The following are the various three-phase induction motor starting methods: Direct start; Star-delta start; Autotransformer start; Soft starter; And Variable Frequency Drive (VFD) control. A direct start technique is simple but it causes a high starting current; thus applicable only to small motors. Star-delta start connects the motor initially in star to minimize the currents at the starting and then changes over to delta for full voltage in medium power motors. Autotransformer start applies a high-power motor drive by bringing the voltage down using an autotransformer and then switching up to full voltage. Soft starters gradually step up voltage for a very smooth start and are ideal where a unit is started frequently. VFD control adjusts frequency and voltage for specific control and energy efficiency when there are demanding startup applications.

Table of Contents

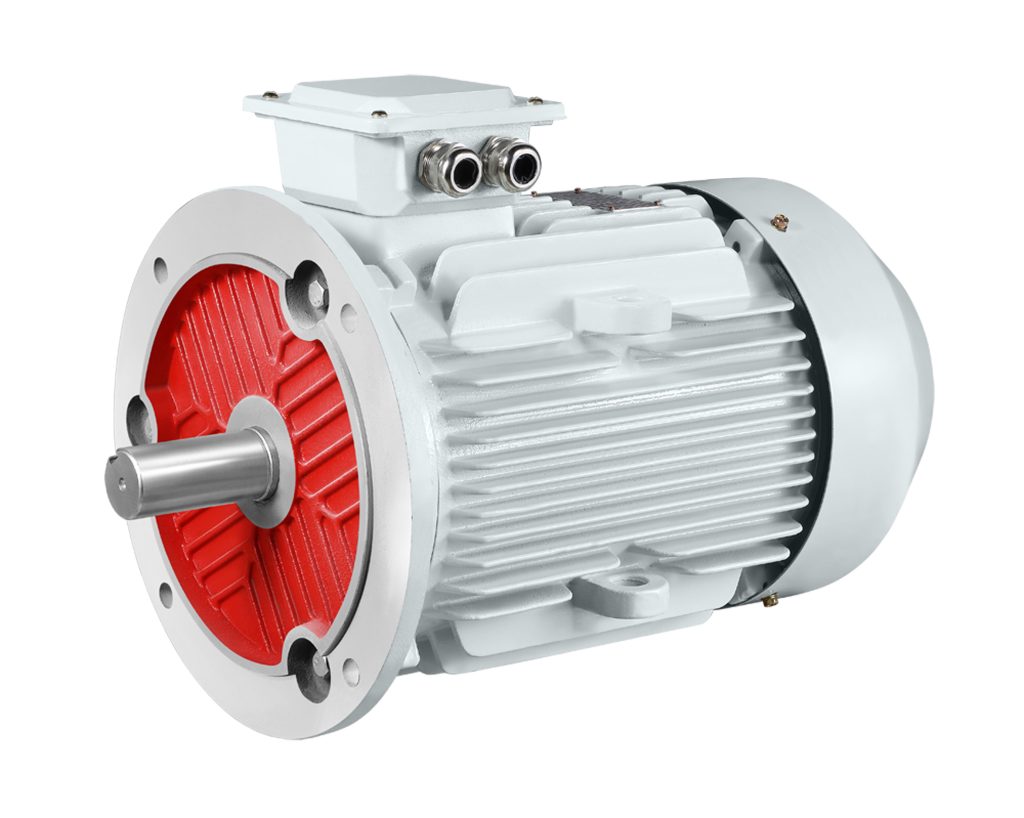

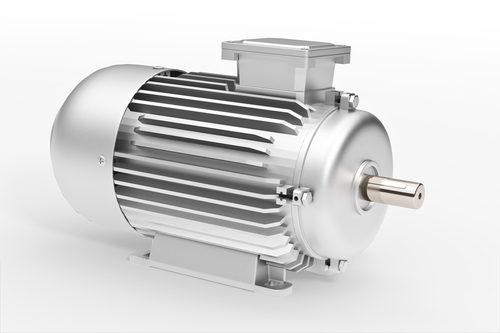

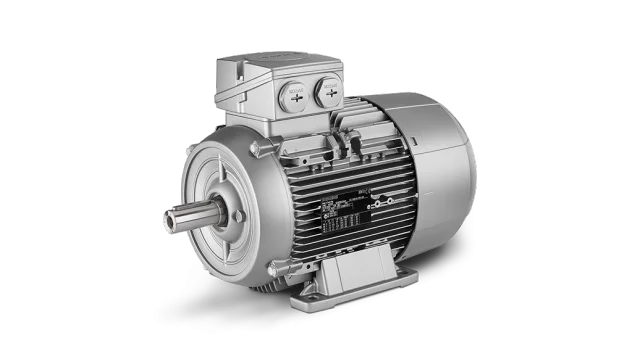

ToggleBasics of Motors

They are three-phase induction motors, which represent the most widely used type in industrial and residential applications due to its straightforward construction, operational stability, and negligible costs for maintenance. The working principle relies on electromagnetic induction; applying three-phase AC power to the stator windings generates a rotating magnetic field, rotating inside the stator, and interacts with the rotor, therefore making an induced current in the rotor, producing the electromagnetic force to drive rotor rotation. The rotational speed of the three-phase induction motor depends mainly on the power supply frequency and pole number, and the speed is typically varied by the power supply frequency and slip rate.

During start-up, the current is usually high. In most cases, it is 5-7 times the rated current. Such causes great stress on the motor itself and causes voltage fluctuations in the power supply system and other equipment. To minimize or reduce the initial current and protect the motor, various starting methods are applied to ensure a smooth start. Among them are direct starting, star-delta starting, autotransformer starting, soft starter, and VFD control, which are used according to specific circumstances or characteristics.

Direct Start

Direct starting is the simplest form of starting and can be applied to three-phase induction motors of low power. In the direct-starting method, the stator windings of the motor are connected directly to the supply voltage. Thus, the motor accelerates at a good rate to its rated speed. In this mode, the motor’s starting current is 5-7 times the rated current, and the starting torque is around 1.5 times the rated torque. Although big start-up influence is available, direct start appliances’ direct-starting equipment requirements are simple and inexpensive.

