Three-phase motors are 10% to 15% more efficient compared to single-phase motors. The starting torque for three-phase motors is in the range of 150% to 200% of rated torque. Further, they provide smooth power with negligible vibration and noise levels that are 5 to 10 decibels lower. They are applicable when the power requirement is above 10,000 watts. The mean time to failure is over 40,000 hours for three-phase induction motors, and maintenance costs are lower.

Higher Operating Efficiency

Efficiency in three-phase motor operation is usually 10% to 15% better compared to single-phase motors because the three voltage phases of a three-phase power supply are out of phase from each other by 120 electrical degrees, hence they can create a constant and continuous rotating magnetic field that enables energy conversion in a much more uniform and efficient manner. While single-phase motors can only provide a pulsating magnetic field, not only do they have lower operating efficiency, but they also require additional starting devices, such as starting capacitors, and need to have auxiliary windings to keep their operation running, further increasing energy loss and mechanical wear.

According to the U.S. Department of Energy (DOE), a three-phase induction motor of 15 kilowatts can realize over 93% efficiency at standard load conditions, while for a single-phase motor of the same power, this normally lies between 80% and 85%. The apparent difference in efficiency not only reflects in energy consumption but also affects the overall economic performance of the equipment. In actual industrial applications, the use of a three-phase motor in place of a single-phase motor can save 1.2 kWh per hour. Electricity costs 0.6 yuan/kWh, and with 8,000 operating hours per year, this saves around 5,760 yuan in electricity charges for the company. The above energy-saving effect is very relevant to industrial equipment that operates for a long time and will also be very important for controlling enterprise energy costs.

Three-phase motors are more likely to meet the national first-level energy efficiency standards, which means that they will be more energy-efficient and environmentally friendly from the perspective of the whole world’s energy-saving and emission-reduction policies. By adopting three-phase motors, such companies will not only be able to save energy but probably get a bonus for energy saving, tax reduction, and other policy privileges, which is conducive to further cost reduction.

Superior Starting Performance

Three-phase motors have good performance at startup and can therefore allow direct startup; the starting torque is generally 150% to 200% of the rated torque. This makes three-phase motors better in heavy-load and frequent startup applications compared to single-phase motors. In comparison, single-phase motors are designed with a starting torque usually in the range of 50% to 75% of the rated torque. Thus, in heavy-load startups, this will result in longer startup times, low efficiency, or sometimes failure of startup. This is mainly because the mechanism of single-phase motors relies on a starting capacitor or starting winding at startup, which is quite poor in comparison with three-phase motors.

In industrial automation, during the production process, equipment like conveyors and elevators require frequent starts and stops. Three-phase motors guarantee startup under full load conditions with high-speed drive capability, therefore greatly improving production efficiency. Limited by the capability of startup, single-phase motors cannot achieve quick responses and thus affect the efficiency and rhythm of the entire production line.

Generally, in the case of three-phase motors, inrush current can be 4 to 7 times the rated current, while for single-phase motors, this starting current may go up to 6 to 8 times the rated current. The excessive starting current not only strongly influences the power grid, distorting the normal work of other devices, but it can increase the heat in the motor itself, thereby reducing its service life due to increased wear inside the motor. When considering high-power startups along with frequent starts, three-phase motors are undeniably preferred.

More Stable Power Output

Moreover, their power output is much more stable, while the vibration and noise during their operation are comparatively low compared to single-phase motors. This comes because three-phase power forms a symmetrical rotating magnetic field, so that the motor rotor is evenly stressed during operation, which greatly reduces mechanical vibration and electromagnetic noise. According to actual test data, three-phase motors are usually 5 to 10 decibels lower in vibration amplitude and noise level than single-phase motors, which is very important for some special application scenarios.

Vibration and noise have a big impact on the performance of equipment and the accuracy in precision machining. Precision CNC machine tools driven by a three-phase motor can provide, under ideal working conditions, machining accuracy as high as ±0.005 mm, which may not be possible when a single-phase motor is employed due to vibration and unstable power output. Besides, the steadier power output of three-phase motors can extend the service life of mechanical equipment and reduce wear and fatigue damage on mechanical parts under unstable forces, hence reducing the overall maintenance costs.

Stable power output also finds good application in areas where the demand for limited vibration and noise is high, such as high-end audio systems and medical devices. For example, in medical imaging equipment, the use of a three-phase motor can reduce operating noise, minimize interference that could occur as noise in the process of imaging, and improve clarity and accuracy in the images obtained.

Suitable for High Power Requirements

In general, single-phase motors do not have more than 10 kW of power; if higher, their efficiency and performance decrease significantly. Contrarily, three-phase motors have a broad range of power from several kW to several MW with good performance and high efficiency. For this reason, the three-phase motor has become the choice of solution for high-power applications.

In such heavy industries as the steel, chemical, and power industries, big equipment usually needs hundreds or even thousands of kilowatts of motor power. For example, a large compressor needs 500 kilowatts of motor power, which only three-phase motors are able to supply. Even under high-power loads, three-phase motors can ensure reliability and safety with respect to the stability of the operation process.

In the area of renewable energy, three-phase motors are used in wind turbines and hydropower generators. An upward limit of several megawatts is the power that these could generate; thus, they serve stable power into the power grid. Since three-phase motors have the capacity to handle larger power, their performance is excellent in many big-size equipment.

Lower Maintenance Costs

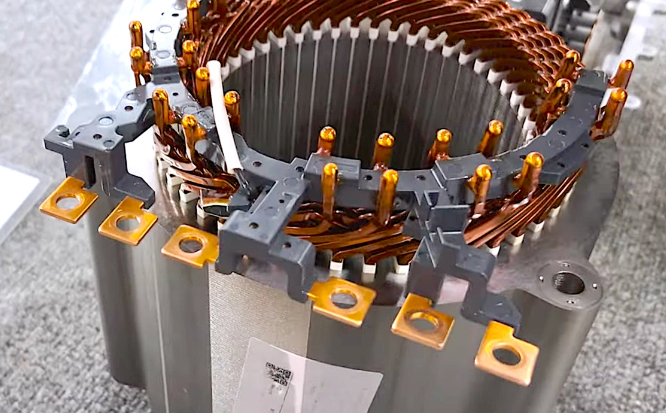

Their design is relatively simple, without complicated and sensitive parts such as starting capacitors or centrifugal switches, which results in a low failure rate and correspondingly long maintenance intervals. Statistics show that the MTBF for three-phase motors is over 40,000 hours, while the MTBF of single-phase motors is approximately 20,000 hours. Hence, this type of motor has a longer service life and consequently higher reliability during production.

Due to the high degree of standardization of three-phase motors, maintenance and repair are more convenient because many spare parts are mutually compatible. The common faults, such as bearing wear and winding short circuits, can be repaired by replacing standardized parts or rewinding coils. Single-phase motors have complicated internal structures and particular starting devices, making repair difficult sometimes, even requiring replacement of the whole machine.

For an enterprise, the equipment downtime resulting from motor failure affects production efficiency and economic benefit directly. Assuming that the failure of one motor results in the shutdown time of a production line being up to 1 hour and the production loss will reach tens of thousands of yuan. In this case, with an increase in reliability, three-phase motors minimize the rate of occurrence of equipment failure, shorten repair time, and increase availability and productivity.