DC motors are better for precise control and high torque needs. For example, a 48V DC motor delivers 300 Nm torque, ideal for forklifts lifting 2,500 kg. They excel at speeds from 10-300 RPM, with smooth adjustments via simple controllers, unlike AC motors needing costly variable frequency drives for similar precision.

Comparison at a Glance

| Aspect | DC Motors | AC Motors |

|---|---|---|

| Cost | A 10-horsepower DC motor costs $1,000-$1,200. Additional controllers add $50-$200 per motor. | A 10-horsepower AC motor costs $500-$700. No extra controllers needed for basic setups. |

| Efficiency | Operates at 70%-80% efficiency under high-speed conditions. A 20-horsepower DC motor consumes 107 kW at 70% efficiency. | High efficiency (85%-95%) at full loads. A similar AC motor consumes 83 kW at 90% efficiency. |

| Torque | Offers high starting torque (200%-300% of rated torque). Example: A 5-horsepower DC motor delivers 300 Nm at startup. | Starting torque is lower (150%-200% of rated torque). Additional components like soft starters may be needed. |

| Maintenance | Requires regular maintenance, including brush replacements every 1,500-3,000 hours. Annual cost: $1,000-$5,000 per motor. | Minimal maintenance required; designed to operate for over 30,000 hours without significant servicing. |

| Applications | Best for robotics, electric vehicles, and cranes. Example: A DC motor precisely adjusts robotic arms at 10-300 RPM. | Ideal for HVAC, pumps, and industrial machinery. Example: A 50-horsepower AC motor efficiently powers conveyor belts. |

| Energy Costs | Higher at low efficiency. Annual electricity cost difference for 100-horsepower motors can exceed $20,000. | More energy-efficient, especially under continuous operations, saving $1,500 annually per motor in industrial setups. |

| Size & Weight | Compact for portable uses. Example: A 500-watt DC motor weighs 2 kg. | Larger and heavier. A 50-horsepower AC motor weighs over 300 kg, adding complexity in installations. |

| Control | Simple speed control via voltage adjustments. Ideal for applications requiring frequent changes in speed. | Requires variable frequency drives for precise speed control, adding $1,000-$1,500 per motor to the cost. |

