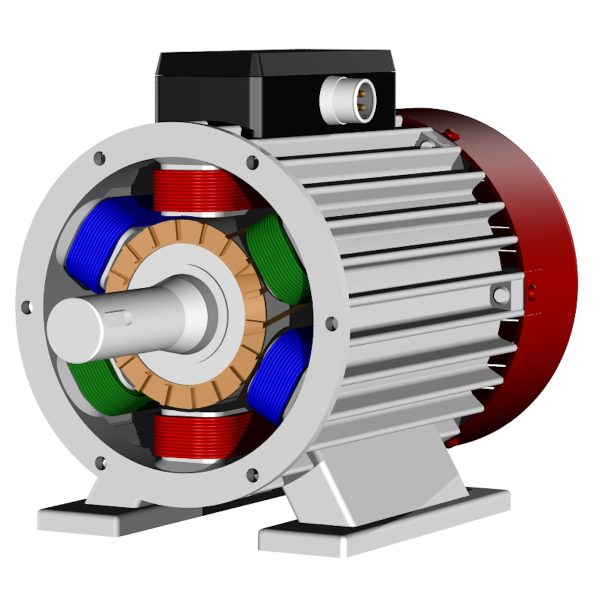

Common faults of three-phase motors are overload, aging of insulation, and inter-phase short circuits. Statistical data show that about 25% of the total faults are related to insulation. Regular insulation resistance testing, maintenance above 1 megohm, and quality insulating material can reduce the failure rate and extend the lifetime of a motor.

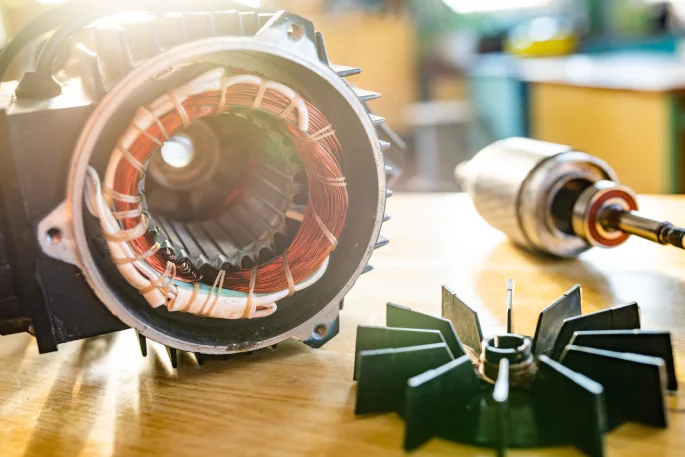

Inter-Phase Short Circuit

An inter-phase short circuit is one of the common faults in three-phase motors. This accounts for about 30% of motor failures. Shorts to the ground usually result from the aging process of insulation materials or damage during operation; their lifetime may vary between 5 and 15 years, depending strongly on the environmental conditions. The symptoms of a short circuit often consist of current imbalance; the current of one phase may rise above the rated value by more than 20%. This is done to reduce risk by routinely checking the insulation resistance value of the motor, at least 1 megohm.

The different ways to solve inter-phase short circuits include periodic checking of the motor’s wiring and insulation conditions. The investment in high-quality insulation materials according to the actual conditions can increase the life span of a motor while improving comprehensive efficiency. The application of high-performance insulating materials, such as polyester and epoxy resin, could effectively reduce the possibility of a short circuit. Sometimes, thermal imaging technology monitors the temperature distribution of a motor for maintenance teams so that any forthcoming fault can be spotted at an early stage. The effectiveness of such a device in fault detection can be as high as over 90%, with remarkably reduced maintenance downtime.

Motor Startup Difficulty

Operational starting-up difficulty is a frequently encountered phenomenon among the three-phase motors, and about 15% of the motor failures occur due to this. Such faults mostly occur when the motor has a higher power rating, especially when the load crosses the rated value, which eventually results in failure or delay in startup. This can be 6 to 8 times the rated value at startup and places higher demands on the power supply and control system of the motor. A large number of factors can make startup difficult: either due to insufficient supply voltage, loose connections, or faults internally within the motor itself. Accordingly, a 10% decrease in power supply voltage can result in a loss of about 20% with respect to the starting torque of the motor, and it thus seriously affects starting performance. Therefore, it is very important to ensure that the voltage supply keeps to the rated value.

Sometimes, the start failure of a motor can be traced back to overload protection devices set too low. Once this occurs, the set current in overload protection devices will be less than the actual current required at the time of starting up, and thus, the motor cannot start up normally. This requires special attention during the installation and debugging phase. Effective solutions to difficulties in motor startup include optimizing the motor control system and regularly checking the power supply voltage. Using variable frequency drives, in some cases, also effectively improves motor startup performance and allows the current at startup to remain below 150% of the rated value, hence reducing the impact on the power supply.

