Wear insulated gloves and protective goggles, and check the wiring for tightness. A multimeter can be used to measure the resistance, which should be less than 0.5 ohms. Cut off the power supply for at least 5 minutes before performing maintenance to avoid the risk of electric shock.

Table of Contents

ToggleProper Wearing of Personal Protective Equipment

Proper wearing of personal protective equipment is a necessity when operating a three-phase motor. It minimizes the chances of accidents and ensures the operator’s safety in critical situations. Insulated gloves should always be worn. OSHA requires that operators use insulated gloves while operating in any place with a voltage greater than 50 volts. Generally, the voltage of three-phase motors is higher than 380 volts, so wearing insulated gloves can prevent electric shock. High-quality insulated gloves on the market range from $50 to $100. The cost is relatively low while they provide critical safety protection.

Besides gloves, insulated shoes are necessary equipment. Many motors are installed in environments where water or metal shavings may be present on the ground, providing conductive material. Electric shock accidents due to contact with conductive ground can be effectively avoided by wearing insulated shoes meeting ASTM standards. The selection of face shields and goggles becomes very important as well. Sparks or spatters may be generated when the motor is started up and operating, in which case the eyes and face of an operator may be injured. According to the standard ANSI Z87.1, goggles and face shields are effective against these potential hazards. In fact, more than 30% of all accidents involving motors harm the eyes through spatters whenever goggles are not worn. Noise-canceling earplugs or earmuffs are protective devices that are also necessary to protect one’s ears. For most high-power three-phase motors, the noise levels are higher than 85 decibels. Long-term exposure to high-noise environments could lead to hearing loss and may also cause tinnitus problems in personnel. Using earplugs that meet the NRR standard can reduce noise by 20 to 30 decibels, hence greatly reducing the damages from noise to the hearing. Correctly wearing protective equipment is a concern not only of personal safety but also of professional ethics.

