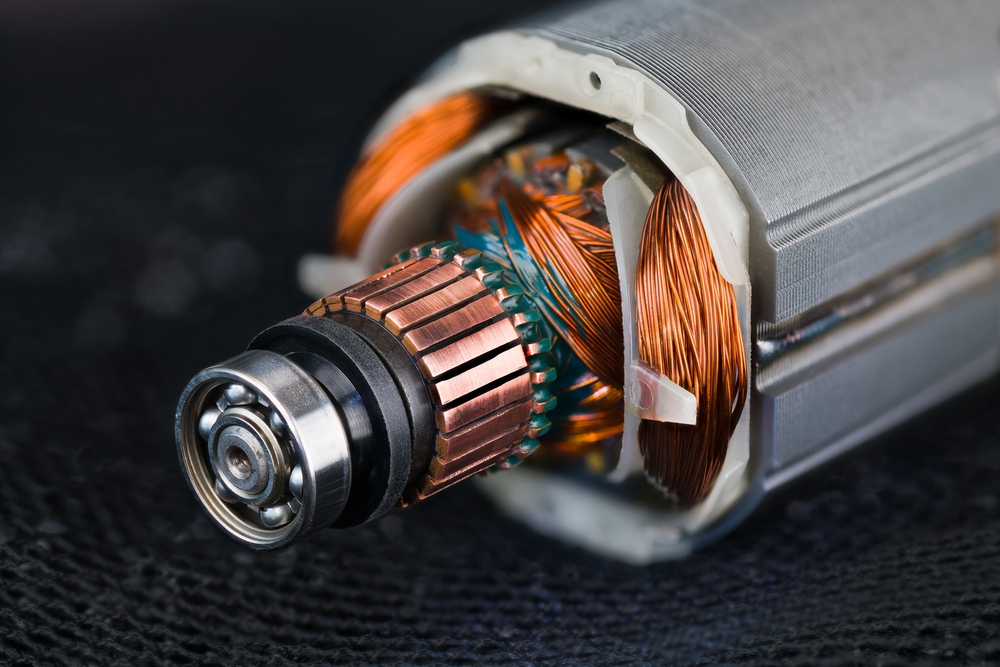

DC motors, known for their high efficiency, precise speed control, and high torque, are widely used in automotive, industrial machinery, consumer electronics, medical devices, aerospace, HVAC systems, and textile machinery. They provide reliable power and versatile solutions across various industries.

Table of Contents

ToggleAutomotive Applications

DC motors have heaps of applications in automobiles, except the windshields. Starting from window lifters, seat position adjustments, and moving toward the latest hybrid technology, DC motors have favored their efficient control of speed. In general, brushless DC motors in electric vehicles are prevalent due to their smooth torque output, very low energy consumption, and suitability for long-run usages. They are also very popular in fuel-powered vehicles for their dedicated tasks: purely auxiliary uses such as cooling and windshield wiper fans, which require smooth operation.

As DCs have become the last hope for offering comfort and intelligence in a modern vehicle, they will likely increase in importance. Small motors like these are used for controlling purposes in the case of electric trunk switches, power-folding mirrors, and seat massage functions. They all incorporate functionality in rapidly starting and stopping. Most luxurious vehicles now include brushless DC motors to enhance noise reduction and energy efficiency in place of traditional brushed ones.

In electric vehicles, DC motors not simply propel the vehicle’s main powertrain; rather, they contribute to energy recovery. The motion of the motor is reversed, changing kinetic to electric energy and storing it within the battery to increase the range of a vehicle significantly. This is achieved through the rapid response and high efficiency of a DC motor, both of which are used in this type of energy management technology.

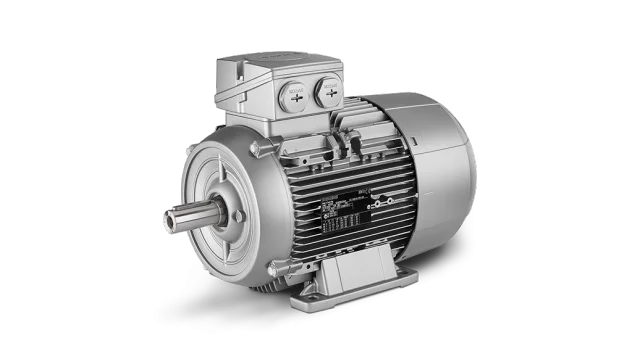

Industrial Machinery

In industrial machines, DC motors are used because they have great speed control and can deliver a high amount of torque. They are widely used in machines that operate with a very accurate control of speed, such as conveyor machines. Conveyors usually have to speed up or slow down many times in a process due to the abrupt changes in their working rhythm. This changeable speed regulation is possible using DC motors. At the end of the production line, DC motors will be installed in product sorting and assembling systems to make automated actions efficient and precise.

