The type of a three-phase motor depends on factors like rotor type, speed, and load. For example, a 50 Hz, 4-pole motor achieves 1500 RPM, ideal for conveyors. A 200 kW motor with 300% starting torque suits crushers.

Rotor Type

The type of rotor used in a three-phase motor significantly influences its functionality and suitability for various applications. Squirrel cage and wound rotor designs dominate the market, each offering specific advantages depending on the operational demands. In going into the specifics of these types, strengths are revealed with precise data and examples.

Squirrel cage rotors have a very simple design and hence are highly efficient; these are commonly used in industrial and commercial applications. These rotors can realize efficiencies within the range of 85% to 98% depending on the size and class of the motor. In this view, a squirrel cage motor running at 96% efficiency in a 15 kW industrial fan application saves about 400 kWh annually compared to a motor operating at an efficiency of 92%. This efficiency translates into a cost saving of about $40 annually at an average energy price of $0.10/kWh. Squirrel cage motors handle high workloads reliably, often operating for over 30,000 hours between major overhauls. They are commonly found in conveyor systems, compressors, and HVAC equipment, which all demand consistent performance and have minimal downtime.

Wound rotor motors offer greater control over torque and speed, making them ideal for heavy-duty applications. These motors can achieve starting torque levels exceeding 200% of the rated torque, which becomes essential in operations like cement mills or crushers that require high initial torque. As a matter of fact, in the mining industry, a 200 kW wound rotor motor is capable of smoothly adjusting torque for lifting heavy loads with ease; this ensures smooth operation and reduces mechanical stress. Although these motors typically operate at a bit lower efficiencies—94% to 96%—the capability for dynamic adjustment of performance balances the difference in efficiency for applications with variable speed requirements.

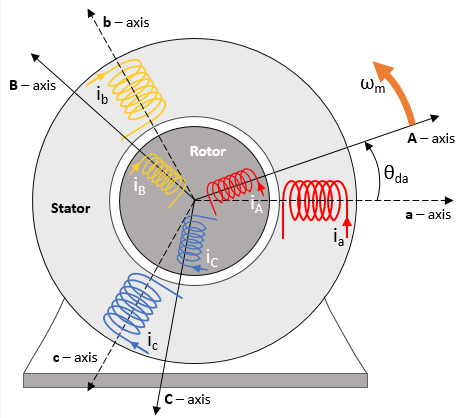

Speed and Pole Count

The speed and number of poles are two critical factors that define the performance, efficiency, and application of a three-phase motor. The relationship between these two aspects is defined by the synchronous speed formula: Ns = 120×f/P, where Ns is the synchronous speed in revolutions per minute (RPM), f is the supply frequency in hertz (Hz), and P is the number of poles. From this formula, it can be seen that the number of poles inversely influences the speed of the motor, and hence, the number of poles is an important factor when choosing a motor for certain requirements.

In applications requiring high speeds, two-pole motors are used. At a normal frequency of 50 Hz, the synchronous speed, in such cases, is 3000 RPM, while for 60 Hz, the speed is 3600 RPM. These motors are suitable for pumps, compressors, and fans since their application requires high-rotational speeds. As an example, a centrifugal pump that requires 75 kW of power output and runs at 3500 RPM would work effectively with a two-pole induction motor driving it. A typical efficiency rating for these kinds of motors is in the range of 90 to 95%, with designs to support continuous operation under minimum losses. This high speed further enables these motors to provide power density, reducing the physical size of the motor and optimizing the compact setup of space effectively.

Four-pole motors have synchronous speeds of 1500 RPM at 50 Hz or 1800 RPM at 60 Hz and are used in medium-speed applications such as conveyor belts, mixers, and general machinery in industries. The same 50 kW four-pole motor, for instance, can move material on a conveyor belt at 1.5 meters per second, maintaining a continuous movement of goods. Four-pole motors give far smoother operation and less vibration than two-pole motors, therefore extending the life of the motor and reducing maintenance costs. They normally obtain efficiency ratings between 88% to 93%, so they are generally quite reliable yet affordable for extended operation.

