Yes, a 3-phase motor can run on Delta or Wye depending on voltage. For example, a 230V/400V motor runs on Delta at 230V (full voltage per winding) or Wye at 400V (230V per winding).

Voltage Compatibility

Compatibility in voltage is the prime factor when selecting a three-phase motor for operation on either a Delta or Wye configuration. The choice has a direct impact on the performance, efficiency, and service life of the motor, as well as its safety. Understanding the relationship between the motor voltage ratings and the supply voltage is thus fundamental. A normal motor with 230/400V ratings operates on a Delta with a supply of 230V and on Wye with a supply of 400V. This makes the motor compatible with different power systems using a single design, making it even more versatile.

A 10 HP-rated motor, for instance, operates in Delta on a 230V supply and therefore sees the full line voltage on each winding. A motor of this character would have a current draw of possibly 28 amps per phase at normal operation. Conversely, if that very same motor is connected in Wye on a 400V supply, the voltage across each winding drops to approximately 230V-400V divided by the square root of 3. In such a way, the windings are not overstressed, and the motor runs optimally without overheating. That would equate to roughly 16 amps phase current on Wye for that same motor—a significant reduction from Delta and often a deciding factor when choosing a configuration for use in the field.

As an industrial example, consider a 50 HP motor driving a conveyor belt. The nameplate rating reads 460/800V. Because of this, in areas where the supply voltage is 460V, a motor should be connected in Delta to make use of the full voltage supplied efficiently. At 460V Delta, the current draw could be as high as 65 amps per phase. In areas with an 800V supply, though, a motor would have to be wired in Wye to make sure each winding deals with about 460V, while the current draw reduces to about 37 amps per phase. These differences show that the configuration should match the supply voltage to avoid damage and that the motor provides enough torque.

Voltage compatibility is also very important at the time of startup. Motors that start in Delta configuration experience very high inrush currents, usually 6–7 times the normal operating current. For a 30 HP motor in Delta on a 230V supply, the starting current might exceed 180 amps. This strains the electrical systems and heightens the cost of energy consumed. On the other hand, starting the same motor in Wye on 400V supply reduces the inrush current down to approximately 105 amperes. This huge reduction is not only useful for minimizing wear on electrical components, but it also avoids tripping protective devices, which makes Wye the preferred choice in cases that call for reduced inrush current.

Connection Method

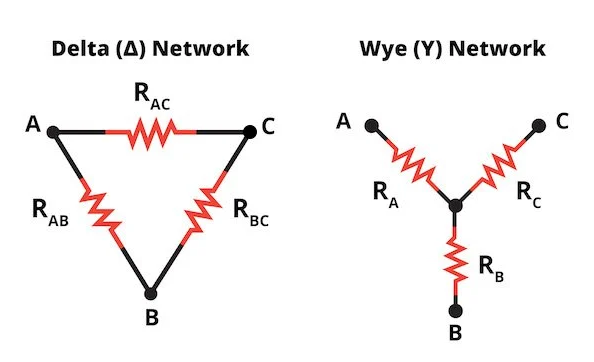

The windings of the Wye configuration are connected to a common neutral point forming a star shape. The voltage across each winding is reduced to 57.7% of the line voltage, as determined by the formula Vphase=Vline/√3. In a 400V supply, each winding in Wye receives roughly 230V. This lower voltage reduces starting current and torque and is preferred in applications requiring smooth startups, such as pumps or HVAC. Whereas in normal operation, the same 5 HP running Wye at 400V uses only 15 amps against 26 amps in Delta, therefore, Wye is more energy-efficient when in continuous service.

Another important aspect that must be considered involves the influence of the connection method on the heat generation inside the motor and its energy efficiency. A 20 HP motor running in Delta at 230V can result in severe heating because of a higher flow of current, as thermal losses are proportional to the square of the current. When the same motor is Wye-connected at 400V, the current is reduced, which reduces the heat generation inside it, thus improving thermal management. For example, when running at a moderate load, a motor would dissipate 800 watts as heat in Delta, whereas in Wye, it would lose only 500 watts. As such, it provides better energy efficiency and decreases maintenance burdens.

