To optimize the power consumption of a three-phase motor, first, you should choose high-efficiency motors, such as IE3 or IE4 motors, which can reduce energy consumption by 20%-30%. Second, use a frequency converter to adjust the motor speed, which can save 20%-50% of energy when the load is light. Additionally, regular maintenance of the motor, keeping the bearings and brushes in good condition, can improve efficiency by 10%. Installing power factor correction devices to increase the power factor to above 0.95 can reduce power waste by 10%-15%. Finally, ensuring load balance can reduce motor power consumption by 5%-8% and extend the equipment’s lifespan.

The Importance of Motor Selection

Picking the proper motor is as important to an engine-driven vehicle as picking the appropriate heart for a body; the motor needs enough power to do its job; use too much, and it burns holes or uses more energy than required; uses too little power and the job at hand becomes an endurance race. Studies have established that the energy consumption of a motor increases by at least 15% when it is rated for 20% or more power than is actually required. Hence, the motor needs to be in sync with a real load.

Up to 20–30% energy saving Using more efficient motors, i.e., IE3 or IE4 standard efficiency motors. At the same time, these high-efficiency motors are more expensive at the beginning; over the life of the motor, the energy savings characteristics enable it to pay back within two years. Reduce fan or pump energy use by 10%-20% using high-efficiency motors.

The Application of Frequency Converters

The frequency converter is the “magic tool” in motor optimization; it can control the speed of the motor so that the motor does not have to run all over when there is only light or partial load. The frequency changer, combined with traditional motors, can adjust the speed according to the actual load and reduce the energy consumption from 20% to 50%.

A pump equipment, for example, lowering the engine speed by 10% may generate energy financial savings of up to about 20%. The frequency converter can also solve the problem of mechanical wear, such as that caused by frequent starting and stopping on production lines; in this way, it will be possible to increase the life utility of the equipment. Meanwhile, the frequency converter’s intelligent control system can enable companies to respond more precisely to production needs, particularly in an environment where speed is required.

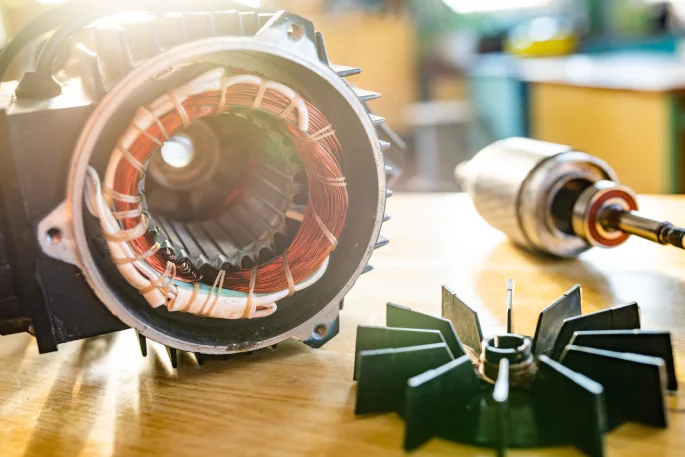

Motor Maintenance and Upkeep

A motor is like a car. The better scheduled “maintenance,” the further you can get it to “run.” An unmaintained motor can demand more energy and damage equipment. A motor maintained as per its condition loses time and power consumption by 5%-10% as the data denotes. Running bearings oiling and losing short brushes, the frictional loss and heat generation are reduced, and the efficiency is increased by about 10%.

One of the easiest and most forgotten operations to be performed is cleaning the dust accumulated once or twice a week inside the motor. Dirt can create problems with the heat dissipation of the motor that heats up to 5-8C or even more just for each one C higher; you lose a % of energy consumption. Regularly cleaning can lower energy consumption by 3%-5% so it saves energy. Another advantage is that for equipment working for a relatively long time, regular maintenance can help prolong life expectancy, as unplanned breakdowns may result in additional costs due to lower productivity in the absence of repairs.

Power Factor Correction

The power factor is a measure of the efficiency with which electrical energy is used. The consequences are an increase in reactive power, which puts a strain on the grid and means that more energy needs to be generated for the same output, and overall system efficiency drops. Power factor is improved from 0.7 to more than 0.95, power loss can be reduced by 10%-15% using such power factor correction equipment like parallel capacitor banks.

Implementing power factor correction equipment at another factory improved its power factor to 0.96 instead of the current 0.78, decreasing its electricity bill by about 12%. Investment in power factor correction equipment is a wise choice, and it usually covers up its cost through the saved cost of electricity within 1 to 2 years for factories that are high in motor capacity usage. This ensures neither energy wastage nor any grid instability to the vertisities of burdens.

Load Balance

Balanced loading of the three-phase motors is also important in reducing power consumption. If the three-phase current is imbalanced, one phase of the current of the motor may be forced higher, meaning that it would overheat and increase losses. When the deviation of the three-phase current is more than 10%, the power consumption of the motor increases by 5%-8%, according to research.

Load balancing systems can monitor how the current pulls in real-time, and thereby effectively adjust load distribution on the motor to avoid excessive power unbalancing. When used for large compressors/fans running in a balanced loading state energy savings could be realized up to 7%. Load balancing ensures a longer motor lifespan and decreases maintenance costs due to overheating.