Induction motors are practical due to their simple structure, stable operation, high efficiency, energy-saving characteristics, and low maintenance requirements, making them suitable for long-term continuous operation. Users only need to periodically clean the stator windings and inspect insulation performance, and using a variable frequency drive (VFD) can further optimize performance, reduce costs, and lower energy consumption.

Simple Design

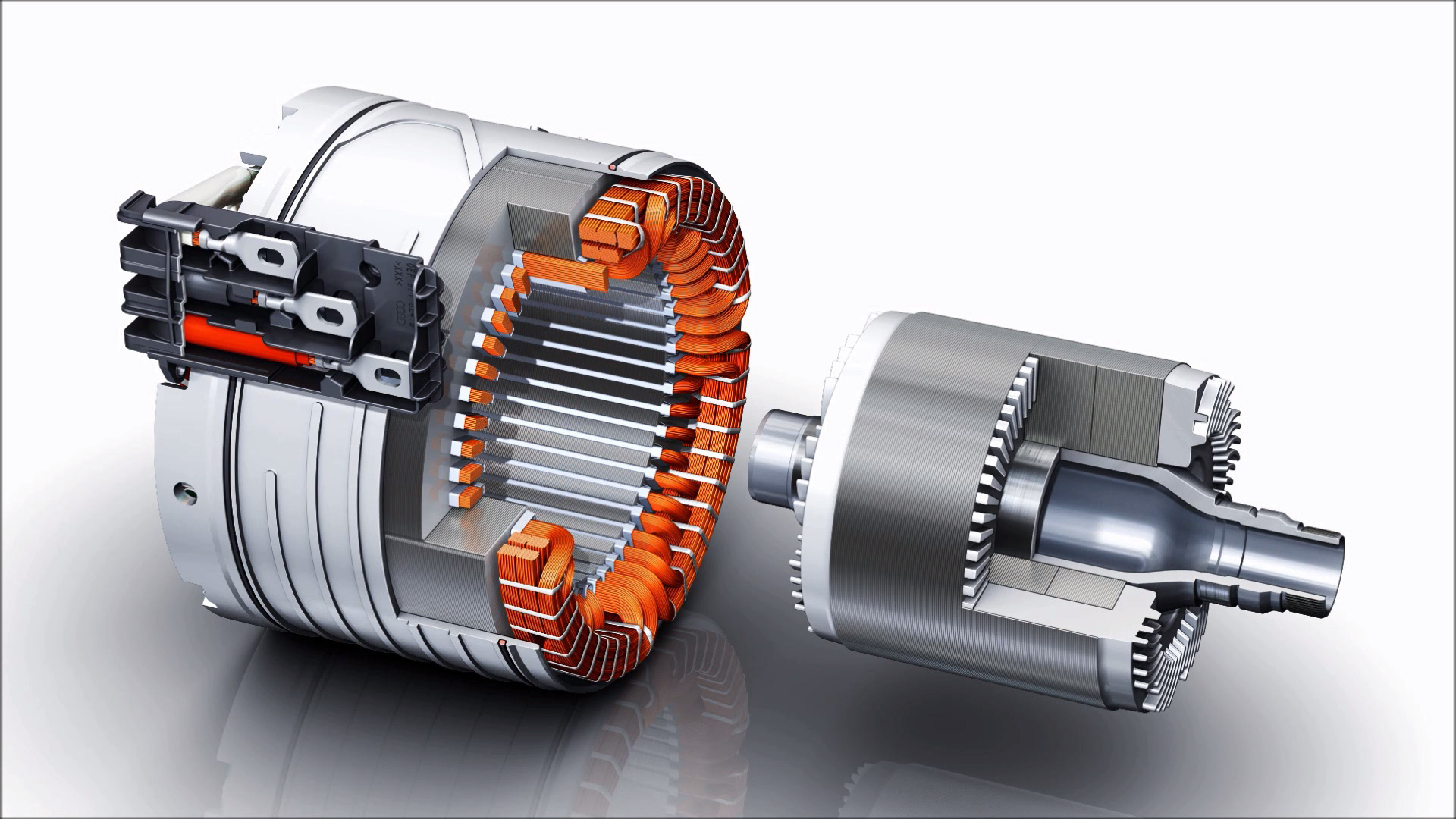

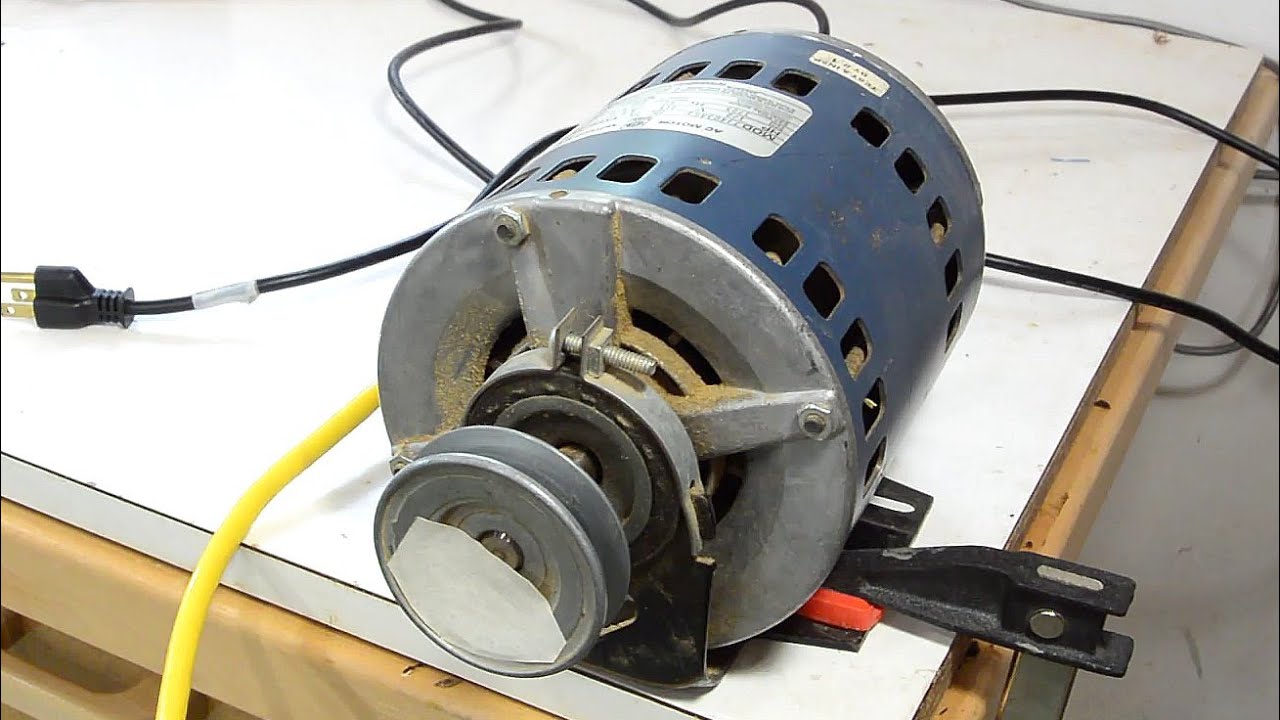

Induction motors possess a very simple induction motor core construction, with the only differences being the stator and rotor. In the induction motor, the rotating magnetic field can be generated through the energized coils of the stator, while the rotor induces currents through electromagnetic induction that produce torque. Unlike synchronous motors, induction motors do not need external excitation devices and complex control systems for their design and manufacturing processes.

This simplicity directly translates to cost-effectiveness. For example, the cost of a typical three-phase induction motor is 20-30% less than other motors of the same power—synchronous or DC motors. In addition, induction motors are much more compact than other types of motors, weighing 10-15% less, thus being ideal for applications where spatial capacity is an issue, such as in HVAC systems or household appliances.

