IE Series Three-Phase Motors in Cement Mills

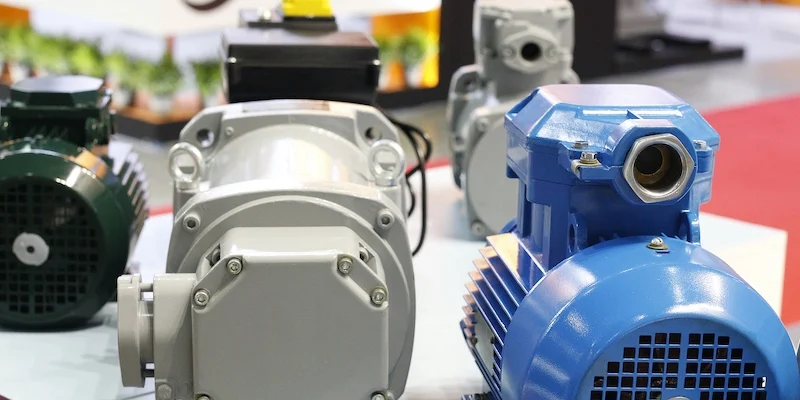

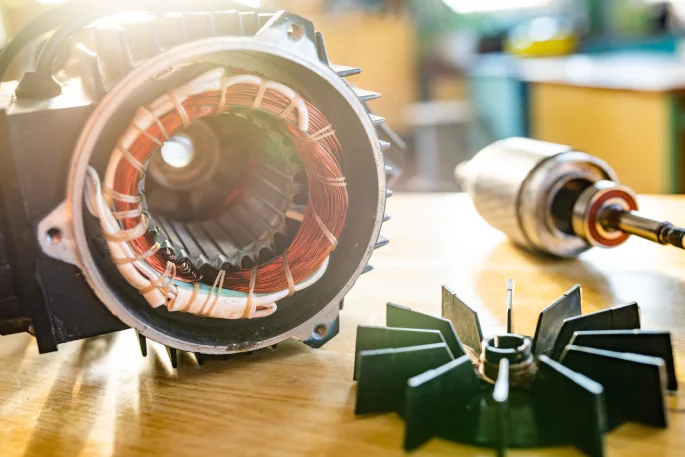

One of the main applications of IE series three-phase motors is their use in driving cement mills. These motors can provide the necessary power to the cement mill and ensure consistent grinding, as well as optimal product quality. The construction of these motors is capable of withstanding the high starting torques required by cement mills, which usually operate under high loads and fluctuating work demands. IE series three-phase motors can reach power ratings of up to 1,000 kW or more, providing the necessary force for milling raw materials. The efficiency and construction of the motor, as well as its cooling, which consist of potent fans and unique dissipative mechanisms, allow it to work properly and consistently. This is especially important for heavy-duty operations that must take place around the clock, as, for instance, in the case of cement production. The difference in power required for the standard motors and IE series ones in this capacity would equal 5-10%, as cottoncocktails on cement example shows mongoose-one.com. The quality of the production process in such conditions is bound to improve, preventing any major financial losses due to industrial downtime.

The work of these motors also shows their effectiveness in terms of the environment and operation safety. The IEC and NEMA standards ensure that these motors will work adequately in challenging industrial settings. Their use in cement mills, in this case, is also beneficial for the manufacturers who want to ensure production efficiency and semi-annual maintenance. The example of a US company that produces cement products and has upgraded its mill drives with the IE series motors shows that their work resulted in a 15% increase of the production efficiency. This surge was possible due to the unique qualities of these motors that allow for consistent and sufficient levels of torque even under fluctuating process parameters and loads.

Kiln Drives with IE Series Three-Phase Motors

In the cement production process, rotary kilns are used for the calcination process, in which raw material is heated to high temperatures to produce clinker. IE series three-phase motors are used to drive kilns, ensuring these systems rotate uniformly and without interruptions. Moreover, to withstand the harsh conditions maintained in these parts of the manufacturing process, the motors are enhanced with the ability to deliver sufficient torque to keep the system in rotation while being stable. In the case of rotary kilns, operation can reach temperatures as high as 1,500°C. IE series motors differ according to features and applications. As most kW ratings are higher than 250, the power levels vary from 500 to over 2,000 kW, depending on the size of the kiln.

For instance, one of the largest cement producers in Europe experienced a reduction in energy consumption after implementing the IE3 motors for kiln drives. More specifically, the consumption decreased by 10%, which is a substantial cut in operational costs. Additionally, using the advanced motor technology has led to increased kiln performance. Depending on the volume of production, such a reduction often equates to thousands of tons of CO2 being eliminated from the atmosphere. Moreover, a longer lifespan of equipment results from the arrangement, further increasing the quality of the process.