Torque Characteristics

The torque characteristics of a three-phase motor are directly affected by its connection method. It is very important to understand the differences in order to choose the appropriate configuration for a particular application. Under Delta connection, the full line voltage is applied to each winding, which generates higher starting torque. A 10 HP motor running on a Delta connection at 230V supply will have a starting torque of approximately 220 Nm. This high torque is beneficial for applications such as compressors or crushers, where heavy loads need to be overcome at startup.

In Wye configuration, the voltage across each winding is reduced to 57.7% of the line voltage, leading to a lower starting torque. A similar 10 HP motor operating in Wye at 400V would produce a starting torque of only about 125 Nm. Although this may not be good enough in heavy-load applications, it is a perfect solution for systems whose requirements are smooth acceleration and low mechanical stress—for example, centrifugal pumps or fans. The lower torque prevents shocking the connected load and helps to prolong the working life of equipment.

The torque-speed curve of a motor also changes with a different connection method. In Delta configuration, the motor typically provides higher torque through its operating range and is better suited for applications requiring constant high power, like conveyors or hoists. For example, a 15 kW motor in Delta at 230V may provide a full load torque of 650 Nm. Contrasting this, when this very same motor is connected in Wye at 400V, the torque falls to approximately 380 Nm at full load. This difference is huge for applications where high levels of torque need to be maintained over changing loads.

The other important aspect is how the connection method affects the starting current and torque ratio. Motors started in Delta can realize a starting torque equal to their full-load torque, drawing 6-7 times more current than the normal operating current. The same 20 HP motor in Delta might draw 120 amps at startup, which is enough torque to raise a loaded conveyor belt. If that same motor were started in Wye, it would draw only 70 amps and deliver about 40-50% of full-load torque. This lower torque prevents the motor from starting heavy machinery, which can be a disadvantage. However, this is an advantage in reducing strain on the electrical system and avoiding voltage drops in sensitive areas.

Energy Efficiency

In determining whether a three-phase motor should operate on Delta or Wye configurations, energy efficiency is always considered. This is because the configuration determines how the motor draws upon voltage and current and has a direct impact on power consumption and operating cost. In the Wye configuration, each winding sees a reduced voltage of 57.7% of the line voltage, hence drawing less current. For example, a 10 HP motor connected in Wye at 400V draws about 13 amps under a typical operation, translating to about 9.0 kW of power consumption. The same motor connected in Delta at 230V, running at full load, would draw closer to 22 amps and consume around 9.3 kW. Over extended periods, Wye can save energy, especially on continuous applications with the motor under a moderate load.

Another aspect of energy efficiency is the different thermal losses between the two configurations. Thermal losses are proportional to the square of the current; in Delta, where the current is higher, these losses are considerably greater. On a 20 HP motor operating at 230V Delta, for instance, the windings may see losses of about 1.5 kW due to resistance. When the same motor operates in Wye at 400V, the current is reduced, lowering the thermal losses to around 0.9 kW. This reduction not only improves energy efficiency but also minimizes heat generation, which helps extend the motor’s lifespan and reduce cooling requirements.

Startup energy consumption also varies between the two configurations. The general characteristics of motors in Delta are that it takes approximately 6-7 times the full-load current to start, thus creating a temporary demand on power. A 30 kW motor may have an inrush current of 180 amps in Delta and momentarily draw up to 35 kW of power at start-up. The inrush current in Wye is approximately 110 amps, due to lower voltage across the windings, and has a start-up power demand of approximately 22 kW. This makes Wye the configuration of choice in systems where reduction of peak power demand is critical in order to avoid overloading the supply or tripping protective devices.