Advantages of DC Motors

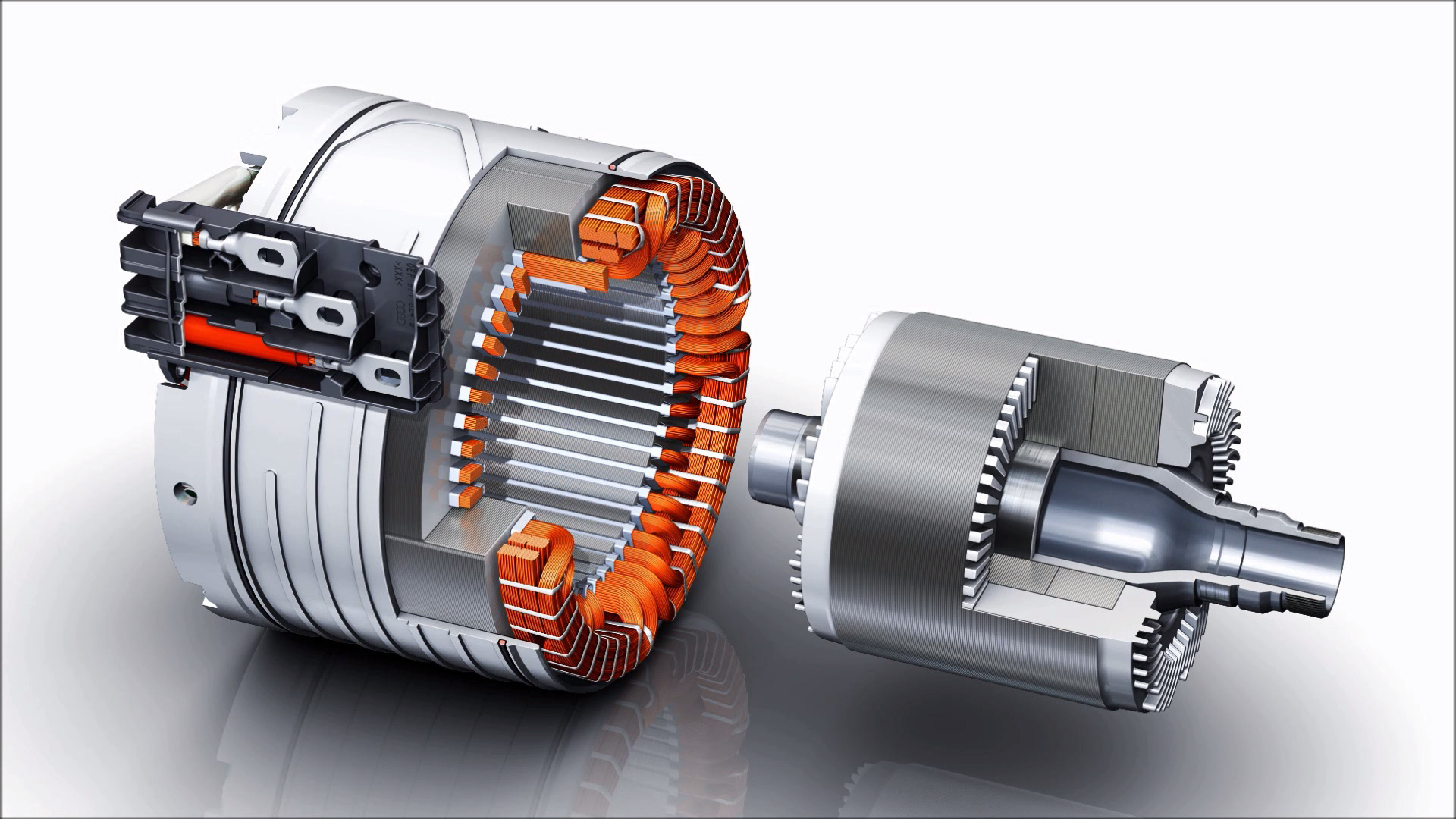

The general applicability of DC motors is highly valued for their precision control, high starting torque, and flexibility of operation. Indeed, their merits become most explicit when looking through their application in specific contexts supported by detailed data.

Among the important features of a DC motor is its speed control-an essential factor in industries manufacturing goods. For instance, in the conveyor belt systems of sorting facilities, a DC motor allows the operator to adjust the speeds from as low as 50 RPM to over 200 RPM with great precision. A 24V DC motor, running at 200 watts, will also easily work on a variable speed without overheating; whereas an AC motor would need additional variable frequency drives that increase the cost and complexity of the entire system. The consistent speed range of DC motors ensures minimal product handling errors, boosting productivity by up to 15% compared to systems relying on AC motors.

Another significant advantage of DC motors is their high starting torque, which is essential in applications like electric vehicles and lifting equipment. Take, for example, a 48V DC motor for an electric forklift that can give a starting torque of up to 350 Nm, allowing it to lift easily loads weighing as heavy as 2,500 kg. By comparison, an AC induction motor of similar size and power would only achieve perhaps a starting torque of 250 Nm without additional modifications, making DC motors the preferred choice in tasks demanding immediate power output.

They are also noted for compact designs that are quite useful in portable and space-limited applications. For example, a brushless DC with a rating of 500 watts can have a weight of as low as 2 kgs, hence highly suitable for electric scooters and drones. For instance, a scooter fitted with a 500-watt DC motor is able to ensure a top speed of about 25 mph with a lightweight frame, which is critical for urban commuters. AC motors with the same power rating come out much bulkier, where weight is not wanted, limiting its portability.