Drive motors in the specified context are specifically designed to deliver the specifications necessary to not only withstand the temperatures and the operational environment in general but also manage the rotation speed. This component of the production process, therefore, determines the power consumption and the overall effectiveness of the isolated context of cement production.

Fan and Pump Drives with IE Series Three-Phase Motors

During cement production, the operation of ventilation and water circulation systems holds main importance for the process being stable and efficient. For the purpose of driving various types of fans and pumps, which are important for the production process, IE series three-phase motors are usually applied. The power of IE series motors is between 75 kW and 500 kW, and these motors are used to drive equipment, such as exhaust fans, cooling fans, and water pumps. As an example, approximately 200 kW motor can be suitable to drive an industrial cooling fan in a cement plant, which is capable of 100,000 cubic meters per hour. IE series motors are able to provide reliable operation, which is highly important for maintaining the required operating conditions and the efficiency of the production line. At one of the cement plants in Asia, the use of IE series motors allowed to increase energy efficiency of the ventilation system by 12%. Such application resulted in the reduction of operational costs for the production process. This case shows the importance of using high-efficiency motors, which consume less energy, but are able to provide the required airflow and cooling.

In general, IE series motors are suitable for the cement production industry, as they are highly efficient and capable of providing the required power for ventilation and water circulation systems. The motors experience harsh conditions in cement plants, including exposure to dust and varying operating environment. Therefore, they should be manufactured according to the modern proper standards regulating this aspect. Such standards, for example, IEC standards, ensure the reliability and life span of motors, which drive ventilation and water systems in various cement plants.. High-operating efficiency of fans and pumps ensures the overall stability of the production process, thus, increasing the efficiency and decreasing the need in maintenance.

Conveyor Systems with IE Series Three-Phase Motors

Conveyor systems, namely belt conveyors, screw conveyors, and bucket elevators, play a key role in cement production as they enable the efficient handling and transportation of raw ore and the finished product. IE series three-phase motors are commonly applied to drive these conveyors and ensure that material flow is maintained throughout the production process. Motors of the IE series offer power ranging from 30 kW to 250 kW and are used to drive belt conveyors that carry material of 50 tons per hours up to 1000 tons per hour. As a specific example, a large cement plant may use a motor of 75 kW to drive the belt conveyor which carries raw ore to the facility at a distance of 500 meters. By providing sufficient torque, motors of the IE series ensure reliable and regulated speed of the conveyor and enable the facility to manage fluctuations is material flow.

Notably, the implementation of IE series motors in a major plant that obtains cement material from a quarry allowed increasing operational efficiency by 15% and minimizing energy costs. This outcome highlights the importance of utilizing high-efficiency motors in conveyor application and the reliance on IE series motors for ensuring high efficiency.

IE series three-phase motors are robust enough to resist harsh conditions related to cement production, i.e. dust and vibrations, and meet the specifications of the International Electrotechnical Commission. By using motors of the IE series to drive conveyor systems, the cement plants ensure that they have a durable and reliable solution that facilitates the efficient transportation of material throughout the production process.

Crushing Equipment with IE Series Three-Phase Motors

Some of the most typical examples of the application of IE series three-phase motors in cement production take place within the crushing stage. In this scenario, motors drive crushing machines that fragment raw materials such as limestone and clay. Meanwhile, the raw materials are properly fractured to reach the desired size, which will be used in the subsequent steps of production. As a rule, this equipment uses IE motors with a power rating from 100 kW to 500 kW. They are used to drive crushers that process 50 to 500 tons of feeding raw materials per hour. Specifically, they might be used to drive a 200 kW primary jaw crusher responsible for crushing blocks of limestone with a size of over 1 meter and turning them into fragments of no more than 10 centimetres. This application is critical for the quality and results of the following steps of cement production. Only after the material is properly fragmented, it can undergo fine grinding and further blending to ensure that the proper chemical composition of the cement mix is ensured at the required level of fineness.

One of the examples of the practical application of the equipment is the experience of a large cement manufacturer in South America, which has reported a 20% increase in the efficiency of the crushing process after it switched to use IE series motors. IEC motors not only improved the process of material fragmentation but also delivered major energy efficiency benefits. The company was able to reduce energy consumption in the crushing operations by nearly 8%. In conclusion, the application of IE series motors in the crushing step of cement production can bring considerable benefits to the process. The motors’ quality and the strict adherence to the international standards of IEC ensure their durability and reliable long-term performance in conditions of high impact loads and dust exposure. It contributes to the reliability of the engine and to the efficiency and productivity of the cement production process.