Centrifugal Pumps in Real-World Applications

Centrifugal pumps are used for multiple purposes in agriculture including, of course, the field irrigation. A single-stage centrifugal pump is capable of moving up to 500 gallons per minute of water, which adds the needed capacity for large irrigated farming operations. In terms of efficiency these IE3 motors make the difference. This can improve operational efficiency by up to 5%, which in turn reduces energy costs a great deal over time (Opex). Upgrading to more efficient units, however has allowed many farms across Australia reduce their annual energy usage by between 15% and 20%.

Centrifugal pumps are the reason that city and town water pressure is constant. A multi-stage centrifugal pump can deliver pressures to 200 PSI making it capable of driving water through miles and miles of piping system. After all, this level of performance is necessary for any household and business and public facility to thrive. For instance, in Los Angeles a line of pumps are used to move water across the vast metro area and those pumos like efficient high-performance centrifugal ones.

Centrifugal pumps are helpful to the HVAC (Heating, Ventilation and Air Conditioning) industry as well. Accurate control of flow is needed for heating and cooling systems due to sensitivity to specific temperatures. Due to Pipe Hydraulics, up to 20000Lts/hr Hot or Chilled water is circulated in a conventional commercial building by Centrifugal Pump This rate of flow guarantees the even dispersion of energy and avoids areas for example very hot or cold spots inside building, in addition to decreasing operational force on heatingsystem.

The lower the operational costs, with a more efficient motor, says John Walker, senior engineer at GreenTech Solutions. And this is true of high-efficiency motors, like those in the IE series as well — whether you are moving water through agricultural fields or air up to offices; investing more on an efficient motor will save money and equipment life.

On the other hand, in reliability terms centrifugal pumps with high efficiency motors can operate 10.000 hours continuously without requiring great maintenance efforts. This duration is one of the reasons they are more commonly used in a variety of industries. To the bottom line-focused companies, that means lower downtime and repairs with literally thousands of dollars saved annually.

Submersible Pumps in Demanding Environments

Being a durable and reliable water management solution, submersible pumps are essential in industries that need them the most. From draining floodwater out of old coal mines to dealing with waste water, they get the job done. For example, a traditional deep-well submersible pump can work at depths of 200 or more meters and draw water from the most difficult locations. The versatility to reach depths of this magnitude takes on added importance when it operates down hole, such as in a mining setting whereby groundwater must be dewatered efficiently so that work can continue safely and profitably.

Wastewater treatment plants are also prime candidates for submersible pumps due to the tremendous performance available from three-phase motors (IE series). This can easily manage solids up to 100mm in size which makes sure that it allows processing not just water but debris and sludge too without any clogging. No more so than in sewage systems, where even a few minutes downtime can be catastrophic for the public and to the finances of involved authorities.

One of the main sectors to depend on Submersible pumps for dewatering is mining industry. A submersible pump in a normal mining operation would always have to move at least 1,000 cubic meters of water per hour to maintain continuous and useful functions. In this case, durability and efficiency are non-negotiable. These IE series motors typically have a very high protection rating sometimes going up to IP68, and is engineered as such so that it can withstand extremely harsh abrasive conditions in mines. Such protection would ensure that the motor will be able to continue working without breaking down under normal operations which may eventually happen with lower standard equipment.

Michael Stone, an industrial water management expert said: “In fail-light environs, you want gear that will not give up the ghost. That is why companies in crucial sectors go for the submersible pumps with high-efficiency motors. And efficiency, in this case, doesn’t simply mean using less energy — it means having the pump working effectively on a daily basis under some of the most punishing conditions anywhere.

When used in deep-well applications, they enjoy a similarly long service life. Pumps having IE series motor can work for years with low maintenance and still they are capable enough for continuous duty. The long services life of the Centrifugal are responsible for reducing the total cost, and such an investment being wise because it will give a performance and at reasonable low price.