It is not unusual for six-pole, and sometimes eight-pole motors to be used in low-speed applications, running at 1000 RPM and 750 RPM respectively at 50 Hz. This type of motor serves many heavy power applications such as in crushers, hoists, and large industrial fans. For example, a 150 kW six-pole motor driving a crusher could easily develop a torque high enough to crush more than 200 tons per hour of material. The lower speed of these motors reduces vibration and minimizes mechanical wear, which provides higher reliability. The disadvantage of such motors is size and weight, which are larger than higher-speed motors due to the use of more material to build additional poles. The efficiency ratings for six-pole motors are from 85 to 90% because of the loss caused by the increased amount of electrical windings.

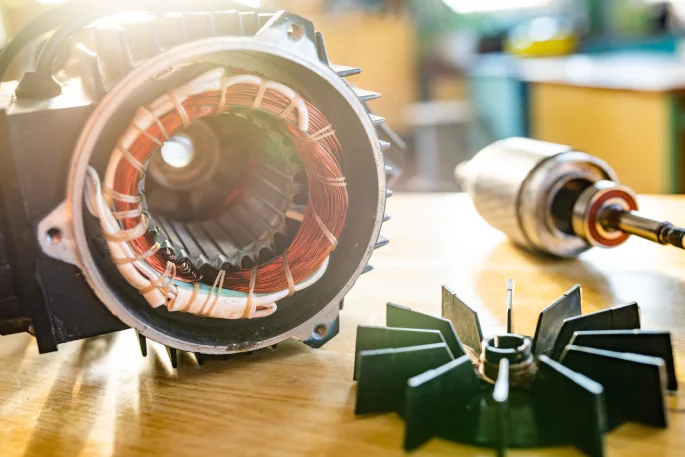

Construction

The construction of a three-phase induction motor forms the very basis of its durability, efficiency, and suitability for an operating environment. The type of motor enclosure, cooling mechanism, and material choice all combine to define the performance of the motor under specific conditions. It is important to understand construction to optimize the motor for the application it will serve.

Some of the most common types of motors used in an industry are Totally Enclosed Fan-Cooled (TEFC) motors. These motors prevent dust, dirt, and moisture from ingressing, and therefore, are able to operate in quite harsh environments. For example, a 75 kW TEFC motor would serve efficiently in a manufacturing plant running at full load for 16 hours per day continuously at an efficiency as high as 95% with minimal energy consumption. With an average life rating of over 50,000 hours, these are extremely effective TEFC motors in industries like mining due to the constant threat of dust and debris. These motors have a separate fan that circulates air over the enclosure to ensure proper heat dissipation and adequate operation in high ambient temperatures of up to 50°C.

In contrast to this, ODP motors are designed for application in a clean, indoor environment. In their construction, they have openings for ventilation that provide them with efficient air cooling and hence higher thermal efficiency compared to enclosed motors. An example could be a 100 kW ODP motor running at an efficiency of 92% that would dissipate heat much more effectively than its comparable TEFC motor operating under the same conditions, which may require some additional cooling externally. However, without this protection from the external environment, ODP motors are generally relegated to duty in controlled environments—such as HVAC systems or machinery that is also housed in a clean industrial building. ODP motors are lighter and typically cost about 15% to 20% less than comparable horsepower-rated TEFC motors, which makes them an economical choice when suited to the application.

Explosion-proof motors are a necessity in hazardous areas where concentrations of flammable gases or dust may exist. These motors have heavy-duty housings that can contain any explosion that may originate inside the motor and prevent it from propagating to the outside atmosphere. A typical example of an explosion-proof motor is a 200 kW motor applied in an oil refinery to drive pumps that transfer volatile chemicals. In fact, such motors are certified for respective hazardous zones and are designed to operate safely even in an atmosphere containing up to 5% methane. These added safety features increase the motor’s weight and cost. An explosion-proof motor may be 25 to 40% more expensive than a standard TEFC motor of the same capacity, but the cost is justified in view of the risk that it mitigates.