Disadvantages of DC Motors

Although DC motors have a good number of advantages, there is more than a fair share of drawbacks associated with their use. The disadvantages lie in areas of maintenance, cost implications, size, and efficiency of operation, among other factors, when put against AC designs.

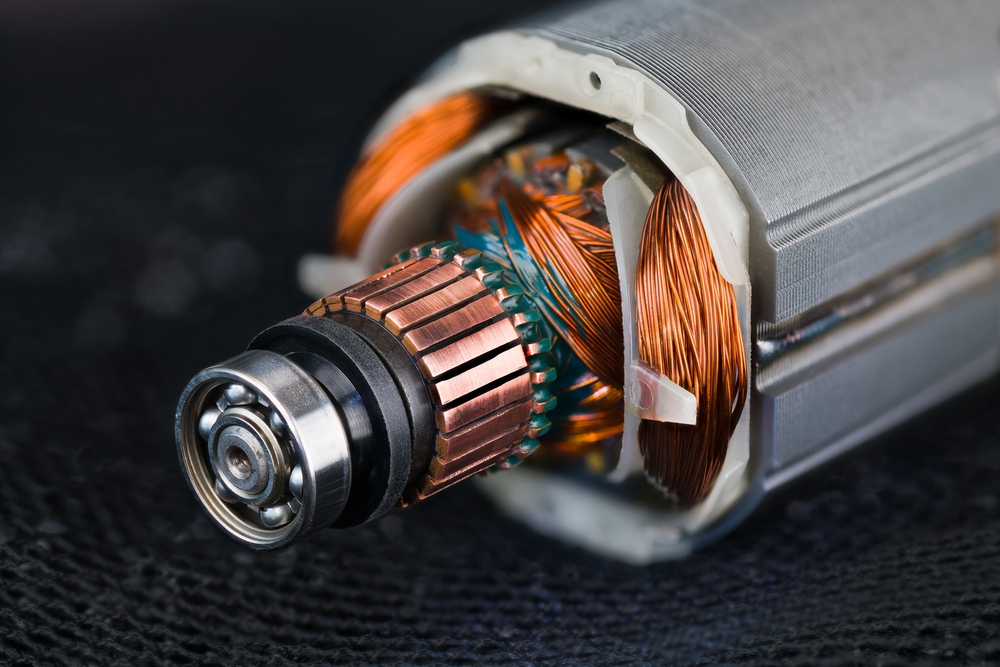

One of the major drawbacks of DC motors has to do with their maintenance need, especially for brushed designs. With long use, the friction between the brushes and commutator in brushed DC motors causes wear. For instance, depending on operating conditions and practice, similar brushed DC motors used in industries would need to replace brushes every 1,000 to 3,000 hours of operation. Therefore, losses developing from the maintenance time of such motors could result in extra operation costs that may be over $500 per annum in a medium-scale operation, considering labor and parts. Whereas this problem is offloaded by brushless DC motors, they require much higher upfront costs.

Another common factor which usually goes against DC motors is the cost. For example, a 500-watt DC motor would require around $200 to $300 in its purchase price, while the equivalent AC induction motor may be relatively inexpensive at $100 to $150. This starts to increase as it is scaled up for industrial applications. Also, the controllers required to have high-accuracy speed and torque regulation in DC systems can add between $50 and $200 per motor, making the investment far higher in total. In applications that are sensitive to budget, this higher cost makes DC motors less appealing.

The size and weight of DC motors, especially brushed ones, can also be a limitation in certain contexts. A 5-kilowatt brushed DC motor, commonly used in electric vehicles or industrial machinery, weighs over 50 kg and is less practical when compact designs are put into consideration. Similar power-rated AC with more optimized design may be up to 20% less in weight. This results in extra bulk, hindering those applications which need lightweight and portable solutions like drones or small robots, where literally every kilogram matters to assure good performance and efficiency.