Chemical Pumps in Hazardous Applications

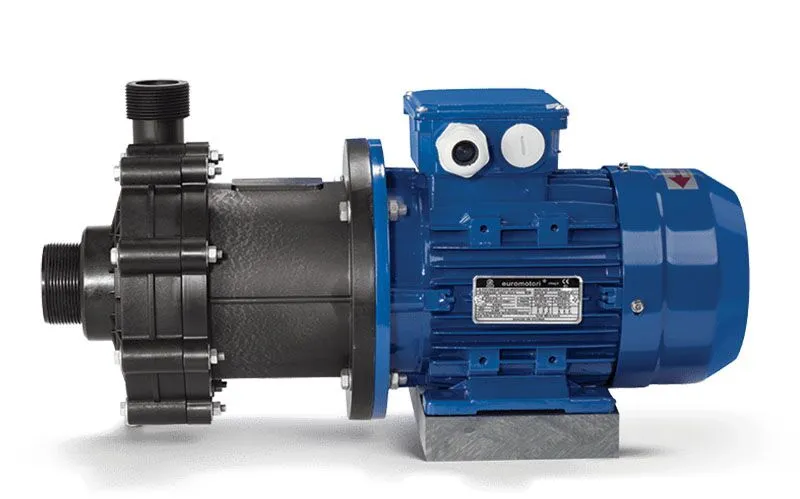

The chemical industry depends a lot on these kind of pumps because it deals with very hazardous chemicals like acids, alkalis and industrial waste. For instance, a standard corrosion-resistant pump has the ability to carry anywhere up to 100000 liters of acid per day without suffering any setbacks even in highly aggressive parts. Being able to manage those types of quantities of hazardous fluids without a spill or break is extremely important for maintaining workplace safety and productivity.

Magnetic drive that are used in chemical processing plants add an extra layer of safety and have a very unique design. They are removing the weak link in traditional pumps, i.e. mechanical seals. In contrast, with a magnetic coupling – where there is no physical touching of shaft to flow stream – the absence of leaking would prevent mag drive pumps from being used as they are today for moving dangerous chemicals. Seal damage is responsible for 90% of chemical spills due to pump failures; all potentiality obviated with the mag drive.

Powering patch rings, the IE series three-phase motors of NETZSCH RumerIS have proven themselves with their energy efficiency and reliability. Upgrading to an IE3 motor can cut energy usage in a standard chemical plant by 15%, which equals thousands of dollars per year in savings from your operational budget. The most important part is that the motor can last decades in continuous operation without overheating or deteriorate and keeps a plant up and running. If you are dealing with dangerous chemicals, the last thing that you can afford is an unexpected shutdown due to motor failure.

The chemical industry, an area where requirements are strict anyway on account of explosion protection for motors translates into high additional benefit. IE series motors are often provided with ratings such as IP55 and above meaning they both dust tight, & protected against water jets. This is important when dealing with liquid which if inadvertently spilled can have severe reaction compounds to the environment. In chlorine processing plants, pumps with IE series motors provide a reliable research tool even under the harshest conditions.

Dr. Lisa Morgan, a chemical plant safety specialist at Sandia National Laboratories agrees: “Chemical operations are built on precision and safety.” Reliability is everything at this point (this is where high-efficiency motors are useful). IE magnets and motors are recommended for use in any pump configuration that moves acids through a corrosion-resistant pump, or when handling volatile liquids where used with a mag drive pumps.

Precision: For waste treatment applications, the IE series motors are ideally suited with chemical pumps to remove harmful toxic wastage. One example of this is a plant that processes 500,000 litres if waste per month needs pumps to run continuously and with minimum maintenance. That is great news for IE series motors, which revel in such demanding applications and provide the necessary torque alongside an inherent rigidity to handle fluctuating loads without missing a beat.