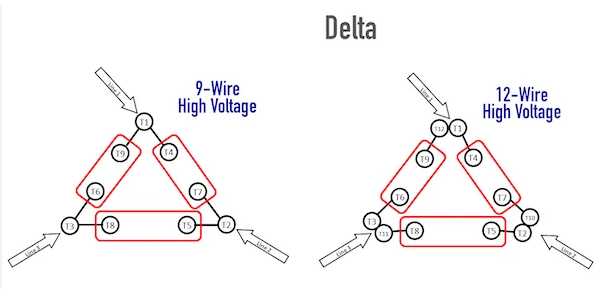

Dual Voltage Operation

In dual voltage operation, three-phase motors efficiently operate at two different levels of supply voltages, depending upon the configuration: either Delta or Wye. This is very important in applications where the power systems may change, such as in international operations or installations in countries with different voltage standards. For example, a motor rated 230V/400V would run on a 230V supply in Delta configuration and on a 400V supply in Wye configuration. For example, a 5 HP motor at 230V in Delta typically draws about 14 amps during full-load operation, whereas at 400V in Wye, it draws only about 8 amps, despite delivering the same mechanical output.

One advantage of dual voltage operation is the adaptability it provides for industrial applications. Consider a factory running a 15 kW motor designed for dual voltage operation. If this factory’s power supply is upgraded from 230 V to 400 V, the motor can easily be reconfigured from Delta to Wye without needing to replace. At 400 V in Wye, current would fall from 43 A in Delta at 230 V to approximately 25 A. This reduction not only saves operating costs by reducing power losses but also permits smaller and less expensive cabling and circuit protection devices.

Startup requirements also illustrate the benefits of dual voltage operation. Motors have a severe surge in current at startup, and dual voltage operation may help to alleviate these demands when needed. A 10 HP motor DOL started in a Delta connection on a 230V supply could draw an inrush current of 70 amperes at startup. The same motor, if started in a Wye connection on 400V supply, draws an inrush current of approximately 40 amperes, which is quite substantial. This reduced demand will prevent the overloading of electrical systems and ensure smooth operation in the facilities where many motors are to be started simultaneously.

Another factor that promotes energy efficiency for the life of the motor is the ability to operate in Delta or Wye configurations. For instance, during light-duty applications where the motor does not need the maximum torque to function, it could run a 20 HP motor in Wye at 400V, which saves up to 10% in energy costs compared to running the said motor in Delta at 230V. Assuming 8 hours of operation daily, this may translate into savings of around $1,460 per motor in a year at an energy cost of $0.10 per kWh. These savings really add up when multiple motors are in use, making dual voltage operation more and more essential to keep in mind in such energy-sensitive fields.

Star-Delta Starter

The Star-Delta starter is an extensively used method for starting three-phase motors, especially in industrial applications where reduced starting current and smooth operation of the motor are required. It works on the principle that during starting, the motor connections are made in Wye or Star to reduce the voltage and current across each winding. When the motor picks up speed and attains almost 70-80% of its full speed, the connection automatically switches over to Delta to enable operation at full power. For example, a 15 kW motor started in Wye might draw an initial inrush current of 30 amps, whereas if it is started directly in Delta, the inrush may reach 90 amps. This tremendous reduction in starting current reduces stress on the electrical supply system and voltage drops.

One of the main advantages of the Star-Delta starter is the smaller inrush current when the motor is started. A 30 kW motor, for example, connected direct in Delta at starting current could be as high as 200 amps, providing a surge that perhaps trips circuit breakers or disrupts other equipment connected to the same power supply. Using the Star-Delta starter, the initial current is reduced to about one-third of the Delta value or approximately 67 amps, depending on the motor specifications. This makes the Star-Delta starter ideal for those facilities that have limited electric capacity or where several motors are in operation at the same time.

