For high-power demand applications, the three-phase power is cheap. Although installation may be costlier, it has more energy efficiency and thus cuts down electricity bills and maintenance costs. In fact, for heavy industrial or commercial purposes, three-phase power is ideally suited.

Cost Comparison

In developing the cost differences in three-phase and single-phase power systems, consideration is given to but not limited to aspects such as the system configuration, equipment requirements, and usage scenarios. Three-phase power systems usually suit high-power support requirements; their infrastructure is more complex in terms of power transmission, control systems, and supporting equipment compared to single-phase systems. The wiring layout of a three-phase system requires at least three live wires and one neutral wire, while for single-phase systems, it requires only one live wire and one neutral wire. This directly means that the initial wiring cost is higher in the case of three-phase systems.

Three-phase system equipment has a better power factor and is capable of converting the active electric power to useful work much more efficiently than single-phase systems, which have always relatively lower conversion efficiency. That means three-phase systems consume less energy for the same output power, saving much electricity over some period of time. In general, three-phase systems realize a conversion efficiency of 15% to 20% over single-phase systems, which can greatly reduce the operational costs of such systems for large industrial or commercial applications. For instance, a manufacturing plant that operates on a 24/7 basis may realize over 20% savings on electricity costs due to the efficiency of a three-phase system, which could amount to substantial savings.

From the point of view of installation cost, although most initial costs related to three-phase systems are higher, their overall cost, in the long run, tends to be lower compared to single-phase systems due to reduced power loss and higher efficiency of the equipment. In applications where large amounts of power are fed, a three-phase system can reduce the long-term costs of power consumption by minimizing energy losses during the transmission of power. Some research shows that, due to voltage fluctuations and loss of power, single-phase systems will need additional stabilizers and compensators to maintain voltage stability over long-distance transmission, thereby further increasing the cost of their usage. The three-phase system will have less energy loss with the increase of transmission distance; hence, it will cost comparatively lower. This fact is especially disadvantageous at long distances.

Energy Efficiency

Three-phase systems find wide application in industrial and commercial fields due to their high energy efficiency. The characteristics of the three-phase waveform can distribute the current load much more evenly, reducing power loss and equipment wear. During actual operation, the power factor of three-phase systems is generally higher, reaching as high as 0.85 to 0.95, which symbolizes less reactive power consumption. In contrast, single-phase systems have a relatively lower power factor; moreover, frequent current fluctuations are apt to occur when there is a large difference in load changes, which is sure to increase the power loss.