Boiler Feed Pumps in High-Pressure Systems

These pumps are provided in boilers to pump feed water through economizer, boiler drum and superheater. A high-pressure boiler feed pump can provide water to avenge at pressure higher than 100 bar then deliver it into the extreme conditions of boilers. This is important in power plants, where a relatively modest decline in water pressure could result in lower steam production — and thus reduced electricity output with greater operational expenses.

Performance must be consistent and high-efficiency in large-scale boiler systems such as those used for power plants or industrial manufacturing. The most powerful, energy-efficient three-phase motors are IE3-rated to meet the horsepower demanded during continuous duty cycles. For a 24/7 operation, this battery of motors would add up to be in service for an astonishing eight thousand seven hundred and sixty hours each year without much degradation taking place so that the boiler feed system is able to operate reliably. And this level of dependability minimizes the chances you will suffer through expensive downtime or emergency repairs.

“Where every horsepower really matters, you need motors that don’t just work — they have to be superior”, said Robert Hughes, Senior power plant engineer. This sentiment explains why a growing number of industrial plants are in the process to move towards ultra-high-efficiency motors such as IE3 series. High efficiency ratings—10-15% more efficient than standard-efficiency models—for the electric motors are designed to provide constant torque needed for pushing water at high head pressures and better optimize energy consumption. This leads to reduced energy bills and lower carbon footprints from your business, which is a win-win situation both economically as well environmentally.

Without it, maintaining a regular water supply at the desired pressure is not possible in high demand sectors employed by boilers that can consume up to 10,000 litres of waters for an hour. These motors help them deliver the required volume of water without overloading to run even at peak loads. This in turn reduces the wear and tear on your pump over time, which can make it last longer without needing more expensive repairs or a replacement.

You can use these pumps for boiling feed which itself incurs a lot of thermal stress, if the hot water will be stored at some elevated levels. IE series motors, renowned for their excellent thermal stability are all capable of operating up to 80°C without running the risk of overheating and losing efficiency. This is especially important in boiler systems where water temperatures can exceed 150 degrees Celsius, and the equipment must be able to perform as designed at that temperature.

Reduced Operational Costs is Another Big Reason to Employ IE3 Motors in Boiler Feed Pumps Energy often represents a significant part of operational budgets in many industries, so switching to high-efficiency motors can provide large savings for companies. On a non-HPC plant, annual electricity savings for the typical industrial boiler system might be around $5–10k per year once optimised IE3 motors are in place to meet running duties.

Booster Pumps in Water Pressure Systems

In both residential as in industrial buildings, booster pumps are very important for giving to the necessary pressure so that there is constant flow of water gets maintained. These include high-pressure building water networks, as well systems in large industrial or commercial facilities that need to deliver a consistent pressure across an extensive piping network. A vertical booster pump will have a maximum capacity of 10 bar per stage which is more suitable for buildings that are taller and with multiple floors.

Many residential buildings taller than 30 meters experience inadequate water pressure, particularly in the higher parts of the building. This is the reason a booster pump with an IE series motor can easily resolve this issue by providing water at 50% more pressure than normal pumps. That provided level of performance that ensures tenants on the highest floors have more than enough pressure to get a good shower, rinse dishes in kitchens and other daily life uses.

For industry applications such as high volume and pressure water needs, horizontal booster pumps with IE3 motors work well. These motors power pumps capable of handling up to 500 m³/h, keeping the factories, warehouses and production sites turning over. IE3 motors are up to 15% more energy-efficient, which makes them the right choice for any company in need of increasing performance while reducing cost.

“Water pressure is simply an impermissible area to allow any kind of cutback within,” advises Sarah Johnson, PE as well. In commercial buildings, for example, a pump failure can make life difficult to hundreds of people/day so reliability is key. This is where IE-Series engines come into their own. The motors are engineered to operate nonstop for long periods so the water pressure does not drop intermittently. In fact, with high efficiency motors many companies report operational uptimes of 99% or greater.

Booster pumps will also assist in coordinating water delivery from huge systems, such as industrial complexes or entire municipal setups. In such applications, the horizontal booster pump combined with IE series motors give power needed as well work long lasting for high efficient working conditions. The motors feature an automatic adaptation of the output to load for variable water demand, making them ideal low energy consumption products.

