Three-phase motors have balanced currents to generate power with an efficiency of more than 90%. They generate a stable output through a phase difference of 120 degrees between each phase; therefore, they minimize equipment wear and increase their life. Fast responses to changing loads with less than 0.5-second recovery assure efficient system operation.

Table of Contents

ToggleImportance of Three-Phase Motors in Power Generation for Efficiency Improvement

Three-phase motors can play an important role in power generation, directly determining the operation effectiveness and economic performance of the power systems. On an industrial scale, the generation usually achieves more than 95% by three-phase motors; thus, it is widely used in many power plants and major industrial-scale generation stations. Three-phase motors offer stable power output with high controllability. Standard industrial three-phase motors range from 10 kW to 500 kW, and compared with the single-phase motor systems, in three-phase motors, the current loads are handled more evenly, reducing equipment wear due to fluctuations in current and extending the overall lifespan both of the motor and the power generation equipment.

Three-phase motors perform excellent in electrical energy conversion, typically reaching speeds of 1500 RPM or higher. This, in turn, provides high torque output, and it enables the power generation equipment to work stably under high load with no overheating issues. Three-phase motors also have low starting current, low energy consumption in a start-up manner and full power assurance of power output. These technical features, on the one hand, reduce energy loss in power generation for power generation enterprises. On the other hand, it elevates the entire stability of power production. This not only can achieve long-time high efficiency in running but also effectively reduces operating costs by providing safety in power output.

Three-Phase Motors and the Stability in Power Output

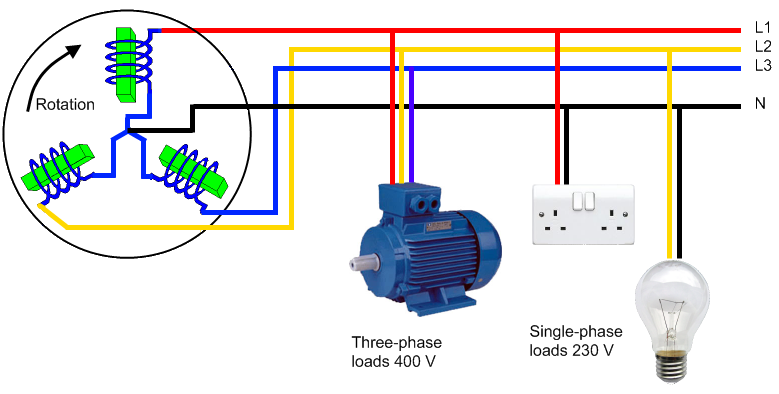

These three-phase motors are continuous in their generation, with highly stable power output, which, in turn, makes the process highly stable. The power industry relies on three-phase motors since their three-phase AC output maintains a phase difference of 120 degrees between each phase to allow smooth flow without any disturbance in current and hence avoid current fluctuation problems associated with single-phase motors.

Compared to single-phase motors, three-phase motors have advantages in power output. The 400-volt, 50 Hz industrial three-phase motor can maintain a stable current for a long time when it operates under full load with a strong load capability. In such cases, this kind of three-phase motor is able to control voltage output fluctuations within ±5%, adapting to various power grid conditions. Due to its stability, power generation companies all use this three-phase motor in large power generation machinery in order to ensure that the power transmission will be stable.

In specific power generation applications, motors can employ synchronous or asynchronous modes for a three-phase motor. Both types have their characteristic features, but all can realize high precision in current control. Synchronous three-phase motors rely on the synchronization of rotor speed with grid frequency to provide stable torque output, and this will be suitable for application scenarios like wind power generation. This is in comparison to asynchronous motors, which are more flexible and whose output changes with any load change, hence suitable for all power generation systems where the load fluctuates. It means that the design will also ensure not only optimum power but also resilience at the grid. The three-phase motors can also provide a high level of reliability in power systems to withstand voltage fluctuations of about 15% in the short term without hindering the quality of the power output.

Three-Phase Motors Play an Important Role in Current Balance

Three-phase motors are at the core position of the current balance, and their operation directly influences the stability of the power generation systems. In the design of this three-phase system, a phase difference of 120 degrees is kept between each phase to ensure that the current is balanced while the motors are working. Such a design effectively avoids instantaneous current fluctuations and reduces the impact of asymmetrical current on the equipment of power generation; hence, the whole generating process becomes highly efficient and safe.

In the power industry, the current balance is an important factor affecting equipment life and maintenance costs. Unbalanced current may raise the temperature of a motor by 15-20%, which further cuts down the life of equipment and increases maintenance costs. Three-phase motors guarantee stable current balance, directly reducing this temperature increase to protect and extend equipment lifespan. With such current balance characteristics, three-phase motors are widely used in various power generation scenarios, especially for high-power output environments. A report from the German Energy Association estimated that a three-phase motor balance can increase wind power generation efficiency by about 12%. This is important for renewable energy generation since it increases the rate at which clean energy is utilized, hence decreasing the overall energy cost.

The quality of the power output is also influenced directly by the current balance in the power generation system. While keeping the current balance intact, three-phase motors resist load fluctuations efficiently. Current face a rapid increase or decrease in case of a sudden change in loads, thus keeping the output current stable. For instance, a nuclear power plant in France has three-phase motors that retain up to 99% current balance, even in the fluctuation of over 20% in the load, and have maintained the power transmission fluctuations within safe limits. With such stable current output, safe grid operation is ensured with reduced risks of faults due to current imbalance.

Three-Phase Motors for Protection in Power-Generating Equipments

The three-phase motors are very important to protect power generation equipment. These motors have a high level of efficiency power output and maintain current stably. The three-phase motors support the continuous operation of power generation equipment under the conditions of fluctuating load in various situations. Moreover, in power generation equipment, three-phase motors effectively reduce the current asymmetry due to equal distribution of current. Since current asymmetry commonly causes overheating of equipment and even destruction, these motors will effectively avoid these disadvantages, prolong service life, and reduce maintenance time for power generation equipment.

Three-phase motors have a wide application in modern power plants and have proved to be considerably adaptable to loads. In case of big fluctuation in load, the motor can perform fast adjustment of its output and recover current stability within 0.5 seconds to avoid equipment failure due to current fluctuations. Three-phase motors provide highly reliable operation not only in daily use but even under extremely bad environments. For photovoltaic power plants set up in deserts, the three-phase motors are high-temperature tolerant and do not show any defects under sand, acting normally until the temperature goes up to 50 degrees centigrade, while the average service life has reached as high as up to 20 years.