Direct start has only one advantage: it always promises to supply high starting torque. Hence, the facility of direct start is to be provided just for those applications where the required starting torque is high, while motor power is low. However, high inrush current causes many problems during direct starting of high-power motors, such as voltage fluctuations in the power grid network, which can cause other equipment on the network to experience a voltage drop and even cause brief power outages. Moreover, the thermal impact of high inrush current quickly builds up the temperature in the winding, significantly reducing the motor’s lifespan. Therefore, for the low-power motors especially those with low starting frequency and are less sensitive to grid power fluctuations, such as small fans and pumps, direct start is applied.

During operation, if the impact of the power grid caused by the direct start is too large, then proper adjustment of the startup time or the use of the grid supply system with greater capacity will reduce the impact during the current startup.

Star-Delta Start

Star-delta start is one of the widely used low-voltage starting techniques for three-phase induction motors. It is well-suited for medium-and small power motors. In this method, at starting end the motor stator windings are connected in star so that sum of currents drawn can be reduced to about one-third of the ratings and at some speed the connection switches over to delta for delivering full voltage to run. With a star connection, which reduces the stator voltage, the current is also reduced during starting, and a further benefit is that of effective reductions in the starting torque and its associated starting currents, though starting torque levels are usually about one-third of rated torque.

Advantages include being simple, not very expensive, and achieving effective current reduction at starting, which makes it suitable for applications where the load is relatively light during startup and torque requirements are low, such as fans and pumps with longer startup times and uniform loads.

Star-delta start does have several limitations. Current fluctuations significantly at the time of star to delta switching, leading very readily to current surges. This recent spurt can cause harm to the motor and equipment, especially if the load is variable or heavy. So, there is a need to ensure that the characteristics of the startup of the load are compatible for this method before this star-delta start is selected. Star-delta start is not suitable for motors having a high startup load like heavy-duty compressors or cranes due to lower starting torque.

Auto Transformer Start

The autotransformer start is a more complex method and is applied for a higher power motor. As this method reduces the stator voltage by an autotransformer, the starting current is decreased as well. In this method, the stator windings of a motor are connected to the power supply during its startup from the autotransformer. This reduces the motor’s voltage to 50% to 80% of the rated voltage through the tap position of the transformer. Therefore, after reaching some speed, the motor automatically changes over to full voltage operation, thereby achieving smooth motor startup.

