheat. This cuts into its service life: every 10 degrees Celsius rise in motor temperature reduces the insulation life of the windings by half. Correct phase sequence reduces mechanical wear, keeps the internal motor temperature stable, and minimizes winding load imbalance; thus, guaranteeing the equipment operates steadily for a longer period. Therefore, phase sequence testing is one of the key measures in motor protection and directly influences equipment efficiency and economic value.

Phase Sequence Testing

These tests of phase sequence are important in establishing the correct wiring of the motor in a three-phase power system. Using a professional phase-sequence tester will help one to determine if the phase sequence is correct or otherwise in just a very short while, which during the installation of the motor or reconnecting of the same would be very important. Phase-sequence testers use a three-phase socket that can indicate the order of a sequence via LEDs or indicators to an operator who can easily make wiring adjustments.

Some modern industrial equipment comes equipped with automatic inbuilt phase sequence detection and protection, hence automatically conducting the test for an alarm prior to motor energization, to avoid safety hazards that may be caused by wiring errors. Those that have to be changed in position quite frequently would definitely require a phase sequence test after each reconnection to ensure smooth running. Besides, regular testing of phase sequence effectively avoids the faults of the equipment caused by wiring errors; thus, to ensure that the production line works under high efficiency and safety.

Common Issues

Phase-sequence errors represent one of the most common problems in three-phase motors. The kind of problem seriously influences normal equipment operation. The following are some of the common problems and solutions associated with phase sequence errors.

The most frequent consequences of such errors are motor failures. Due to the fact that motors rotate in reverse, the equipment operates in a non-design state, hurting production efficiency and product quality. On some precision-controlled processing equipment, phase sequence errors may further lead to more errors during the production process.

Other influences of phase sequence errors are anomalies in power consumption. The three-phase motor, when it has unbalanced phase sequence, will generate reactive power and losses that are ineffective, hence increasing consumption. On high-power equipment, reactive losses from phase sequence errors are from 5% to 15% of the overall energy consumed. With time going on, this unnecessary consumption increases, raising electricity costs and impacting economic efficiency.

Phase-to-phase sequence errors create safety for the equipment when critical equipment requires a certain rotation sequence. Phase-to-phase sequence errors result in additional mechanical stress that can lead to premature failure of some components. On big machines, such as conveyors or cooling towers, a reverse direction of rotation could mean a reverse flow of the respective medium and increase the possibility of damage to the given equipment.

Other common problems developed from phase sequence errors are overheating. The running of the motor with the wrong phase sequence was attributed to uneven winding load, heat build-up, and consequently resulted in the shortening of equipment life. Thus, management of phase sequence is quintessential as far as production efficiency is concerned and directly impacts maintenance cost and safety of the equipment.