Starting Method

The starting method of a three-phase motor is crucial for its operation, mainly from the viewpoint of torque, current draw, and application needs. Various starting methods are employed, based on the size of the motor, the load condition, and the electrical infrastructure. Each of these methods has advantages, limitations, and cost implications; hence, the selection will be important to optimize the performance.

DOL starting is the simplest and most commonly used method for small motors, typically up to 5 kW. The motor in this method is directly connected to the power supply. This results in a high inrush current into the motor, normally 6 to 8 times the full-load current. Assuming a 3 kW motor with full-load current of 6 amps, it may draw as high as 48 amps on startup. The method is cheap, since it needs just a few extra chips, but the high value of starting current could cause voltage dips in a weak electrical system. Despite this fact, DOL starting is ideal for applications such as small fans, compressors, and pumps, where the motor is to start with no load or light load conditions.

Star-Delta starting is normally applicable to larger motors in the range of 5 kW to 50 kW with the object of reducing the starting current. During this type of starting method, the motor starts in a star configuration where each phase receives a lower voltage, 58% of the line voltages, which reduces the starting current to about one-third of that obtained with the DOL method. After the motor attains a stable speed, it switches to a delta configuration for its normal operation. An example would be that a 30 kW motor with a full-load current of 50 amps would need only about 100 amps during startup, while in DOL starting, it would require about 300 amps. This reduction then minimizes stress on the power supply and becomes very advantageous for systems with limited electrical capacity, such as factories or large commercial buildings. This smaller impact means this additional cost could be warranted, typically in the range of $500 to $1,000 for a star-delta starter.

Soft starters are more advanced devices to limit inrush current and starting torque. Since they gradually ramp up the voltage to the motor, this allows the motor to have a soft and controlled acceleration. A soft starter has the ability to reduce inrush current as high as 70% depending on the settings and load on the motor. For instance, for a 75 kW motor, full-load current is 120 amps; it could draw only about 180 amps at startup instead of the usual 720 amps during DOL starting. This reduction extends the life of the motor and attached mechanical parts, such as belts or gearboxes. While soft starters tend to be more expensive, in the range of $1,500 to $3,000 for motors of the mid-size categories, their application areas include water pumping stations and conveyor systems, where variable control is crucial.

Voltage and Frequency

Voltage and frequency are two critical parameters of a three-phase motor that will determine its performance, efficiency, and compatibility with power systems. Different regions and applications require the design of motors for specific voltage and frequency standards, which directly influence their operational capabilities and cost-effectiveness.

Most industrial and commercial three-phase motors are designed to work with standard voltages like 380V, 400V, or 480V in different parts of the world. For example, the standard for motors in Europe is 400V at 50 Hz, whereas in North America, it is 480V at 60 Hz. The difference in frequency gives a different synchronous speed. A two-pole motor operating at 50 Hz is running at a synchronous speed of 3000 RPM, but an identical motor at 60 Hz would be running at 3600 RPM. This means that 60 Hz systems can be used advantageously for applications that require high speed, such as compressors or fans. In contrast, 50 Hz applications could be advantageous where the speed is lower and will not create so much wear and tear, such as conveyor belts or crushers.

Voltage levels also influence motor size and efficiency. A 50 kW motor designed for 480V typically has an operating efficiency of 95% at full load, while the same motor designed for 400V might achieve slightly lower efficiency due to increased losses. Also, motors designed for lower voltages—e.g., 220V—extract higher currents to provide the same power. For instance, the 10 kW motor on a 220V supply would pull around 45 amps, whereas the same motor on 400V would pull just 25 amps. This increased current in low-voltage systems increases resistive losses, thereby decreasing overall system efficiency. Therefore, the proper choice of voltage is essential in order to achieve maximum energy usage with reduced heat dissipation in electrical systems.

Frequency is a critical determinant of both motor torque and power output. For instance, at the same voltage, a motor that has been designed for 50 Hz will give a somewhat higher torque than a similar motor designed for 60 Hz since, due to the lower synchronous speed, it can have a larger diameter rotor or additional poles. For instance, a 200 kW motor operating at a frequency of 50 Hz might develop a starting torque of 300% of rated torque, while the same motor at 60 Hz might achieve 250% due to higher speed. However, the increased power at 60 Hz can be advantageous for applications requiring high energy density, such as industrial pumps or turbines. These differences underline the need for choosing, with respect to a specific application, the motor that has the proper frequency.

