Description

Product Introduction

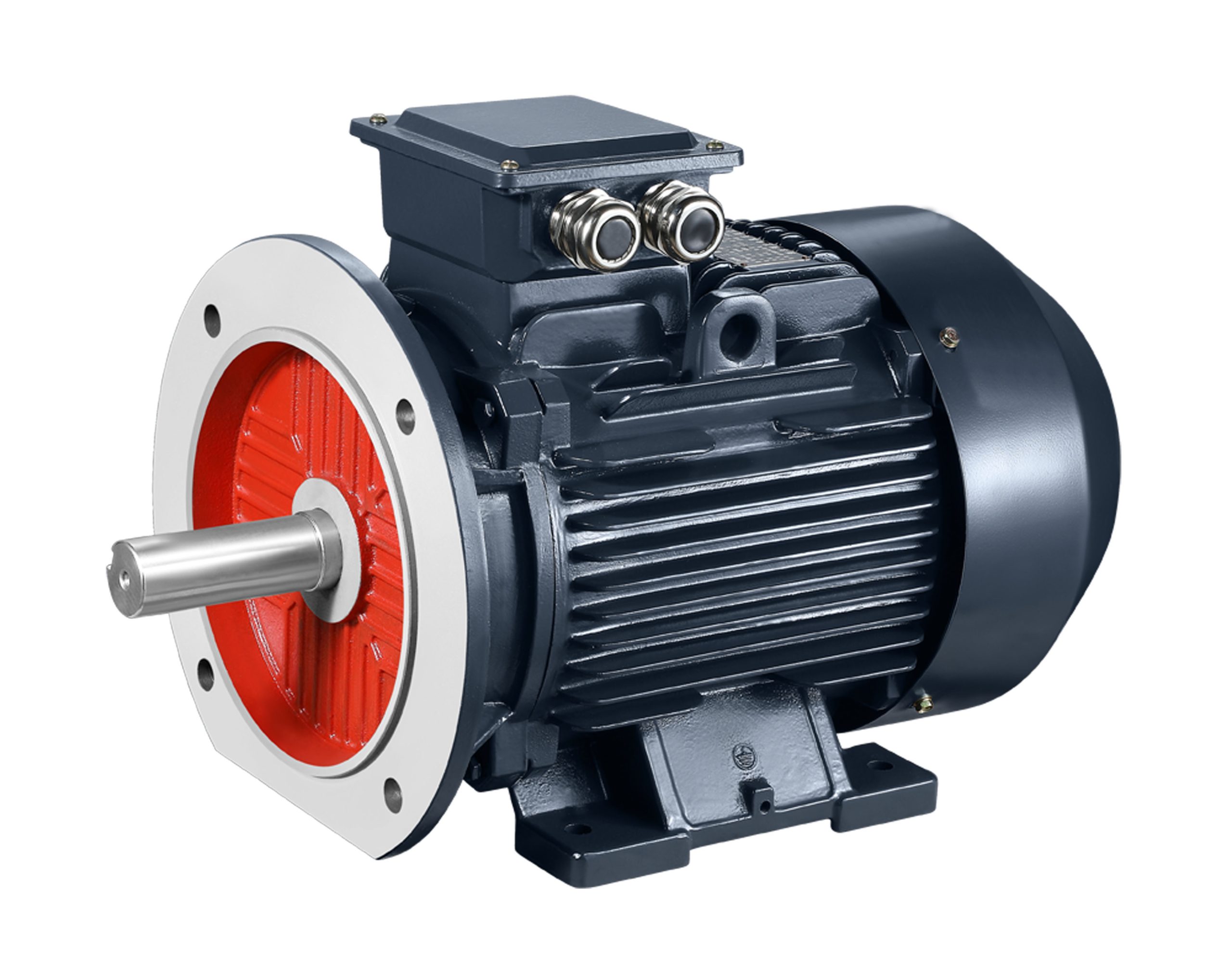

This high-efficient three-phase cast iron housing IE3 (YE3) series motor is designed to satisfy large industrial application requirements. The motors are designed to be operated continuously with high-ecological compatibility.

Cast iron housing motor is special for some conditions such as mines, steel plants, petrochemical facilities, and large manufacturing workshops. Moreover, its high efficiency allows it to be used in energy-saving projects.

The compressors, fans, and pumping systems working with this type of motor are saving much more energy. The outer shell of the product is made up of cast iron, providing a clean and stable inside for the operation of the motor.

It will not be damaged and will remain clean because of this feature. For instance, in high temperature and dusty situations like in a steel plant, a cast shell motor can work properly. In addition, it can save more energy and help a business reduce daily operational electricity costs.

Product Features:

- Cast Iron Housing: The mechanical resistance and the shell protection of the motor by cast iron housing are key performing properties of the product. Chemical plants are the most common environments where cast housings are used. Corrosive gases remain stable inside, which does not affect the application or the lifetime of the motor.

- High-Efficiency IE Standard: With IE3 standards, high-ecologic efficiency reduces electricity consumption compared to lower-efficiency engines. Compressor systems are devices that require reducing electricity, and using the cast iron shell motor in a compressor helps decrease oxygen-electric consumption, which is not used by organisms.

- Long Lifespan Design: The bearing quality and unique heat transfer condensate inside the motor allow it to operate continuously for long hours. The optimized cooling mode prevents overheating, reducing the risk of malfunction. For example, in mining equipment, the motor provides high quality and less downtime.

Wide Range of Application

The large industrial applications of the motor are typical for mining, steel plants, petrochemical facilities, manufacturing workshops, as well as compressors, fan, and pumping systems. These applications do not require the motor to be stopped frequently, allowing it to run smoothly.