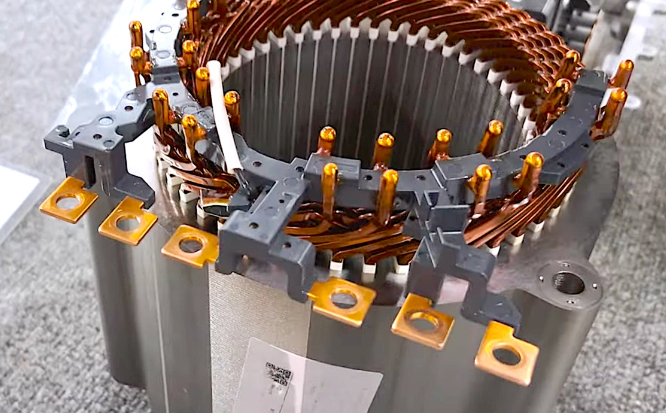

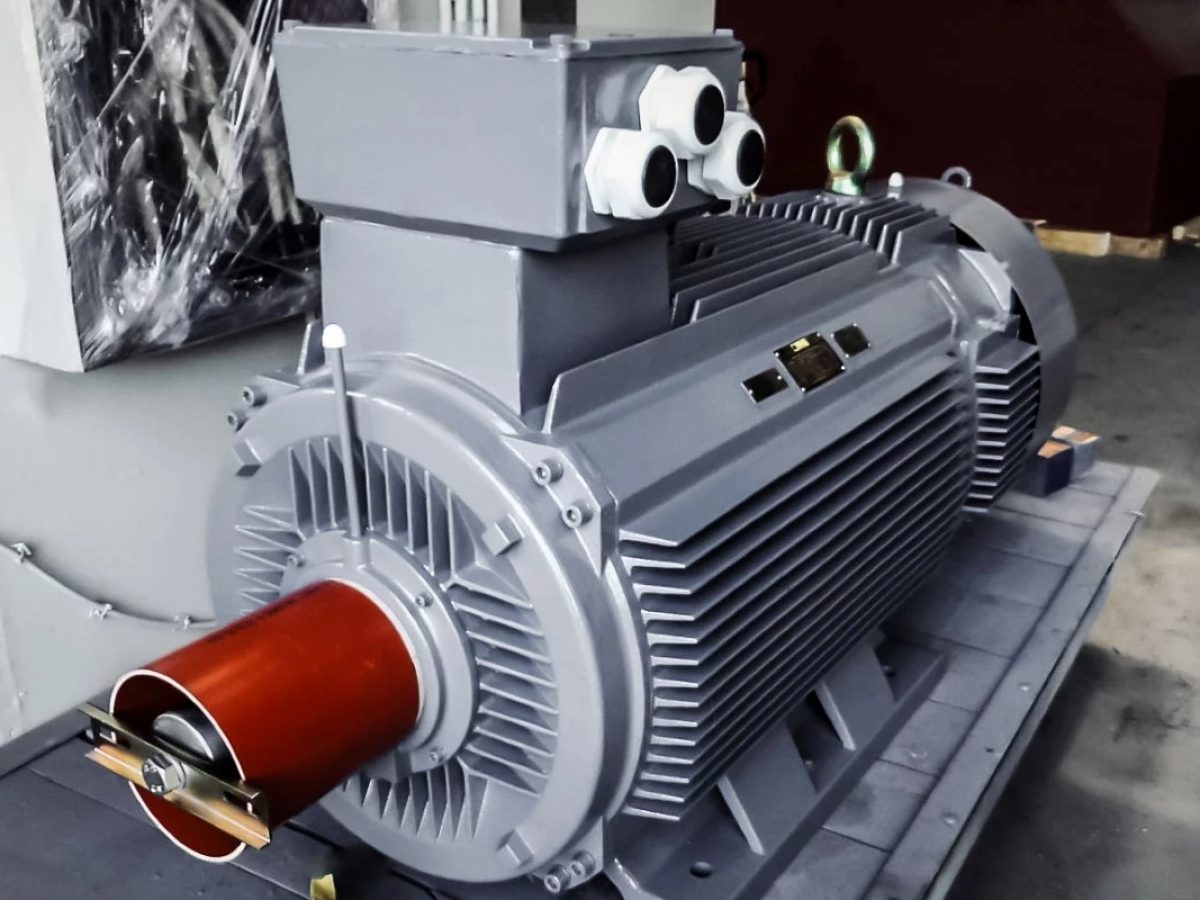

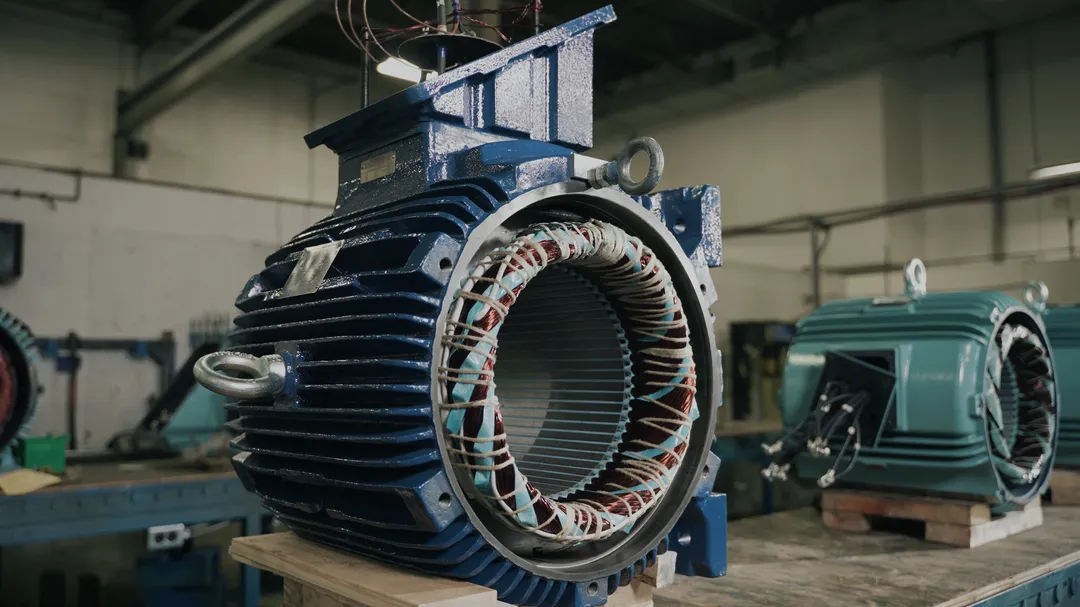

Three-phase systems can support high-load equipment operating stably, such as large motors, compressors, and transformers. In the equipment which is working under high loads, the first factor to be considered should be balanced currents, for long-time equipment life. It is easy to distribute the current in three-phase systems since it balances out against each other, avoiding single-phase systems defects such as overheating of cables and aging of insulation when heavy current flows, which can improve the durability of the equipment. In high power motors, three-phase can avoid windings overheating due to unbalanced current. The advantage is in the low number of repairs and substitutions of parts or equipment.

Three-phase power energy efficiency is very prominent in power transmission. It will reduce the power loss and increase the utilization rate of the whole grid for long-distance transmission. In three-phase systems, line losses are about 15% less than single-phase; thus, three-phase supply is usually used in industrial supplies. In a general industrial power supply system, three-phase systems have smaller voltage fluctuation. This may prevent the wear and impact that frequent voltage changes have on equipment and will improve the stability of the whole system.

Installation Cost

Installation cost is an important factor to take into consideration when choosing a power system. The installation cost of a three-phase power system mainly consists of the cost of equipment, cable wiring, and setting up the control system. The three-phase power will require three live wires in addition to one neutral wire; it tends to be more expensive on account of wiring material and engineering. To accommodate such high-power output, three-phase systems require meters, switches, and distribution panels of much higher specifications, which tend to be more expensive compared to those utilized for single-phase systems.

Although the three-phase installation is highly expensive, most of the commercial and industrial scenarios opt for three-phase systems because of their long-run economic advantage. It is said by engineering statistics that three-phase power installations cost about 10% to 30% higher than that of single-phase systems, while the energy efficiency advantage of three-phase systems often allows the additional installation costs to be recouped through savings in electricity and maintenance costs within 5 to 10 years.

The installing cost of the three-phase system can be influenced by the surroundings. The three-phase wiring can use a centralized power supply method for big-scale factories and multi-story buildings, which effectively reduces the amount of cable and equipment needs for distributed power supply, thus reducing installment costs. Many power companies encourage users to use more efficient three-phase systems by offering commercial customers incentives for three-phase power, such as installation subsidies to reduce the price of electricity. The incentives, to some degree, reduce the initial investment in three-phase systems.

Power Load

The demand for power load directly influences the appropriateness of the choice between three-phase and single-phase power. Three-phase systems have considerable merits in handling demands with high loads, especially in manufacturing, processing, and transportation, where three-phase systems can provide a stabilized power supply for high-power equipment. Large current surges are generated by motors at the time of startup and operation; through three-phase systems, balanced current distribution can reduce the impact of current fluctuations on the grid and equipment to ensure stability during equipment operation.

