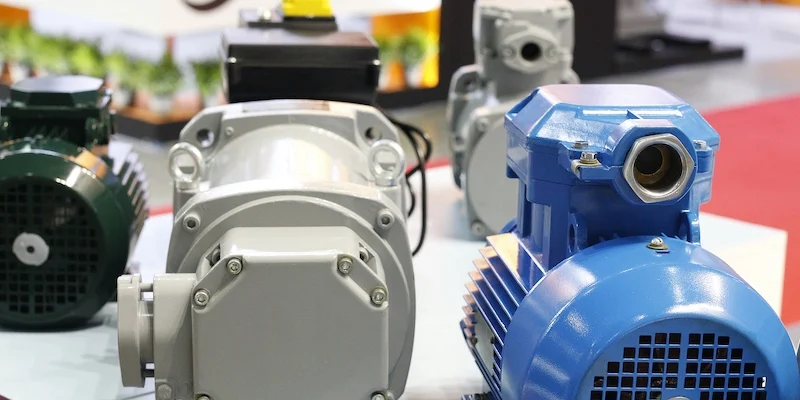

For a fan or pump of lower power rating (say from 0.5 – 3 kW), single-phase motors are to be used, which can achieve an efficiency of about 70%. 3000 kWh of electricity is roughly used by a 1kW single-phase motor operating for 3000 hours per year. Meanwhile, three-phase motors are good for industrial uses and can have power up to 100kW with an efficiency of around 90%. A three-phase motor of 15kW can save around 750 kWh of electricity during the same operating parameters. In simpler terms, single-phase motors are made for the household or small devices and three-phase motors are best when used in high-efficiency, running almost all day long, industrial applications.

Working Principle Comparison

Single-phase motors operate using single-phase AC electricity and are typically used in residential applications such as air conditioners or refrigerators. They are designed very straightforward and usually have a rotational speed of 1500-3000 RPM, which makes them perfect only for low load. Single-phase motors are generally suitable for devices under 1kW.

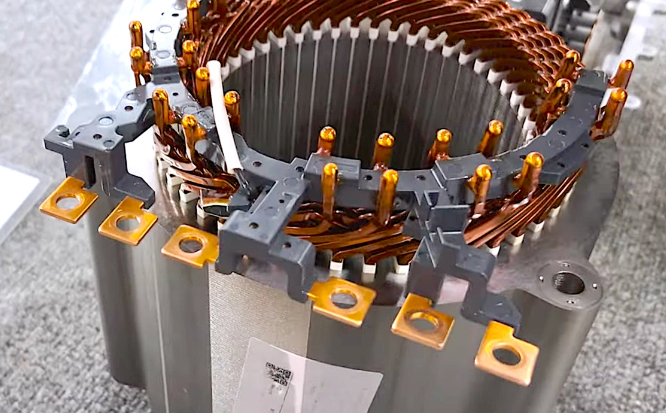

Three-phase motors, in turn, generate their rotating magnetic field with three sets of AC power, which is an easily predicted output torque, whereas rotational speeds are generally low. They could be from 750—3500 rpm and can be a solution to high-power industrial applications. At the other end of the spectrum, a regular three-phase motor will be able to handle up to 100kW of power, making it very useful for mass production.

Power and Efficiency

Single-phase motors have moderate power output (from 0.5 to 3 kW) and are mostly used for low-power households or small commercial equipment. Such an approach has low efficiency, usually around 70%, and results in more energy use over time. On average, a 1kW single-phase motor running for 3000 hours per year can consume nearly 3000 kWh of electricity.

Three-phase motors have an efficiency of generally around 85 to 95%, which means they are very energy-efficient, specifically for the longer-term running of large machinery. On an analogous operating condition, a three-phase motor with 90 percent efficiency and producing 15kW output power would save up to 750 kWh in electrical energy annually. High-efficient productions often rely on 3-phase motors to save energy, and many factories have employed three-phase motors in non-stop 24-hour daily operations to help the planet and their pockets.

Maintenance and Lifespan

One of the simplest types of motors around is the Single-phase Motor, and while its maintenance is easy, it may not be built to handle repeated starting and stopping. The general life expectancy is 10,000 to 15,000 hours for a single motor. But single-phase motors have lower starting torque, so when they turn on, there is a large current surge that wears out the internal components quickly.

Single-phase motors tend to be less stable and long-lasting compared to three-phase motor maintenance. This makes them unsuitable for continuous operation under harsh industrial conditions. In high-quality industrial three-phase motors, the motor life is generally 20,000 to 40,000 hours under different load conditions and working environments. Three-phase motors are designed to withstand the high-stress environment of industries like oil and gas and be run at capacity for years without regular maintenance.

Installation and Application Scenarios

Single-phase motors are easy to install and often used in areas with limited electrical infrastructure or single-phase power, like homes or small factories. Typically, they fuel the air conditioner, washing machine, and other appliances. In these cases, utilizing a three-phase motor would be necessary and inexpensive. Single-phase motor devices are said not to be capable of producing more than 5kW.

A three-phase power supply does not work with single-phase motors, and hence, their installation costs are higher due to the 3 phases. However, they are commonly employed in heavy industries and high-power equipment applications. Mining equipment, wind turbines, and BIG compressors all depend on 3-phase motors to work correctly. A 50kW three-phase motor can operate semi-continuously on an industrial production line over weeks or even months before it shows any appreciable drop in performance.

Cost and Value for Money

The price of a single-phase motor is usually much lower; a 1kW single-phase motor generally costs between 500-800 RMB, which is generally more cost-effective for users who have low requirements on the budget. This obviously has significant long-term usage costs, particularly for 24/7 operation where the higher energy consumption of a less efficient device combined with maintenance becomes an issue just as millions of users of single-phase motors are required to purchase annual maintenance costs of thousands (over 1000) in order to operate normally.

The initiative cost of a three-phase motor is high, and the quotation of a 10kW three-phase motor is between 3000-5000 RMB. Three-phase motors will have rated efficiency and life expectancy than single-phase and would be more economical over a longer period. A three-phase motor can thereby even be paid off for a few years by the electricity saved per year of approx. 1500 kWh/year compared to the corresponding standard product. Consequently, these single-phase motors are believed to be a better economic value for small equipment and three-phase motors for large-scale equipment under continuous use.

| Parameter | Single-phase Motor | Three-phase Motor |

|---|---|---|

| Power Range | 0.5-3kW | 10-100kW |

| Efficiency | 70% | 85%-95% |

| Annual Power Consumption (1kW) | 3000 kWh | 2250 kWh (15kW) |

| Lifespan | 10,000-15,000 hours | 20,000-40,000 hours |

| Initial Cost | 500-800 RMB (1kW) | 3000-5000 RMB (10kW) |

| Suitable Scenarios | Household appliances, small devices | Industrial equipment, large machinery |