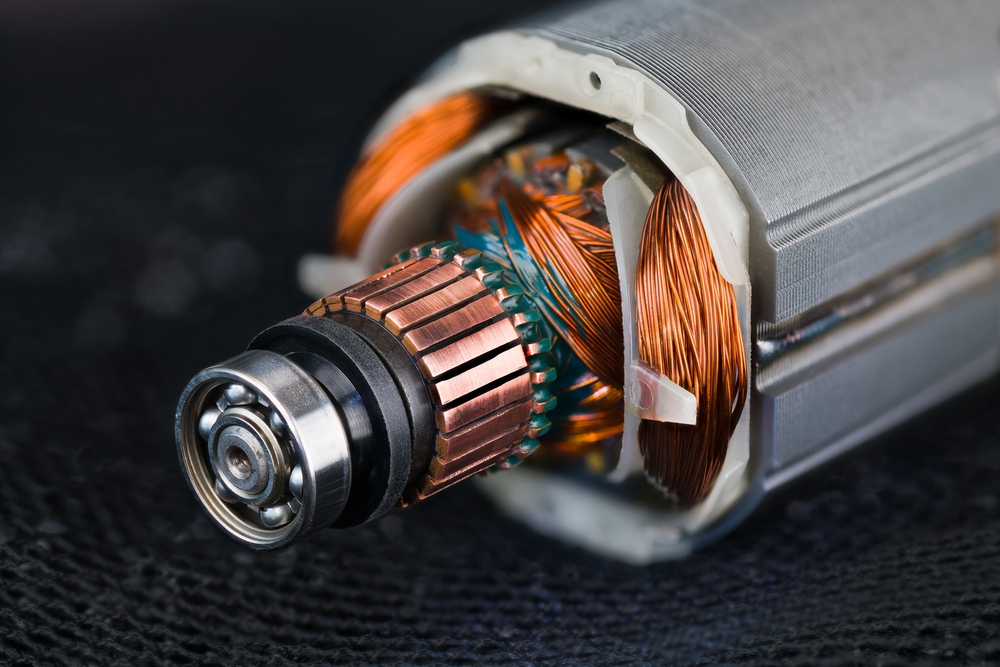

Induction motors are the ones best suited for large-scale industrial applications. For instance, squirrel-cage induction motors incorporate a robust rotor consisting of just copper or aluminum bars with minimal moving parts. According to various statistics, the average life expectancy of squirrel-cage induction motors can easily be 15-20 years, which can save from long-term maintenance needs and replacement costs.

Also, since there are no conventional parts like brushes and slip rings, there will be less mechanical wear. This would not only enhance reliability but also downtime due to the brushing maintenance or replacement, thus why induction motors are preferred in continuous operation applications.

High Reliability

The superior electrical and mechanical structure of induction motors makes them highly reliable. Induction motors need no complex brushes or external excitation devices, which make them suffer from fewer faults due to mechanical friction or poor contact. Research has indicated that in industrial environments, the mean time between failures (MTBF) of induction motors can be greater than 100,000 hours, one of the longest among all types of motor.

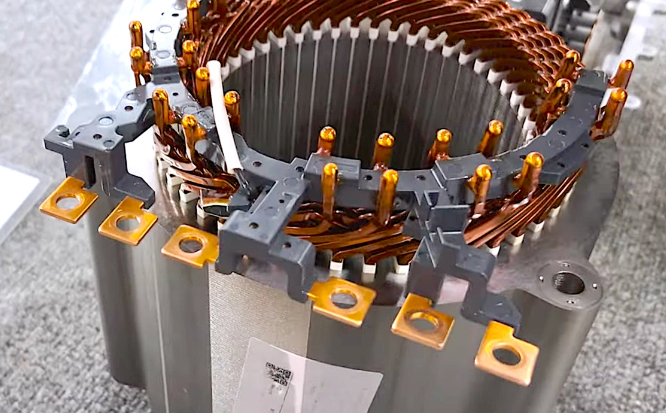

In addition, induction motors employ carefully selected materials. Rotor materials, mostly high-purity aluminum or copper bars combined with silicon steel laminations as the magnetic core, optimize electromagnetic performance and increase resistance to corrosion and heat. For example, an induction motor operating under a high-humidity environment has a rate of performance degradation that is about 30% lower than those of traditional motors when properly maintained.

Induction motors also have superior dynamic stability in performance. Experimental data indicate that an induction motor accepts a sudden increase in load, say from 50% to 100% rated, with speed deviations usually within 2%. This is a real necessity for many industrial machinery applications, including conveyor systems or cranes.

Besides, induction motors can work efficiently in extreme conditions. For instance, induction motors, used in mining equipment, exposed to high levels of dust and vibrations, can often maintain stable operation for more than 10,000 hours. This makes induction motors the backbone in industrial, agricultural, and infrastructure applications.

Low-Noise Operation

Low noise level is another important reason for why induction motors are broadly preferred. Noise mainly takes the origin from electromagnetic, mechanical, and aerodynamic sources, and induction motors are best for these aspects. Without sliding brushes, mechanical noises are greatly minimized. Optimized magnetic field designs also minimize changes in electromagnetic noise, which makes the overall operation quieter.

