How IE Series Motors Enhance Industrial Centrifugal Fans

In the case of industrial centrifugal fans, IE series motors aid in driving performance and increase energy efficiency. Consider huge factories like chemical plants, steel mills, or companies within the metallurgy industry — places where solutions are required to process air filtration and high-temperature gas emissions on a daily basis. This is where the IE series motors really shine.

For instance, a steel plant. In these kinds of environments, the ventilation system is not just an afterthought – it’s necessary to keep air flowing and gases under control, especially in places like smelting where temperatures can go over 1000°C. With IE series motors you get up to a 15% improvement in efficiency compared with non-IE counterpart, that means less energy cost for your power budget. For a plant running several centrifugal fans 24/7, these savings may tally to hundreds of thousands over the course of a year.

But IE series motors are not all about saving as much energy as possible. They also provide high torque and power, important features when you’re driving large-capacity fans to handle the airflow — often more than 100 m3/h (mmF/). A motor that cannot maintain reliable, high-torque operation under heavy loads would be anathema to the entire ventilation system and could lead ultimately to operational downtime.

With the ability to cost a facility more than $100,000 for every hour of downtime experienced in some sectors, the extended 25K operational hours expected service life of IE motors makes it not just a wise choice but an essential one. They are ideal for applications under demanding industrial conditions as these motors can deliver steady power even in hot/vibrational environments (such as it is experienced at a steel mill or chemical plant).

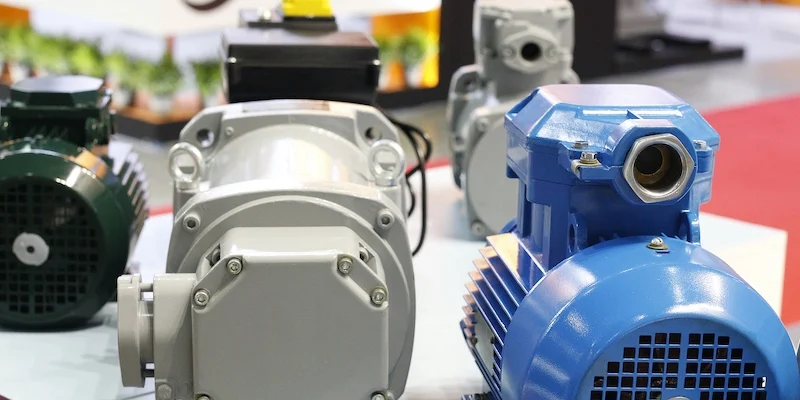

IE series motors are extremely versatile as well. This enables them to take the place of existing centrifugal fans in many configurations, making it easy for manufacturers across all industries to upgrade without costly overhauls. A metallurgy company, for instance, can replace old motors with new IE series models and quickly give itself a richer fuel diet while cranking up the speed of its grinding rollers.

This is not just theory as important industrial players in Asia and Europe have already begun their IE series motors journey under the pressure of worldwide energy regulations and low carbon emissions expectations. More than a component, the IE series motor delivers true energy savings that drive down overall operational costs and position it to be an important part of high-efficiency industrial ventilation strategies.

The Role of IE Series Motors in Driving Axial Fans

These fans operate as the primary source of air movement in large-scale HVAC systems, tunnels and subway venting. Next, think of how much air has to move through a subway station in the course of rush hour — we’re probably talking thousands of cubic meters per minute. Enter the line of IE series motors, which have been designed to provide plenty of power and efficiency for these systems.

Think of a new high-rise building, for example. These buildings have large HVAC systems, the axial fans of which circulate air over many stories to assure that workers and residents are in a comfortable environment. Most crash-over-IP systems are in operation up to 20 hours a day and when you consider energy is one of the three most expensive things it’s not as easy as just turning off equipment every time someone leaves for home. Using the IE series motors can make a difference of 10-15% in energy efficiency, this figure may seem small. At smaller scale these differences are unnoticeable, but over the course of a year can be worth tens of thousands in energy costs to even just one building with hundreds kW using motors.

