According to relevant research, there are several major determining factors in the service life of a three-phase motor: temperature, mechanical stress, electrical stress, frequent starts and stops, and environmental factors. It is observed that with every 10℃ rise in temperature, the insulation life of the motor decreases by 50%. Regular maintenance of the cooling system, balancing the load, and avoiding overload operation can prolong its use.

Temperature

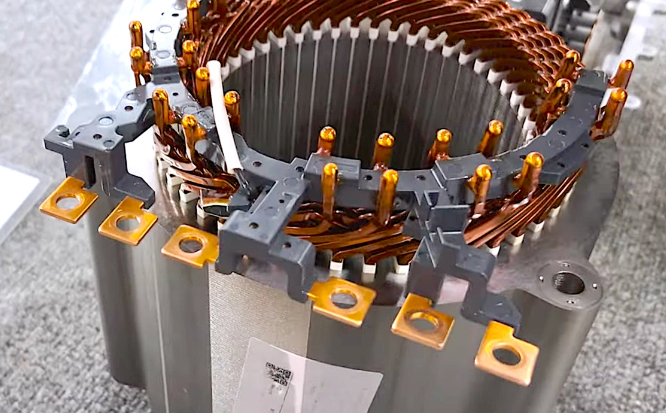

Temperature has a great influence on the service life of a three-phase motor. High temperature can lead to an accelerated aging process of the motor insulation materials, which in turn can shorten the service life of the motor. Usually, the windings in the stator and rotor inside a motor are wound with insulation materials, which may be classified based on various grades regarding allowable resistance to heat. For instance, class H insulation materials can withstand operating temperatures up to 180℃.

However, even so, the insulation materials are highly affected in terms of their service life once the temperature increases. As the law of thermal aging goes, with each additional 10℃, the aging rate of the insulation materials doubles. Assuming that a certain motor operates at 80℃ for 100,000 hours, or about 11 years, during application, if the temperature goes up to 90℃, its lifespan may shorten to 50,000 hours, or about 5 years.

Temperature regulation usually depends on the design of the motor cooling system and the conditions of external heat dissipation. Most industrial motors are designed with external cooling fans or installed in systems with circulating coolant.

When the cooling fan efficiency decreases by 50%, the temperature of the motor windings may rise to 1.5 times the normal value. Keeping the cooling system working normally and keeping the cooling channels clean are just some of the basic tasks that can be done to extend the service life of a three-phase motor.

Cooling fans, heat sinks, and internal ventilation ducts should be periodically cleaned and checked, especially when operating in dusty or high-temperature environments.

Mechanical Stress

A three-phase motor may undergo several forms of mechanical stresses during operation. These stresses arise from internal rotational movements, fluctuations in loads externally, and from mechanical impacts. The consequences of mechanical stress include bearing wear, vibrations, and other mechanical failures that influence motor lifetime.

Of all the motor components, bearings are the most prone to failure. Up to 60% of all motor failures can be attributed to bearing issues. The most prevalent causes of bearing wear are usually twofold: overloading and insufficient lubrication.

For instance, the calculated bearing design life for a 100kW motor is approximately 40,000 hours. Operating under axial or radial load increased by 30% or more over a certain period can reduce the bearing life to one-third or even lower than its original value.

Mechanical stress often leads to vibration. Motor vibration can induce mechanical friction, which leads to abnormal wear of parts. Vibrations can also cause the insulation of motor windings to peel off, resulting in winding shorts or grounding faults.

Some common causes of vibration include poor balance in the rotor, an unstable foundation, and mechanical misalignment. If a motor’s vibration amplitude is 20% above its rated value, the lifetime of the motor may be reduced by about 30%. In some high-precision applications, even slight vibrations may cause malfunctions in equipment.

Electrical Stress

Electrical stress has a significant impact on the service life of a three-phase motor and generally includes voltage fluctuations, current imbalance, and harmonic interference. During normal operation, the operating voltage of a three-phase motor should be controlled within ±5% of its rated voltage.

Excessively low voltage can lead to insufficient torque in the motor, and thus increased load. High voltage, in turn, causes the motor to overheat and may break down its insulation layer. Studies show that when the motor operates with a voltage exceeding the rated voltage by 10%, the heat generated in its windings increases by more than 50%.

Another important factor affecting the service life of three-phase motors is current imbalance. In general, the three-phase current imbalance rate should be controlled within 2%. If the imbalance rate reaches 5%, a large negative sequence current will be generated by the motor, which will result in overheating of the rotor and reduction in torque stability.

In this case, the temperature rise of the motor windings may increase to 1.4 times the rated value, causing winding burnout in extreme cases.

Frequent Start-Stop

Frequent starts and stops place tremendous stress on both the mechanical parts and the windings of a motor. The inrush current at startup is usually 6 to 8 times the rated current, causing instantaneous heating in the windings, accelerated wear of the bearings, and torque shocks that can cause mechanical parts to fail.

In practice, frequent start-stops should be avoided as much as possible. For heavy inertia loads or applications with frequent speed changes, soft starters or frequency converters should be applied to reduce startup shocks.

For instance, a 75kW three-phase motor, if its number of starts is more than 20 times within one day, may see its lifespan shortened by more than 50% for both its windings and bearings. Therefore, soft-start control strategies are recommended for motors used in frequent start-stop processes, as they reduce mechanical and electrical stresses, thereby extending the actual service life of the motor.

Environmental Factors

The influence of the environment on the life of a three-phase motor is often underestimated. High temperature, high humidity, corrosive gases, dust, and vibration all have varying degrees of impact on motor lifespan.

Under high-temperature conditions, the heat dissipation of the motor worsens, leading to a larger temperature increase in windings and faster aging of insulation materials. High humidity will lead to lower insulation resistance, increasing the possibility of leakage and short circuits. According to statistics, when the ambient temperature reaches 40℃ and relative humidity is greater than 85%, the real service life of the motor is only 60% of its designed life.

Corrosive gases, like hydrogen sulfide and chlorine gas, can corrode metal parts of the motor, insulation materials, and winding surfaces, eventually leading to electrical or mechanical failures. Dust can block heat sinks and cooling ducts, reduce cooling efficiency, and even enter the bearings, causing lubrication failure.

Therefore, motors used in these environments should have a high protection rating, such as IP55 or above, and consider the use of anti-corrosion coatings and sealing designs.

Motor Load Conditions

The working condition of a motor is determined by its load conditions, directly influencing the operating state of the motor and affecting its service life. The main parameters for load conditions are load magnitude, load fluctuation, and load type.

Under conditions of overload, the current increases, resulting in increased heat production in the windings and accelerated insulation aging. It is estimated that when a motor runs at an overload of 10%, its winding temperature rise will be about 15% higher. If it keeps working in this state for a long time, the service life will drop dramatically, down to only 30% of its normal lifespan.

Long-term light load operation will also bring down motor efficiency and cause mechanical component wear. For example, long running at less than 30% rated load will lead to a huge increase in losses inside the stator and rotor cores, and the bearings and couplings may fail due to poor lubrication.

Both overload operation and light-load operation will adversely affect motor life. Therefore, when choosing and using a motor, extreme load operating conditions should be avoided as far as possible.