The self-transformer starts with smooth starting conditions and minimal impact on current. The self-transformer can be designed for the variety of available start-up loads at multiple voltage levels and hence introduced through tap positions set at adjustable lengths. At optimal, the is generally 50% to 60% of full-voltage starting current and the torque is adjusted in such a way that significant starting torque is provided to satisfy the high-power equipment start-up requirements.

The disadvantages of autotransformer start are that the structure is relatively complex and hence expensive. This is used only for high-power motors requiring a high starting torque. Autotransformer start is widely used in high-power equipment like fans and compressors, especially where power supply quality is very important or the nature of load startup characteristics is particularly stringent. Autotransformer start minimizes impact on the power grid; hence, this too has advantages in situations where control over grid impact is required.

Soft Starter

A soft starter is an electronic device allowing motor smooth starts through gradual voltage increment with the application directly on the stator windings. Soft starters control voltage incrementally during startup, and motor current rises smoothly to control starting current with highly reduced impact on the power grid. The stability in soft starters is much higher than in star-delta and autotransformer starts and they have smooth adjustment at all stages of the startup process.

Soft starters allow setting acceleration time for completion of startup within a few seconds to tens of seconds with adjustable startup parameters based on load conditions. This particularly makes soft starters suitable for frequent startups such as pumps, fans, and compressors. The startup current of the motor can thus be reduced to 2-3 times the rated current under soft starter control and minimize impact on the grid. In addition, soft starters provide motor protection functions. These are about undervoltage, overvoltage, overcurrent, and phase-loss protections. So the motor will have a greater lifespan.

The foremost disadvantages of soft starters are costlier and sensitive to temperature and load changes, which are built using thyristor-based electronics. Therefore, they must be used with care in high-temperature and highly variable load applications. Soft starters are widely applied in applications requiring frequent start/stop cycles, such as water pump and fan systems that demand smooth startup. They are widely used in modern industry, especially for those applications that require strict specifications on the startup process.

VFD Control

VFD control is one of the latest methods for starting motors. VFDs enable an input voltage and frequency to be varied for smooth startup with the gradual increase of motor speed. The instant of VFD-controlled voltage and frequency at startup will not generate current surges since it controls the acceleration at that time. Acceleration time can be varied in a VFD, that is, acceleration may start from zero to rated speed smoothly. Apart from removing high starting currents, VFD ensures accurate speed control.

The other major benefit of VFD control is energy saving. Because motor speed varies with the load demand, the energy consumption in fans and pumps has been drastically reduced by the use of VFDs. Furthermore, VFDs are offered with overload protection, undervoltage protection, short circuit protection, and numerous other safety features that enhance the safety of operation in motors.

VFDs have been applied extremely widely in modern industry, especially in those cases where speed change must be frequently carried out and precision control shall be approached such as conveyor belts and elevators. The initial cost of VFDs is very high. However, considering energy efficiency, stability, and the superiority of startup control, they cannot be replaced with others in many applications. Gradually, the application areas of VFDs are extended to energy saving and intelligent control, and more industrial equipment adopt VFD technology to upgrade their efficiency of production and the target of energy saving.

Comparison & Tips

The choice of starting method for a three-phase induction motor depends upon the motor power, load characteristics, power grid conditions, and cost. Each starting method is suitable for various load characteristics and startup requirements. Direct start is simple and efficient for low-power equipment but has a high current at starting. Star-delta start is cheap but requires a lighter load, while an autotransformer is suited to high-power motors requiring smooth starts-up, though complex and costly. Soft starters provide smooth startups; ideal for high-frequency startups. VFDs are suited to energy-saving applications and will be a trend in future industrial control.

Practically, the right starting method has to be selected based on load conditions and number of startups to ensure that performance is optimal and equipment life is maximized. Use direct or star-delta start when the load is less demanding and lesser. Use autotransformer or soft starter in cases where loads are more demanding or more stringent startup impacts are required. VFD is preferred for frequent startups and speed control.