When it comes to three-phase motors, you’ll likely run into issues during daily use, like overload, phase loss, bearing problems, or even stator winding short circuits. In fact, most of the faults are focused on overload and poor heat dissipation, which accounts for around 70%. Don’t worry, though, these problems aren’t hard to fix as long as you know how to prevent and address them. Let’s go over some of the common fault signs and how to handle them.

Overload Leading to Motor Overheating

Symptoms: The motor’s outer casing gets hot, there may even be a strange smell, running time shortens, and efficiency decreases.

Possible Causes: Motor overload is a pretty common issue, and it could be due to excessive load, low power supply voltage, or poor heat dissipation. If this continues, the internal temperature of the motor will rise, the insulation layer will get damaged, and in severe cases, the winding may burn out.

Solutions:

- Check the motor load to make sure it’s operating within the normal range and isn’t overloaded.

- Measure the power supply voltage, keeping it in the correct range to avoid low voltage issues.

- Clean the cooling system, making sure dust isn’t clogging the radiator.

Motor Running with Phase Loss

Symptoms: The motor has trouble starting, makes strange noises, vibrates more, and has a higher current.

Possible Causes: Three-phase motors are especially prone to phase loss, especially when connections are loose or wires break. If one phase is lost, the motor has to run on just two phases, which can quickly lead to current imbalance and faster motor damage.

Solutions:

- Check the power connections to make sure nothing is loose or broken.

- Install a phase loss protection device to automatically cut off power and protect the motor when a phase is lost.

- Regularly check cables and replace any aging or damaged ones promptly.

Bearing Issues Causing Noise and Vibration

Symptoms: The motor makes a lot of noise while running, vibrates severely, the temperature rises, and the current fluctuates.

Possible Causes: After long-term use, if the bearings don’t have enough lubrication or debris gets in, they’ll wear down, causing noise and vibration. In severe cases, the rotor may become misaligned, which will make things even worse.

Solutions:

- Regularly inspect and replace bearings, ensuring there’s enough clean lubrication.

- Use high-quality lubrication oil to prevent premature bearing wear.

- Ensure stable motor installation to prevent rotor misalignment.

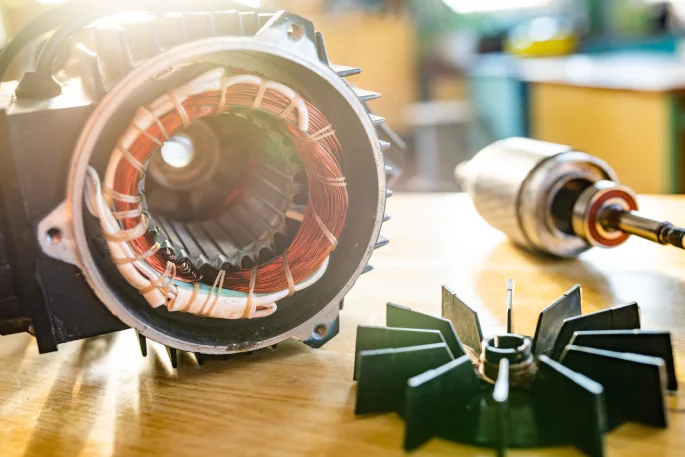

Stator Winding Short Circuit or Open Circuit

Symptoms: The motor can’t start normally, the power drops significantly while running, the current fluctuates greatly, and sometimes the fuses blow.

Possible Causes: Winding short circuits or open circuits usually happen because of insulation aging, overheating, or mechanical damage, and this is one of the main causes of motor failure.

Solutions:

- Test the winding with an insulation resistance meter to ensure proper insulation performance.

- Avoid long-term overload operation to prevent winding overheating and damage.

- Regularly inspect and maintain windings to prevent mechanical damage.

Mechanical Faults Caused by Rotor Imbalance

Symptoms: The motor vibrates abnormally during operation, the sound is uneven, and it affects the stability of the equipment.

Possible Causes: Rotor imbalance is usually caused by wear, deformation, or insufficient manufacturing precision, and over time, rotor imbalance can lead to mechanical faults in the equipment.

Solutions:

- Perform dynamic balance testing on the rotor to ensure it runs smoothly.

- Replace or repair severely worn rotor components.

- Regularly inspect the rotor to prevent large imbalances during operation.