The experimental data show that for the induction motors running at 1500 rpm, the noise usually made is below 60 decibels, which is as soft as ordinary indoor conversation. Therefore, they are especially suitable for environments that are noise-sensitive such as those found in hospitals, elevators in office buildings, and their use in central air conditioning systems.

Low vibration character is also one of the reasons induction motors provide low noise. Using exact rotor dynamic balance adjustment and high-precision machining, the amplitude of vibration can be kept within 0.01 millimeters. This not only improves smooth operation but also increases the service life of equipment.

Long-term low-noise operation effectively protects other equipment. For instance, induction motors used in factory production lines minimize the impact forces on the surrounding transmission components due to their low noise and vibration characteristics, improving the reliability and life of the entire system.

High Cost-Effectiveness

Induction motors are the first choice for heavy and light industrial equipment and residential appliances due to their high cost-effectiveness. On the initial purchase costs, the mature manufacturing process and economically practical materials of induction motors make them cost-effective. Comparing at the same power level, the purchase cost of induction motors is about 25% less than that of DC motors, and their lifespan can be more than 30%.

Of course, induction motors also have high efficiency in terms of operating costs. For instance, a 90% efficient induction motor, operating 4,000 hours a year and consuming 15 kilowatt-hours of electricity, would save about 1,500 kilowatt-hours compared with an 85% efficient motor. At an average electricity price of 0.6 yuan per kilowatt-hour, that means yearly savings of about 900 yuan.

Maintenance costs also epitomize cost-effectiveness. Since an induction motor is brushless, its maintenance calls for less frequent replacement of part after part that should only be cleaned and inspected. According to statistics, annual maintenance for induction motors runs 30%-50% lower than for synchronous motors, considering the latter’s heavier utilization by businesses.

Moreover, widespread use of induction motors means that the supply chain for spare parts is already mature. This implies that repair materials and technical support are readily available even in areas remote from major industrial areas, which further lowers usage and repair difficulties.

High Energy Efficiency

Such induction motors owe their high energy efficiency to optimized electromagnetic design. In practice, commonly available three-phase induction motors boast efficiencies in the range of 90-95%, with excellent performance under industrial conditions. In reality, high-efficiency induction motors can be enormous energy savers for equipment. For example, for every 100 hours of operation, an induction motor is expected to use about 5% more energy compared to a standard engine.

Induction motors of modern age are having VFD technology, which allows the operating frequency of the motor to be varied with the load demand to increase the efficiency. For instance, in an air compressor where loads vary periodically, variable frequency induction motors with control would save on average 20%-30% in energy.

High-efficiency induction motors are also crucial for environmental protection. Statistics show that globally, if standard induction motors are upgraded to high-efficiency models, that will reduce carbon emissions by annually about 300 million tons of carbon dioxide. This is equal to the emissions of 75 million vehicles.

Stable Performance

The performance stability of induction motors is especially apparent on several aspects. One is the stable operating speed. Even if the load varies, induction motors can continue to operate at near-rated speed. Tests show that the fluctuation in speed is usually in 2%-3% when the load increases from 50% to 120%.

Temperature rise control is another warranty of stable performance. The design takes into consideration the heat dissipation requirements in the development of the induction motors – for instance, the use of high thermal conductivity materials and optimized designs of fan to ensure normal operating temperatures even under high temperatures. Industrial experiments reveal that the temperature rise in induction motors running on ambient conditions of 45°C is less than 60°C.

This induction motor can also respond well to voltage fluctuation on the power grid. Induction motors operate in a stable range even under fluctuating voltage values of ±10% above and below the rated value. Such induction motors are of great use in scenarios where power supply stability is not guaranteed, such as in remote factories or agricultural facilities.

Low Maintenance Requirements

The low maintenance requirement of induction motors follows from their design advantages. Without brushes or slip rings, induction motors less frequently require part replacement after long periods of operation. In contrast, synchronous or DC motors of similar types often require brushing every 1,000 hours.

For most industrial users, induction motor maintenance occurs as periodic inspections and cleaning to, for example, remove dust from stator windings or conduct an insulation performance test. All these are simple operations that are usually done only every six months. Industrial statistics indicate annual maintenance costs of induction motors are 20%-40% lower than those for other types of motors.

To reduce maintenance needs even more, new induction motors are provided with intelligent monitoring systems that can monitor the changing operating conditions in real-time, including temperature, vibration, and current. Thus, early faults can be detected and countermeasures taken ahead of time, thus avoiding production standstills and losses caused by equipment malfunctions.