Inspecting Motor Wiring Before Startup

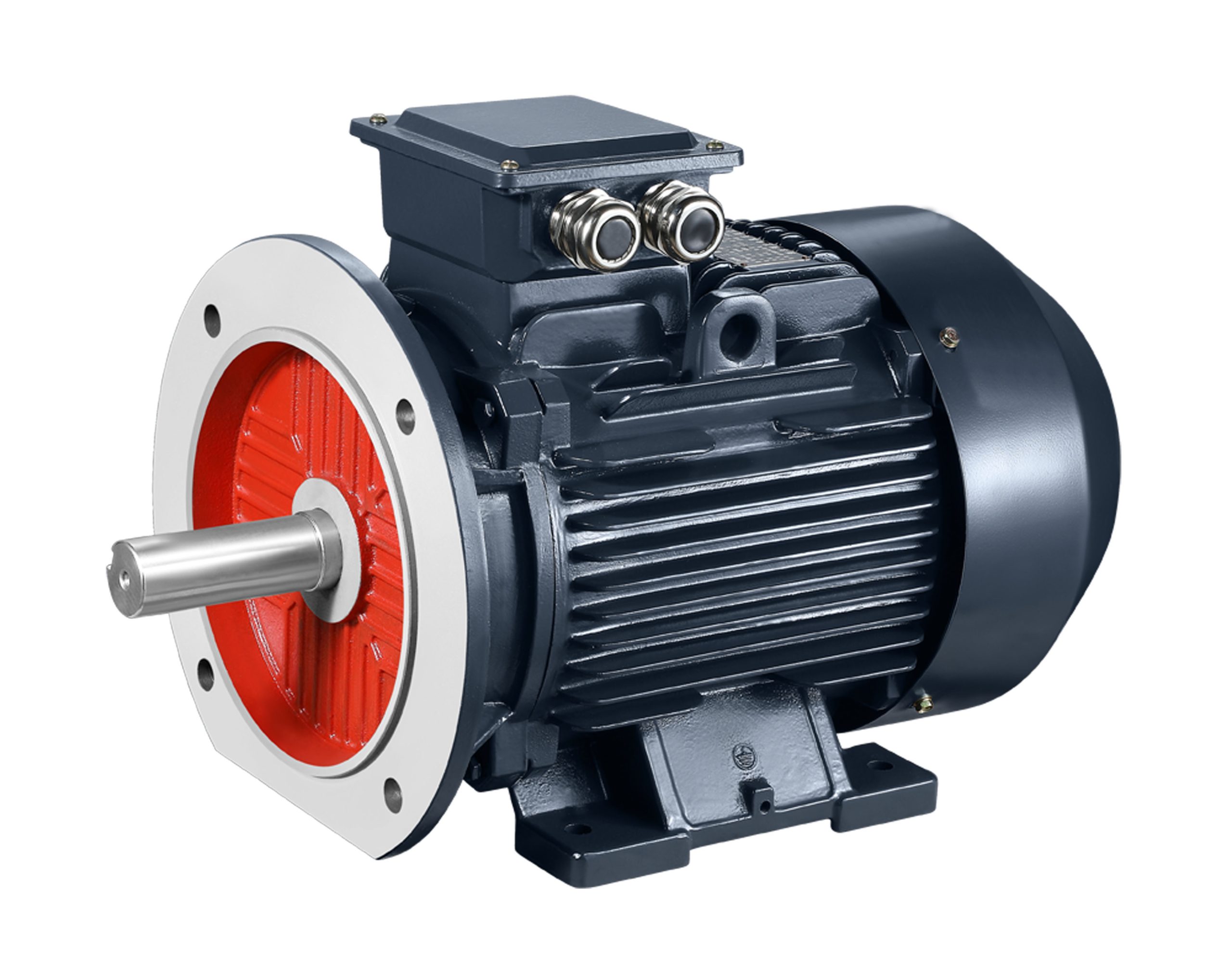

Inspecting the motor wiring before startup is the first step toward ensuring safety and correct operation of machinery. Several of the more common wiring methods for three-phase motors include Y connection and Δ connection. Different wiring methods will directly influence the startup characteristics and operating efficiency of motors. The Y-connection, for example, reduces the voltage to 57.7% of the rated value when starting, thereby effectively reducing the starting current and enabling operation under heavy loads. According to the IEC, each wire should have a resistance value not exceeding 0.5 ohms; otherwise, the motor may operate unstably or even result in a short circuit. By inspecting the wiring, a multimeter can be used to measure the resistance of each wire to ensure it falls within the standard range. If some of the wires have a very high resistance value, then there may be a problem with poor connectivity or aging in that wire, which must be replaced or repaired immediately.

Another important inspection point is the tightness of the wire terminals themselves. The vibration during long-term operation of a motor can cause wire terminals to loosen, leading to a short circuit or sparks. More than 20% of all industrial fires are caused by electrical fires due to loose wiring. Use a torque wrench to check each wire terminal for tightness, making sure the values meet the manufacturer’s recommended torque values. If a wire terminal cannot be tightened, it needs to be replaced or the head of the wire needs to be inspected. A grounding wire connection directly affects a motor’s safety performance. Grounding wires effectively guide leakage current to the ground to avoid electric shock to the operator. Its resistance should be less than 4 ohms, and an optimal value less than 1 ohm is preferred. To test the grounding system, a ground resistance tester can be used to make sure that the resistance from the equipment frame back to ground is within safety requirements. In addition, selecting the appropriate cable cross-section for various power levels of three-phase motors is very important. For instance, a 15 kW motor has a rated current of approximately 30 amperes, and the cable cross-section should not be less than 6 square millimeters. If the cable cross-section is too small, it would cause overheating of the cable, aging of the insulation, and could result in a fire. During wiring checks, refer first to the motor’s power parameters and use cables meeting the specifications based on them.

Perform Maintenance Only After Power Is Cut Off

In three-phase motor maintenance, the first thing to do is ensure that the power is fully cut off. This is a primary principle to avoid serious personal injury and equipment damage. The NEC requires that every power switch must be turned off before any maintenance operation can start; LOTO devices must be applied to prevent accidental operation. This rule is not only imposed within the United States but has also become a global benchmark for industrial electrical practices. More than 35% of all electrical accidents result from maintenance performed without the power cut off. In such cases, residual voltages inside the motor can rise as high as hundreds of volts, enough to cause fatal injury. For that reason, make sure that the motor is fully disconnected from the power supply, and verify with a multimeter that the voltage is zero before any maintenance work starts.

It is of prime importance—after the power cut—to wait for complete dissipation of the energy stored inside the motor. Some high-power motors use capacitors and other energy storage elements that can maintain high voltage for a short period even after the power has been cut off. Allow the motor to rest for at least 5 minutes after cutting off power to allow internal voltage to dissipate. Precautions during maintenance also have to be taken to ensure the supply does not reconnect inadvertently. Companies should put warning signs on the motor control panel and apply special power locks to lock the power switch, preventing other personnel from mistakenly turning it on. According to OSHA statistics, accidents caused by accidental power reconnection during motor maintenance account for 15% of all industrial accidents. Companies that enforce a LOTO system have seen a reduction in accident rates of more than 90%. Furthermore, grounding operations during power-off maintenance are also important safety methods. During the operation of large three-phase motors, very strong electromagnetic induction is produced; even when power has been cut off, residual current inside the motor may threaten human safety. Therefore, connecting the motor terminals to the ground will effectively discharge this residual current. This is why many large manufacturing companies take precautions by using special grounding rods before any motor maintenance commences, just to make sure that no residual current remains inside the motor.