In industrial uses, a three-phase system not only can provide higher power but also reduces the current demand of the device due to the distribution of current, preventing overheating of cables and loss of power. For high-load factory equipment, this balanced current distribution reduces internal current imbalance wear within equipment, thus helping to extend the service life of equipment. In contrast, a single-phase system is normally enhanced with different stabilizers during high power load handling in order to prevent the occurrence of equipment damage and unbalances in currents that are more likely to create frequent fluctuations in current.

Three-phase systems achieve high-power load demands with enhancement of the power factor of the power system and reduction in reactive power waste. Industrial applications, in particular, increase consumptions of reactive power, not only increasing electricity consumption but also further affecting grid stability. The proportion of reactive power can be reduced in three-phase systems with a high factor of power, which may further improve the overall energy efficiency. The three-phase power can also provide higher current-carrying capacity for large machinery and equipment and help meet diverse needs. More broadly speaking, in automatic chains of production, the three-phase power can supply simultaneously more devices, which is more efficient for the whole system.

Maintenance Needs

Due to the stability in structure and rational design, three-phase systems require much less frequent maintenance compared to single-phase systems. Balanced current distribution of three-phase systems and high power factor help improve the effectiveness of power utilization and reduce wear and probability of failure during long-time operation. In threephase systems, cables, connectors, and transformers suffer from less wear; therefore, reducing their maintenance frequency and cost.

Three-phase systems require low maintenance since they have the capacity to tolerate the fluctuation of loads. Fluctuations in the load are one of the major reasons for power equipment failure. The fluctuating currents under substantial changes in the load accelerate equipment wear in single-phase systems. Since the three-phase systems operate on balanced three phases, the influence of such fluctuations can be reduced on the power system and equipment. Statistics show that every year, three-phase equipment is 20% to 30% cheaper to maintain than single-phase systems. In a nutshell, the advantages of three-phase systems are quite significant for high-load scenarios.

In such industries as petrochemicals and metallurgy, the interference resistance and high load capacity of the three-phase ensure equipment functions stably under extreme conditions. The respective industry’s requirement for high stability in the supply of power is also very high. Furthermore, low maintenance requirements indirectly contribute to lower corporate operation costs, since not only can the downtime be reduced but the workload of maintenance personnel is also lowered. Therefore, three-phase systems are often favored.

Usage Scenarios

As in the different application areas, there exist quite different requirements on the power system. With this regard, there is quite a big difference in the applicability of three-phase and single-phase systems. In residential, retail, and small office premises, single-phase power is generally sufficient for most power applications due to relatively low loads in these application areas. The single-phase power requirement will be enough for lighting, air conditioning, small appliances, and office equipment; therefore, it suffices for most households and small businesses since wiring and installation are cheaper.

Three-phase systems will be more suitable in industrial and large-scale commercial applications. Three-phase systems permit high-power equipment, such as heavy machinery, motors, and compressors, to work uninterruptedly. Three-phase systems are also implemented in modern manufacturing, considering the automated production lines, to allow the equipment to reduce the current load through balanced distribution; hence, increasing the life of the said equipment.

Three-phase power also offers long-term advantages in the field of sustainable power supply. Three-phase power could provide uninterruptible power for data centers, hospitals, laboratories, and other facilities with high demand, which can minimize system failures due to voltage fluctuations and increase efficiency and stability. Many commercial buildings and high-rise residencies are beginning to adapt to three-phase systems for the power demand for elevators, water pumps, and other large equipment.

Long-Term Savings

In long term, energy efficiency and lower maintenance cost benefits of three-phase systems can result in considerable economic savings for companies. Although the initial installation of the three-phase systems is costlier compared to the single-phase ones, their higher energy efficiency and fewer failure rates have the potentials to cut operation costs in the long run. For the industries with high-power consumption, the savings in electricity cost through the use of three-phase systems can go up to 15% and 20%, which will make the payback period of investment relatively short.

The power system shall be comprehensively selected based on the long-term economic benefits, among which equipment depreciation and changes in electricity cost are particularly important. Based on the advantages in energy efficiency and maintenance, three-phase power systems are capable of reducing the amount of money a company spends on powering and thus enabling companies to reach an optimal solution with regards to cost control in long-term operations.