This method also favors the torque characteristics of the motor. In star configuration, the starting torque is reduced to about one-third of what it would have been in Delta. That means for a 50 HP motor, in Delta the starting torque may reach 600 Nm, whereas in Wye, this would be closer to 200 Nm. While this reduction does mark the unsuitability of Star-Delta starters for high initial torque requirements such as in the cases of crushers or extruders, they work perfectly for pumps, fans, and conveyors where the load increases gradually. The smooth torque transition reduces mechanical stress on both the motor and the driven equipment, which enhances system longevity.

Energy efficiency is another point where Star-Delta starters can provide benefits. By reducing starting current and torque, the system reduces power consumption during its startup phase. Accumulated energy savings from using a Star-Delta starter for a motor running eight hours per day, starting five times a shift, add up. For instance, a 20 HP motor that consumes 10% less power in each startup would save around 250 kWh annually, assuming an average starting duration of 10 seconds. Given an electricity cost of $0.12/kWh, this would be $30 of yearly savings per motor, or significantly more for plants operating a number of motors.

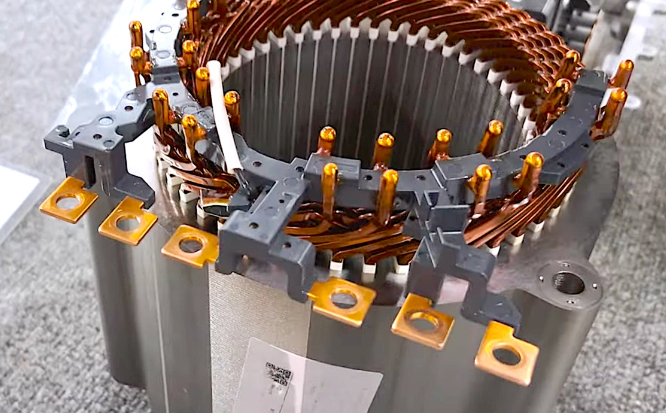

Motor Winding Insulation

The insulation of motor windings is one of the most critical factors that affect the performance, efficiency, and life span of a three-phase motor. These insulations protect the windings from electrical, thermal, and mechanical stresses. For example, a motor rated for 400V with Class B insulation can only stand a temperature rise of 80°C maximum, while a motor with Class F insulation can support up to 105°C. This difference allows motors with higher-grade insulation to do better in highly demanding applications or in unforgiving environments.

The choice of insulation directly impacts the voltage limits of the motor. In a Wye configuration, where the voltage across each winding decreases to 57.7% of the line voltage, the insulation is less stressed. For instance, on a 400V system, windings in Wye see roughly 230V, which is well within most standard insulation materials’ tolerance. Oppositely, in Delta arrangement, the windings experience the full line voltage, approximately 400V. The motors with low-grade insulation, for example, Class A with only a maximum temperature rise of 60°C, may deteriorate faster under such circumstances, which would increase maintenance costs and downtime for such motors.

Thermal stress is another factor heavily influenced by insulation quality. A 15 kW motor operating continuously at 80% load in an ambient temperature of 40°C generates heat due to current flow and losses in the windings. If the motor uses Class B insulation, the total temperature rise might approach the material’s limit, especially during peak loads. By contrast, motors with Class F insulation—which can operate as high as 155°C—offer a much larger safety margin. Especially critical in applications like compressors or sawmills where load surges often occur, a motor that is not adequately insulated may fail prematurely and cost upwards of $2,000 to replace.

Insulation also defines the resistance of the motor to the surrounding environment, including moisture, dust, and chemical exposure. Motors of varnished or epoxy-coated windings are better fitted for high humidity or corrosively active environments. For instance, a 10 HP motor operating in a chemical plant may need insulation to have less than 0.5% moisture absorption to avoid operational short circuits or dielectric breakdowns. Over a period of five years, a superior insulated motor may yield savings of $1,000 or more in reduced maintenance and repair costs when compared with a standard motor operating under identical conditions.