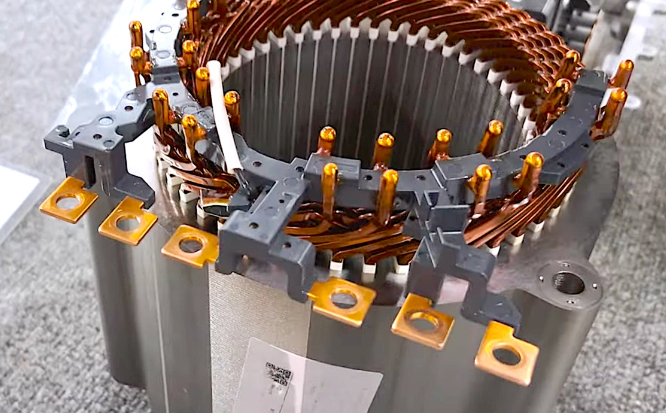

Advantages of AC Motors

AC motors boast of durability, cost-effectiveness, and adaptability for different power requirements, hence preferred in most industries. Their exclusive advantages are that they can be applied for large-scale operations and energy-saving systems with specific performance metrics and real-world applications.

One fundamental advantage offered by AC motors is their minimal maintenance requirement. In contrast to DC motors, AC motors do not generally have brushes, which involves periodic replacement. Whereas an industrial 3-phase induction motor may work for as many as 30,000 hours without any appreciable maintenance, saving $thousands per year in lost operation time and repair compared to a similar DC motor, which would replace brushes about every 1,500 to 3,000 hours with resulting unscheduled stops in operations.

Another critical advantage is that AC motors are more cost-efficient. As a fact, a 10-horsepower AC induction motor-a size commonly utilized for HVAC systems-costs about $500 to $700, whereas a similar-specification DC costs as high as $1,200, almost twice as much. Furthermore, the high operational efficiency of AC motors, easily topping above 85% in well-designed systems, saves electricity over longer terms. For instance, a factory using 50 such motors can save upwards of $10,000 annually in energy costs when compared to DC motors at 70% efficiency.

Another great thing about AC motors is that they are very resilient and can bear really harsh conditions. A 3-phase AC motor, which is applied to a conveyor system, may function well under dusty, humid, or high-temperature conditions without significant loss in its performance. These are designed to operate under extreme environmental conditions, with classes of insulation that enable operation at temperatures over 100°C. On the contrary, DC motors normally require extra cooling systems or protective enclosures, increasing both complexity and cost.

Disadvantages of AC Motors

AC motors, while widely used and efficient for many applications, also come with associated disadvantages in applying them to specific scenarios. This comes in the way of control complexity, high initial costs for an advanced setup, low starting torque, and constrained size in specific applications. All these factors, each differently, affect the choices of operation.

One of the major drawbacks of AC motors is the intricacy of their speed and torque control. Unlike DC motors, which can achieve easy speed variations by simply varying the input voltage, AC motors require VFDs for their precision control. A standard VFD for a 10-horsepower AC motor costs between $1,000 and $1,500, thus increasing the overall expense of the system. This becomes a critical factor in those industries that require frequent speed adjustments, such as manufacturing or conveyor systems, whereby DC motors very often provide a more economically viable solution for such precise operations.

AC motors also show lower starting torque compared to DC motors. For instance, in an induction motor, a 5-horsepower AC generally provides a starting torque that is 50% to 150% of its rated torque, depending on the design. In contrast, a similar DC motor can deliver starting torque of 200% to 300% of its rated capacity. This limitation makes AC motors unsuitable for applications like cranes, winches, or other heavy-load systems that require high initial power to overcome inertia. Quite often, using larger motors or an external mechanism is a way to offset this, at the cost of increased system size and cost.

