Balancing the load on a three phase motor may involve periodic checking of the voltage and current at each phase, ensuring that the loads are correctly balanced, and improving the power factor using a capacitor bank. In addition, when necessary, the load could be dynamically adjusted using an automatic balancer.

Check Voltage and Current

The principle of load balancing is to keep the voltage and current of each phase close. Check the three phase voltage and current of the motor by using appropriate measuring equipment, such as a multimeter or clamp meter. Each phase voltage is supposed to be equal or very close to the standard value. For example, the voltages of L1, L2, and L3 should be about 380V for an ordinary 380V motor, with a difference of no more than 2-3%. If higher than 5%, that is already serious load imbalance.

It is of prime importance to check the current, especially with big loads. You can take phase current measurements using a clamp meter. Normally, phase current differences should not be more than 10%. If the current difference is big, for example, L1 is 50A, L2 is 45A, and L3 is 55A, this may indicate uneven load distribution that needs adjustment.

In motor operation, voltage and current stability is very important. If one phase of voltage or current is too high or too low, it will not only lead to load imbalance but may cause overheating of the windings, reduction of efficiency, and even burnout of the motor. Thus, it is required to check the voltage and current regularly in order to keep them within the normal range, as this is a prerequisite to ensure that the motor operates normally.

Evenly Distribute the Load

Any equipment or load applied to a three phase motor must be divided as equally among the three phases as possible. This becomes much more critical when several devices are operating within a system. Poor load division may result in too much current operating on one phase and another phase operating with too little current. Over time this can cause undue wear to take place on the windings of one motor phase.

Balancing the load requires an understanding of the power and current each device needs. Suppose there are three load devices, A, B, and C in a system, each rated for 10kW, 8kW, and 12kW, respectively. These should be connected on different phases, with device A, for example, on L1, device B on L2, and device C on L3. For instance, in this way, the load would be balanced in theory.

There is not always a constant demand of load. A certain part of the equipment may require intermittent power. While designing the system, therefore, fluctuating load conditions should be considered and, when necessary, redistribution of the load should be done by altering the phase at which the equipment is connected. In case one phase is usually the highest while others stay low, you must adjust part of the load to the other phases for it to be balanced in general.

Regularly Monitor and Adjust

The balancing of the load is not a one-time work; with time, the condition of the equipment will change with the environment and power requirement, for which the load will have to be redistributed. Thus, the practice of load balancing requires close monitoring and adjustment at regular intervals.

In case of big-size industrial equipment and continuously running production lines, a check on the motor at least once in a month is recommended for the purpose of keeping the load balanced. You can log the measured current and voltage from each measurement and relate this to previous data to indicate whether adjustment is required. For example, if you find that one phase current has increased 10% from the last measurement, then you have load imbalance and you will have to transfer part of the load to another phase.

The process can be greatly simplified by the use of data loggers and other automatic monitoring devices. Such devices can monitor continuously the three phase voltage and current for any kind of imbalance, automatically sounding alarms at needed levels to assist operators in making timely adjustments.

Use a Capacitor Bank

Capacitor banks play a major role in electrical systems, mainly where large numbers of inductive loads such as motors and transformers are present. Inductive loads decrease the power factor of a system, which, in effect, increases the reactive power within the system. Such a scenario might also lead to current deviations that can cause load imbalances.

A capacitor bank can be installed to improve the power factor effectively. When the power factor improves to above 0.95, fluctuations in the current of the system will be reduced and the voltage of the three phase motor will be more stable to maintain the balanced load.

If the system power factor is 0.7, then the capacitor bank added to increase the power factor to 0.95 will not only decrease the current deviations of the system but also the energy consumption of the equipment and prolong the life of the motor and other equipment. In some large power systems, capacitor bank installation can effectively reduce the total current of the system by 20% – 30% with the aim of balancing the three phase load and reducing the loss of power.

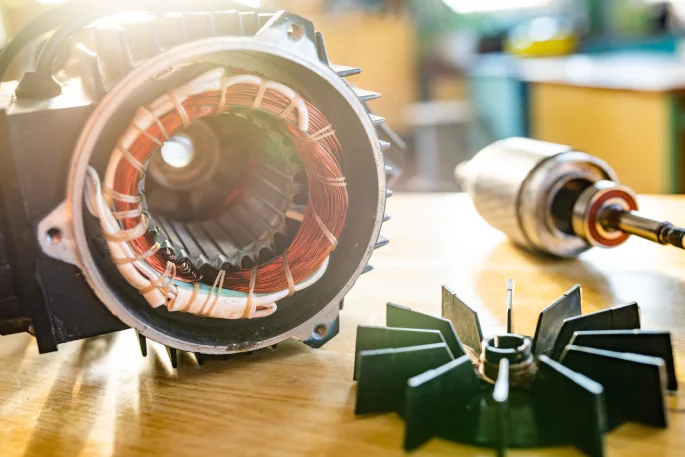

Check Mechanical Problems

The second most common cause of load imbalance is mechanical problems. For example, worn or misaligned motor bearings cause unequal motor loading and therefore the balance of the load. This condition is usually accompanied by warning signs such as increased motor vibration, a noisier tone, or a sudden increase in the current of one phase.

To avoid these, the mechanical parts of the motor should be examined periodically. Check if there is any wear on the motor’s bearings, if it is well greased, or if the rotor is out of alignment. These are basic steps toward ensuring the motor runs well.

In extreme cases, mechanical problems can cause a sudden increase in motor load. For example, when the bearings are badly worn, one phase of current can increase sharply even to surpass the rated current of the motor. This may not only cause damage to the motor but also create a chain reaction of failures for the equipment. So, it is necessary to perform a mechanical check on the motor comprehensively every three to six months to find out potential problems and solve them before they actually occur.

Use Automatic Balancers

For some high-demand industrial systems, inefficient or even unrealistic is the thing when manually adjusting the load. In that situation, an automatic load balancer would do it a lot more effectively. An automatic load balancer can keep monitoring in real time the current and voltage in the system and thus change the distribution of load automatically upon the detection of a load imbalance to balance the three phase current and voltage.

Large values of fluctuations within use in loading and high stability—for example, automated lines of production or high-power industrial motors. If one phase surges with its load after an automatic balancer is installed, the device may quickly adjust the load on other phases to keep it balanced, preventing overload within the system or overheating of a motor.

When using a large workshop, many high-power devices could start up at random. These might lead to serious load fluctuations. The automatic load balancer automatically adjusts the system for safe operation of the motors and other devices.