The cost is not the only thing. IE series motors likewise offer improved air flow rate as well as security. Take tunnel ventilation, you need a certain airflow to carry away exhaust gases and keep air quality within the appropriate limits. Poor air exchange because of the unstable power from a motor was not only threatens safety but also regulatory-compliance. The power output is steady from an IE series motor, so that the axial fans can maintain a stable speed of airflow through those long subway tunnels that in parts measure miles.

The other advantage is the motor life. When you have a mechanism like underground subway systems, which are hard and costly to maintain, you need motors that can withstand the test of time. IE series motors are designed to work for amounts higher by orders of magnitude than conventional motors. This makes them well-suited for use in tunnels and subway stations, where high-humidity or dusty conditions are prevalent. For instance, in a subway system relying on axial fans to run for 24/7 with low downtime. Those fans, when mated up to IE series motors, could also be spinning 24/7 for years on end and would have no business requiring any sort of attention or replacement.

Across the world, cities are implementing measures to bring their infrastructure in line with this level of energy efficiency. To comply with increasingly stringent regulations, governments and companies are turning to technologies such as the IE series motors in hopes of reducing operating costs.

How IE Series Motors Optimize Boiler Fans in Power Plants

Boiler fans play a big role in the lifeblood of power plants, with functions for both forced draft (meaning pushing air into a boiler) and induced draft (drawing exhaust gases out). In a large power plant where boilers are running on fuel day and night, you need motors that can run non-stop under heavy load for one or 2 years without productivity loss.

For instance, imagine the energy needs of their boiler system for a power plant. These are motors that have to function with a high degree of accuracy — delivering air into the furnace at precisely the right flow rate, so as not only provide enough oxygen for proper fuel combustion (too little or too much and you get incomplete burn which is bad news) but also never over fire. IE series motors ensure that with a waste can be generated energy up to 10% of the efficiency, making arrangements on optimizing this foreign mixture air fuel inside boiler. At larger plants burning a few thousand tons of coal or natural gas every year, that kind of efficiency would save millions in fuel costs over the course of a year.

The high torque-to-power ratio for IE series motors is also a major advantage in driving large boiler fans. Just to put things in perspective — an average boiler fan of a power plant can handle airflows well above 500,000 m^3/hr. Employing IE series motors with high torque characteristics, these fans maintain their nominal airflow even when load conditions vary such as during a plant start-up or shut-down where power generation in the facility is increased / decreased. Having no control over this timing scale is tantamount to disordered combustion, thereby higher fuel usage and increased emissions are in store.

Then there is maintenance to consider. Downtime is very expensive in a power plant. Even just an hour of shutdown for service or repair can result in $100,000 loss from production alone. Designed for durability and longevity of operation with a typical lifespan of over 30,000 hours IE series motors are constructed to lower the number of maintenance intervals. As an example, a power plant that uses IE series motors could find maintenance cycles extending from every 6 months to every 12 months — less time between repairs combined with better reliability and features provide many operational cost savings.

Moreover, regulations that require power plants to reduce their emissions have become more stringent. Today the IE series motors assist in raising up the combustion efficiency ratings of your boiler process. Reducing the amount of unburnt particles in the exhaust gases as a result, which lowers CO2 and NOx emissions when air and fuel mix just right. Efficient IE series motors are an essential part of this makeup — with power plants across Europe and the USA facing tough emissions targets to meet, every efficiency gain is a step in the right direction.

The bottom line is that using IE series motors for boiler fan applications goes beyond saving electricity — it leads to an optimized solution. Power plants the world over are providing a beneficial double edge economically and ecologically worth, backing that these engines play an essential role in keeping modern energy production systems operating at full capacity.

How IE Series Motors Power Cooling Tower Fans for Maximum Efficiency

Cooling towers are essential to the thermal balance in power plants, especially for cooling down the water that boils inside their boilers. Empowering Effective Air Flow — The Vital Role Of Cooling Tower Fans Without proper air circulation, the entire cooling process could go in vain making it crucial to look for high-quality tower fans involved. IE series motors like those used in this example can deliver the power and efficiency necessary to drive these fans effectively.