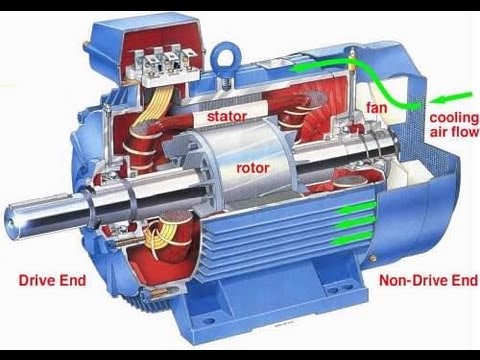

Motor Noise Issues

Noise in motors is always a problem in industrial production. More than 20% of motor failures are related to noise problems. Noise not only affects operating environments but may also indicate the presence of internal faults within the motor. According to some reports in the industry, during normal operation, the noise level for a motor should be controlled below 75 decibels; exceeding this standard will affect the efficiency and comfort of employee work. Noise is usually emitted from mechanical vibration, bearing wear, or imbalance in the fan blade. Bearing wear and tear can raise the noise level of any motor by more than 10 decibels, and this lessens the service life of the equipment if continuously operated.

Noise reduction will necessarily have to depend on routine checkups of the mechanical parts of the motor. The effective measures for treating motor noise problems involve adjustment of installation positions and improvement of sound insulation measures. Some firms have greatly reduced the level of noise by adding soundproof materials around the motor, which lowers noise from 85 decibels to 65 decibels, almost to a noiseless level. The use of higher-quality lubricants can effectively reduce friction and noise. High-quality lubricants can lower the operational noise of the motor by about 20%. Maintaining the balance and alignment of the motor will also greatly improve noise issues.

Insulation Aging

Insulation aging is a usual fault in three-phase motors. About 25% of motor failures are related to insulation aging. The service life of insulation materials is generally 5 to 10 years, and actual conditions may change because such environmental factors as temperature, humidity, and chemical corrosion can accelerate the aging process. After insulation aging, the insulation resistance value of the motor drops to 30% of its value in the original state.

Some of the techniques for solving the problems related to insulation aging involve routine testing of the insulation resistance of the motor. The minimum recommended value of insulation resistance is 1 megohm; if it is less than this value, repairs should be made without any further delay. Utilizing superior-quality insulating materials will also help to a great extent to increase the motor’s life. Superior-quality insulating materials can bear higher temperatures and strong corrosion, which can increase their life to more than 15 years, which is very vital to reducing failure rates. In practice, insulation materials can find some possible problems in advance by monitoring the motor temperature with thermal imaging technology.

Excessive Vibration

Vibration is one of the most serious and most common faults of three-phase motors. About 20% of problems in motors are caused by it. This fault will cause equipment instability; at the same time, it can also cause wear and tear in its parts, equipment aging, and an increase in maintenance cost. In industry, the limits for motor vibration are usually set below 2mm/s; if greater, this may trigger equipment failures.

It can be because of many reasons concerning unbalanced installation, bearing wear, or loose mechanical parts. When bearing wear reaches 5% of tolerance, the vibration level of the motor can increase by about 30%, potentially leading to more serious mechanical failures. Regular inspection of installation and alignment is all that is quite necessary for effective concern. Dynamic balancing technology can reduce vibration levels by 50%. Good connections and high-quality bearings, in particular, do much to improve vibration conditions. Motors fabricated with a better selection of materials tend to vibrate less—their lifespan is lengthened by more than 10% up to 20% or 30%.

Overheating

Overheating is one of the frequent faults of three-phase motors; an estimated 30% of motor failures are related to overheating. In general, within the rated temperatures, the temperature of motors should be maintained below 75 ℃ during operation. Higher temperatures will lead to a performance decline and equipment damage. It reduces the insulation life by half for every 10 ℃ rising in temperature. Normally, the industry will set up some temperature monitoring devices in order to monitor the running status of the motor in real time to ensure it works within a safe range.

Overheating may be due to overload, poor ventilation, or improper lubrication. If the load of the motor exceeds the rated value by 20%, the temperature may rise by 15 ℃; the aging of the equipment will be accelerated by long hours of overload operation. Companies can create improvements by reducing the temperature of overheating motors through better ventilation and improved cooling measures. Increasing the number of cooling fans can reduce the operating temperature of the motor by over 10℃, extending its service life. Regular quality and quantity checks of lubricating oil can reduce friction heat generation to a great extent. Besides, regular maintenance of the motor and accessory equipment and a good working environment will effectively avoid overheating problems.