Industrial robots are part of today’s factories, and DC servo motors are the main part of their movements. From gripping to rotation through to linear movement, all are possible through servo motors working with sensors for precise action control. This gives a much more viable solution in comparison with AC motors because of the response time and actuation flexibility of DC servo motors.

Considerably high torque makes DC motors flawless for duty in starting machinery. The application of DC motors is now more common in cranes and mining machinery. The reason for their application is that most of the time, heavy construction machinery starts immediately from rest and requires high torque in a very short time, thus increasing the efficiency of equipment while reducing machine wear.

Consumer Electronics

Even consumer DC motors are very much part of the consumer electronics of nowadays. They are the electrical focus of most home appliances such as vacuum cleaners, juicers, and electric shavers. For power output in a lightweight build, there is no comparison with any other motor; things such as simple domestic goods can be designed using them within very limited constraints. In addition, they operate smoothly and produce less noise, contributing to a quieter and more comfortable home environment as far as appliances are concerned.

Smart appliances open an entirely new avenue for these small DC motors. Electric blinds, smart locks, and robotic vacuum cleaners use small motors for precise motion. Therefore, inbuilt brushless DC motors are fast becoming the norm in smart home devices as they spend relatively lower amounts of energy and have a longer wear and tear lifespan. In fact, they will be of greater concern to the consumer because the efficiency and durability of these motors are directly related to the satisfaction of the consumer as well as the lifespan of the appliance.

Gaming apparatus is also an extensive application area of DC motors. Vibration feedback in game controllers, for example, uses small DC motors. The response of the DC motors is a matter of time speed, whether accelerating in a racing game or the gun’s recoil in a shooting game.

Medical Equipment

In the case of medical equipment, precision and stability are very critical for the DC motors. These are used wholly by electric wheelchairs for smooth motion paired with very much precise speed and direction adjustment for safety and comfort for the user. DC motors are different from conventional types since they have high torque even at slow speeds, and this is required for a wheelchair to conquer slopes and obstacles.

With the existence of DC motors, the existence of surgical robots is possible today. Robots need movements with micro-level precision, demanding very high responsiveness and accuracy from DC servo motors. Another advantage of DC motors is the fact that they are quiet, hence providing a better working condition as far as other interfacing equipment and devices are concerned.

From the standpoint of an infusion pump or a ventilator as being life-supporting equipment, the reliability and energy efficiency of DC motors translate into improved operating performance and long battery life. Due to possible malfunctions, DC motors become preferable in the medical field due to the fact that they can be relied upon for high quality and low failure statistics.

Aerospace and Defense

Extremely reliable equipment is what the aerospace and defense sectors often demand to withstand harsh environments. Brushless DC motors are the main power source in drones, allowing for converting electrical energy to mechanical energy with good efficiency, as well as a long lifetime critical for long flying times.

Inside an aircraft, auxiliary components such as hydraulic control valves, electric doors, or landing gear operate using DC motors. DC motors reduce weight massively, increasing the energy efficiency and speed of the overall system over conventional hydraulic or pneumatic systems.

Defense applications have made heavy use of DC motors, e.g., missile guidance systems and military robots. Such systems require high durability and very precise motion control, which are aspects DC servo motors handle quite comfortably by achieving angle position changes with very low failure rates. Furthermore, DC motors produce a minimal noise level, making them more appropriate for stealth operations in a submarine or any other covert environment.

HVAC Systems

DC motors are the most efficient and energy savers in heating, ventilation, and air conditioning (HVAC) systems. Brushless DC motors are used to drive fans and compressors in modern central air conditioning systems. These motors provide consistent power output and speed control to follow temperature sensor feedback, which results in accurate temperature control.

Advantages of DC motors installed in residential and commercial ventilation systems are considerable. Fans with variable speed allow a user to set air supply according to requirements, while the low power consumption and high efficiency characterize DC motors as more economical in long-term use.

It is a low-speed operation that allows DC motors crucial roles for fresh air systems in maintaining continuous air distribution. In contrast to AC motors, DC motors offer greater stabilizing benefits and better energy efficiency at low speeds. Indoor ambience is also enhanced by a relatively quieter operation of the above.

Textile Machinery

DC motors are widely used in the capacity of speed control and precision in applications such as manufacturing processes in the textile sector. In weaving machines, the DC motors drive the mainspring shafts so it can be operated from a slow-speed start to high speed. The transition capability is essential to have maximum productivity and minimum material waste in textile production.

Other applications of DC motors in industry are found in sewing equipment. Modern industrial sewing machines have adopted DC servo motors for needle movements so that adjustments to the speed and output are stable while sewing complex stitching constructs. Flexibility in operation is vital where different forms of fabric materials come into play.

Other textile applications for DC motors include winding and dyeing machines. These types of machines need very accurate control over tension and speed, and DC motors are working with control systems to achieve fine operation versions for consistent product quality.