Let’s break this down. An average-size cooling tower at a large power plant can handle water flow rates of up to 100,000 gallons per minute and the fans have to be in operation constantly so that they are blown away as soon as possible by cooler air. IE motors are capable of delivering a power gain to the tune of 8-12%, for air conditioning systems and making cooling operations more energy efficient can translate into lower electricity bills while assuring optimum levels of cooling effectiveness. Propulsion System Conversion: A diesel engine ship benefits greatly from replacing its drive system with an electric motor. And yet, for a large facility spending millions of dollars per year in operational expenses those efficiencies have much broader implications.

It all comes back to the power being delivered by the motor. Cooling tower fans are typically exposed to the most challenging operating field conditions — sometimes a combination of high humidity, or temperature fluctuations and chemical vapors. IE series motors are designed to operate under these exact conditions, providing fans with constant power over hours on end — up to 20 or more hours a day. You also get a true long-life motor – actual length of up to 30,000 operational hours between having to perform the larger maintenance operations which is an essential feature when you want as little downtime from unscheduled issue shutdowns.

As an example, a Texas-based power plant decided to upgrade its cooling tower systems with IE series motors, and in doing so generated immediate improvements. In cooling, the plant saw a 10% decrease in energy consumption and even more so: steady air flow meant circulating water cooled faster. It was not only more efficient process for cooling but ultimately improved the plant overall energy generation efficiency as well.

The improvement of airflow and the cooling solution also contribute to extending the entire vehicle’s lifetime as well. When you have a cooling situation running at full capacity, the rest of your vehicle does not need to work as hard to cool it down which means less wear and tear on other parts leading to costly repairs or replacements. For the large cooling towers, these savings of scores of thousands of dollars per year in operational costs are not uncommon.

As energy efficiency is increasingly regulated, the world of power plants cannot ignore what IE standards can offer with these motors. When these motors are installed in cooling tower fan systems, facilities can minimize their carbon footprint and operation costs while assuring reliable performance for years to come. All of that will also help plants keep pace with an increasingly regulated industry.

How IE Series Motors Boost Efficiency in Dust Collection Fans

For many industries including manufacturing, chemical processing, and mining; dust collection fans are a critical component of maintaining a consistent clean environment for safe working conditions. Additionally, they contribute to cleaner air and the highest possible eco status when used in concert with IE series motors.

For a large-scale manufacturing plant, for instance. This dust collection system has to handle incredible volumes of air – up to 150,000 cubic meters per hour — in order for it to collect the small particulate matter that can be harmful if we breathe them. Enter the IE series motors which deliver power with high efficiency, and are usually 10-12% more energy-efficient than standard motors. When you own facilities that run this type of system all the time, though these efficiencies end up representing savings in energy costs to the tune over $10k+ annually.

As the IE series motors represent, strong power and torque are key to generating a steady airflow capable of entraining dust and blowing it through high-filtration media. Dust collection fans for fields such as cement or those working with wood and metals, deal mostly with heavier particulates that may back non-sturdy systems. IE series motors maintain a strong steady airflow to keep these systems running smoothly, even in dusty conditions;

In addition, these motors are intended for laboring in harsh industrial conditions often crowded with dust, humidity, and high temperature. That is important because just one failure in a dust collection system can result in hundreds of thousands to millions per day shutdowns for industry, fines from environmental non-compliance or even health hazards. The lifespan of up to 25,000 operational hours helps keep regular maintenance work at bay and the machine running in top form for an extended period… which further increases the overall lifecycle of your dust collection system.

Growing air quality regulations have driven a leading mining firm to retool their existing dust collection systems with IE series motors – an example of the opportunities manufacturers are facing today. The upgrade led to a 15 percent increase in dust capture efficiency and produced a 12.5 percent electricity savings, both of which combined paid for the overhaul within months. This action not only prevented the company from incurring bad-actor fines for failing to meet environmental standards, but it also had an added benefit by making operations safer and workers healthier due to a reduction of airborne particulate matter.

In the industrial world of today, where regulatory demands are growing by leaps and bounds, dust collection fans featuring IE series motors deliver more than financial savings but also serve as an important element in maintaining compliance with regulations – whilst promoting safety and efficient operations.