Three-phase motors have several advantages in industrial applications, including an average service life of 15 to 20 years, which is 50% longer than that of single-phase motors. With their high starting torque and efficiency, they can reduce energy consumption by up to 30%, which cuts maintenance costs and saves more than 1 million yuan every year in equipment maintenance expenses.

Stable Performance, Reducing Equipment Failures

The stability of three-phase motors significantly contributes to improving the efficiency of industrial production, especially during long-term, high-load operations. Statistics show that the average failure rate of three-phase motors can drop below 1%, whereas the failure rate of typical single-phase motors is usually over 5%. This not only affects production costs but also effectively reduces downtime and equipment maintenance expenses.

Most enterprises using three-phase motors prefer products with higher efficiency classes, such as IE3 or IE4. Such motors can operate stably with about 30% less current fluctuation compared to traditional motors, preventing overheating or damage due to unsteady currents during long-term operation. Most high-intensity industrial productions, including steel and chemical industries, use three-phase motors to ensure the safety and stability of equipment under high-load conditions. Because of their high starting torque, three-phase motors can stably handle instant impact loads when starting large equipment without causing immediate damage. Single-phase motors usually experience significant current impacts at startup, which may lead to wear in circuits and components, further increasing the possibility of equipment failure.

Smooth Start, Improving Production Efficiency

The startup performance of three-phase motors is incomparably better than that of single-phase motors. They can provide greater starting torque, maintaining high reliability even under heavily loaded conditions with frequent starts and stops. The three-phase motor generally possesses a starting torque of about 1.5 to 2 times the rated value, while that of a single-phase motor usually reaches only 0.5 to 1 times the rated torque. When large equipment requires frequent starts, three-phase motors can effectively avoid startup shocks, reduce equipment wear, and prolong the equipment’s service life.

Three-phase motors have shorter startup times and can reach rated speed quickly, which is very important for raising production efficiency. For a high-efficiency production line, every 1-second reduction in startup time can increase annual production efficiency by 2%-3%. In industries requiring high-speed production, such as food processing and textile dyeing, the advantages of three-phase motors are more prominent; therefore, they give priority to three-phase motors. Smooth startup provides better equipment safety and reduces the stress of current surges on the power grid, thus minimizing power losses during peak electricity usage. According to statistics, companies using three-phase motors can save an average of 10% on electricity costs, which is significant for high-energy-consuming factories.

Long Lifespan, Low Maintenance Costs

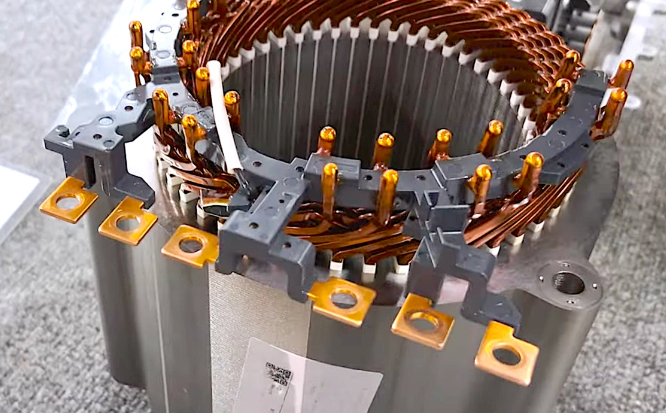

Three-phase motors perform exceptionally well in industrial applications, particularly regarding lifespan and maintenance costs. Typically, three-phase motors have an average lifespan of around 15 to 20 years, while similar single-phase motors last only about 10 years. This means that within the same production cycle, companies using three-phase motors do not need to replace their equipment frequently, significantly reducing equipment purchase frequency and overall losses caused by downtime. They also have fewer structural parts than single-phase motors, with no complex starting capacitors or auxiliary windings; thus, they generate less internal wear. In this respect, the bearing and insulation systems of a three-phase motor last 30%-50% longer compared to those of single-phase motors.

A company manufacturing heavy machinery decided to replace the conventional single-phase motors in some equipment upgrades with three-phase motors. Within three years, it reduced equipment maintenance costs by around 40% and the number of motor replacements by more than half. On-site data from these projects reflect the economic benefits of three-phase motors in long-term operation: good heat dissipation performance reduces operational temperature and prolongs service life. For every 10°C reduction in the internal temperature of the motor, the service life of the equipment is doubled. Moreover, choosing three-phase motors will effectively avoid high-temperature problems that lead to aging and damage in factories operating in such environments, hence mitigating unexpected downtime.