Maintaining an acceptable level of performance down to 5°C is important in order for motor drivers and pumps to function properly; they have been designed with industrial applications where water temperatures typically range from that can reach up to ~90°C., The Tentatek IE series motors are built to maintain peak efficiency regardless of the temperature conditions making it far more reliable under all scenarios. This is important in applications such as food processing or chemical facilities that require specific water temperature and pressure ranges for production requirements.

For overall cost effectiveness, the use of an IE3 motor with a booster pump would save loads. For instance, the installation of an IE3 Motor powered booster panel will save up to $2000-$3000 per year in a mid-sized commercial building. Over a five-year period, this can mean significant overall savings in which an investment for these premium motor becomes justified.

Fire Pumps in High-Pressure Emergency Systems

The fire pump is the very heart of a commercial or industrial complex that builds fired protection there to offer. The pumps provide high-pressure water to sprinkler systems, fire hoses, and other firefighting tools during a blaze. Centrifugal fire pump — With a flow rate of up to 2,000 gallons per minute (GPM), it’s no surprise that you will find this type large buildings as they are integral in controlling the inevitable infernos. From a multi-story office building to an industrial plant, knowing you have dependable access to high-pressure water is absolutely essential.

The firefighting systems require very fast response where IE series motors supports well. They are so built to start instantly and attain full power within seconds, making them ideal for ensuring water is delivered at great pressure urgently in fire pumps. A typical example is a centrifugal fire pump powered by an IE3 motor that reaches full flow in <10 s for immediate emergency protection, as illustrated. In a world where time is of the essence, this type of rapid dispersal can mean the difference between an efficient fire alert and disaster.

John Carter, a fire systems safety consultant adds his perspective: “A fire pump is no better than the motor driving it.” He stresses that reliability is the most important attribute when it comes to fire safety equipment. IE series motors feature both high output power and temperature resistance under harsher conditions; if a fire is burning, it won’t melt! Traditionally, these motors are rated for continuous duty in harsh environments — which means the pump can supply water as much and often as it is called on to output.

Although, 5th-century people were just using the water wheel technology to empower their fire pumps that too without generating pressures up to and over than even reaching the required value of 150 PSI in high-rise buildings while miles of piping is there above ground level which needs best nutrients for mice. Such a demanding product can easily be handled otherwise by horizontal or vertical centrifugal pumps with IE series motor.newArrayList[ That means whether its 14,000 RPM props spinning at 30knts or loooow and slow to conserve battery life the top end of these motors is experienced activating for a fraction of your operation time in dewatering applications leaving the remainder all low power management.

Systems that need to be running all the time should also take care of its energy efficiency. IE3 motors can save up to 10-15 per cent of standby energy bill, which makes them viable in look term. This is especially advantageous for hospitals, hotels and other large office complexes which require fire safety systems to be constantly at the ready without eating up too much machinery power.

IE series motors are used to drive systems powered by jet pumps, which is responsible for creating waterflow (using the Venturi effect) in other parts of the engineering. Gravity pumps are also being used in places where water must be lifted from a great height or volume, like wells and sump waters. Meanwhile, a well-performing jet pump can lift water to 40 meters which means you will have firefighting potential in even complicated places.

Durability is another hallmark of IE series motors. Pumps: In most fire systems, years – even decades – can pass before pumps and motors are actually needed. IE3 motors are constructed from the best materials available featuring an outer coating that goes about preventing corrosion, reducing wear and extending service life. The tests have proven that the same engine can function for more than 20 years while requiring only a minimum of maintenance, which should provide reassurance to building owners.

Efficient IE3 motors mean these fire systems can save on overall lifetime running costs, and expected increases in service cylinder life. Energy saving on the order of $5000 per year is not uncommon for big facilities utilizing more older, less efficient motor models.