Application Requirements

The design, size, efficiency, and operational characteristics of a three-phase motor are derived from its application requirements. These factors also define the suitability of the motor in specific tasks and environments on energy consumption, performance, and lifespan. Matching a motor to its application ensures optimality in functionality and cost.

Applications requiring constant torque, such as conveyor belts, mixers, and extruders, use a motor whose torque should be kept constant over an irrational speed range. For example, a conveyor carrying 10 tons per hour requires a 15 kW motor rated for continuous operation in terms of torque rating. Motors on these applications are usually in the range of 90 to 95% efficient at full load. Proper sizing of the power and speed rating minimizes mechanical stress and prevents overheating. For instance, using a motor rated at 11 kW instead of the required 15 kW might save upfront costs, but it would lead to excessive wear, higher maintenance costs, and reduced efficiency.

Variable torque applications, such as fans and pumps, require motors capable of adjusting torque as speed changes. For instance, a 50 kW motor driving a centrifugal pump could save substantial energy if a VFD is installed on the motor. In general, the power requirement of a pump or fan varies with the cube of the speed. If the motor speed is reduced by 20%, the energy saved is approximately 50%. A given fan system may consume 40,000 kWh per year and, through appropriate selection of motors and VFDs, have an updated system consuming 20,000 kWh per year, thereby saving $2,000 per year at an energy cost of $0.10/kWh.

Constant power applications include those involving grinding mills, lathes, or machine tools, which require motors that deliver constant power across a range of speeds. A grinding mill that requires 100 kW at 500 RPM would require the same power at 1,000 RPM, but the torque would be reduced by half. Motors used in these applications are often equipped with heavy-duty cooling to operate for extended periods. Although an initial cost of a motor with a constant power drive system may be higher by 30% over a standard one, the enhanced performance and reliability make it a necessary investment in such precision tasks.

Load Characteristics

The load characteristics of a three-phase motor significantly influence its design, efficiency, and performance. Understanding whether the application involves constant torque, variable torque, or constant power loads is essential for selecting the right motor and ensuring operational success. These characteristics directly impact energy consumption, mechanical stress, and motor lifespan.

Constant torque loads require motors that deliver a steady amount of torque regardless of speed. In general, conveyor belts, extruders, and compressors are just a few examples of such applications. Assume a conveyor belt moves 20 tons/hr, and the application requires a motor that can supply 50 Nm of torque across the entire operational speed range. In this case, a 15 kW motor would use roughly 13.6 kW of energy in steady-state operation at 95% efficiency to meet the requirements of such operation and provides reliable service with minimum energy cost. Most of the motors for constant torque loads are designed in such a manner that they possess sturdy frames and cooling systems to bear continuous use without overheating or any loss in efficiency.

Variable torque loads include applications such as fans and pumps, where the torque requirement varies with speed, usually being proportional to speed squared or cubed, respectively. In a typical centrifugal pump system, a 50% reduction in motor speed can cut the power requirement by as much as 87.5%. Using a 100 kW motor at full speed might result in an annual power consumption of 80,000 kWh. Using a variable frequency drive to reduce motor speed by 20% can save up to 20,000 kWh a year, thus slashing energy costs by as much as $2,000 if electricity costs $0.10 per kWh. This characteristic makes variable torque motors most suitable for energy-saving applications, especially in HVAC systems and water treatment plants.

Constant power loads are those that use motors with a constant power output at different speeds. The industrial applications include lathes, grinders, and winders. For example, a grinding mill that needs 200 kW at 1,000 RPM would need exactly the same power when running at 2,000 RPM, though the torque requirement is inversely proportional to the speed. Motors designed for constant power loads often include specialized cooling mechanisms, as they tend to generate more heat during operation. Because of additional design complexity, the cost of a constant power motor is usually about 20% higher than standard motors, but the investment covers your demands for precision and reliability in critical applications.