Another drawback is the higher energy losses at lower speeds. Although AC motors are very efficient at full load, their efficiency may considerably decline when operating under partial loads or lower speeds. For instance, for a 20 horsepower AC motor operating at 50% load, losses in efficiency can go up to 15%. This inefficiency may account for an increase of over $2,000 in extra electricity per year for systems running continuously, especially in such energy-intensive sectors as the chemical or steel industries.

When to Choose DC Motors

DC motors are the motors of choice for applications that require precision in speed control, high starting torque, compact designs, and energy efficiency at variable speeds. Their distinctive capabilities further extend the range of applications to a variety of specialized uses, supported by practical data and real scenarios.

DC motors are suitable for applications involving precise and quick speed variations. In robotic systems used in manufacturing, DC motors can achieve precision level down to milliseconds for the movement. For example, the 24V brushed DC motor operating at 100 watts can actuate the robotic arm of an assembly line and provide adjustable rotational speeds ranging from 10 RPM to 300 RPM. This fine-tuning accuracy allows components to fall into their proper places with up to 20% fewer manufacturing errors. Most AC motors performing similar tasks need such functionality to be achieved with complex and expensive control systems, hence making DC motors cost-effective in such an environment.

High starting torque makes DC motors an excellent choice for heavy-load applications. In electric vehicles, a 48V DC motor that can supply up to 300 Nm of torque is able to accelerate a light car from 0 to 30 miles per hour in less than 4 seconds. It is this instant torque output that is important for city traffic conditions, where operation is under stop-and-go driving conditions. DC motors also find application in cranes and forklifts, as the motor’s ability to supply their rated torque while running at low speeds means quicker and gentler raising and lowering. In contrast, AC motors often require additional starting mechanisms, such as capacitors or soft starters, adding complexity and cost.

Compactness and portability further highlight the suitability of DC motors in portable devices and bounded spaces. A brushless DC motor, weighing just 2 kg, is capable of generating 500 watts of power and hence would be of prime application in drones, electric scooters, or medical equipment such as infusion pumps. These motors assure high performances without adding unnecessary bulk. For example, a scooter that has a 500-watt DC motor is capable of running at speeds of up to 25 miles per hour and cover more than 30 miles using a single charge. Comparatively powerful AC motors are always heavy and bulky, which restricts their use in portable designs.

When to Choose AC Motors

AC motors are the perfect fit for specific situations where longevity, economy, and high-power application effectiveness are in order. Their capability for large-scale operations and versatility in high-demanding environments has made them irreplaceable in a number of fields, based on certain quantifiable advantages.

AC motors find their very suitable applications in industries and other places where there is continuous demand for power supply with consistency and reliability. For instance, a 100-horsepower three-phase induction motor used in one plant can run without serious maintenance for well over 20,000 hours continuously. This, therefore, provides very convenient production cycles and cuts down on potential downtime costs. By contrast, DC motors of comparable power might require regular maintenance or brush replacements that disrupt operations and increase maintenance costs by more than $5,000 annually in large facilities.

Another reason for choosing an AC motor for high-power systems is cost efficiency. A 50-horsepower AC usually costs around $2,500, while a DC with the same power costs $4,000. Extrapolating this into larger plants requiring several dozen of these motors, the cost savings can reach upwards of $50,000 or more. Moreover, AC motors are also combined with variable frequency drives to lower energy consumption. For instance, an AC motor running at partial loads can save up to 30% in electricity costs annually, meaning industries related to chemical processing or even steel manufacturing are talking in terms of thousands of dollars while saving energy.

AC motors have specific advantages in extreme or challenging environmental conditions. A three-phase AC motor designed for mining operations would not see any performance degradation even in the most dusty, humid, or high-temperature conditions. Such insulation and protective coatings against hostile environments include temperatures well over 100°C. For instance, the ambient temperature in a mining operation could be as high as 50°C, for which an AC motor would be fully efficient, while the DC motor may have to use cooling systems, increasing not only the cost but also the complexity.